Complete production solutions, advanced metal foundries, strict management, and quality inspection processes allow customers to receive mining machinery parts with guaranteed quality and quantity more quickly while enjoying more thoughtful services.

An Excellent OEM Casting Factory

Mining Machinery Parts Manufacturer

-

Parts

-

Benefits

-

Foundry

-

Articles

-

Review

-

Top

Mining Machinery Parts We Have Produced

HULK Metal has provided high-quality OEM services for hundreds of mining machinery accessories brands and produced more than a dozen types of accessories. Here is the tip of the iceberg of our production capabilities. Kindly contact our sales manager.

The teeth of crushing equipment, hammerheads, drill bits of drilling equipment, and other components are produced using casting. Construction machinery, such as excavators, forklifts, etc., are also used in mining processes. Many of the accessories of these construction machinery are cast and produced, such as the teeth on the bucket. The above-mentioned parts that have high requirements on wear resistance, hardness, etc., and need to be replaced regularly after wear and tear generally use ductile iron as the raw material. Other components need to be determined based on specific requirements. The casting process used to complete production needs to be determined based on the shape, size, surface accuracy, and performance requirements of the castings. Kindly contact our engineers if you have mining machinery accessories that you need OEM. They will develop solutions that meet quality requirements at a lower cost.

Benefits Let HULK Metal Manufacture Mining Machinery Parts

By placing your order with HULK Metal, you can receive goods that meet quality requirements faster, enjoy high-quality service and save more time and energy. Kindly contact our sales manager to experience one-to-one service.

-

Higher Quality Orders

-

Save More Money

-

Get Goods Faster

-

Safe More Time and Effort

-

Higher Quality Orders

ISO 9001 quality certified foundry, strict production management, advanced casting equipment, experienced technology, production, quality inspection team, and rigorous quality inspection process enable us to have the ability to complete higher-quality orders. You can send us the drawings. Our team will customize a solution that meets your quality requirements.

01 -

Save More Money

We will develop more suitable solutions according to your requirements, select a more suitable casting process, and optimize the production process to save material costs, process costs, labor costs, etc. A complete supply chain can save the cost of the entire order from multiple links. You'll find you can save even more by leveraging our supply chain.

01 -

Get Goods Faster

We will plan a more reasonable production process based on delivery time requirements to ensure that each order can be delivered on time. Our freight consulting team can find a more suitable freight company to achieve perfect connection of goods. A sound supply chain is a prerequisite for us to always complete delivery on time. You can trust us with your order.

01 -

Safe More Time and Effort

We have established a team including technology, procurement, production, quality inspection, design, logistics, freight consulting, after-sales and other personnel. We will provide one-to-one service and solve your various questions at any time. Provide order tracking and development, cargo tracking and other services. Provide guarantee services for product quality. Help you save more time and energy through comprehensive services.

01

Here, we list factories, mold manufacturing, metal foundries, casting processing plants, etc. in the supply chain. These are some of the reasons why we can provide more thoughtful mining machinery parts production services. Kindly contact our sales manager if you would like more.

Mold Making Factory

Metal Casting Foundry

Machining Castings Factory

-

Mold Making Factory

After selecting the appropriate casting process, you need to complete the production of molds, including sand casting Models, Metal Molds for die casting, wax molds for investment casting, and foam molds for lost foam casting. Make samples and adjust the mold according to the size, appearance, surface accuracy and other results of the test samples until they are finally qualified.

-

Metal Casting Foundry

ISO 9001 certified sand casting, investment casting, lost foam casting factory with advanced equipment and experienced team. No matter which casting process is used, better casting services can be provided. Investment casting plants are more suitable for producing stainless steel, alloy steel, carbon steel and other castings that have high raw material costs, high dimensional and surface accuracy requirements, complex structures and smaller castings. Sand casting is suitable for cast iron, ductile iron, gray iron and other castings with low material cost, low surface precision requirements and simple structure. Lost foam casting is more suitable for castings with high surface precision.

-

Machining Castings Factory

Our advanced machining equipment can machine castings to tolerances as low as 0.05µm. We have three-axis, four-axis, and five-axis machining centers, and we can choose the more suitable one according to needs to complete orders to reduce the cost of mining machinery parts. For simple processing of tapping and hole expansion, ordinary machine tools can be used to complete it.

Articles About Mining Machinery Parts

We have listed here some articles on Mining Machinery Parts materials, production processes, and testing methods. We've also prepared some breaking news from the technical team. Kindly send drawings to us if you need OEM service. We will develop a solution that makes you more satisfied.

-

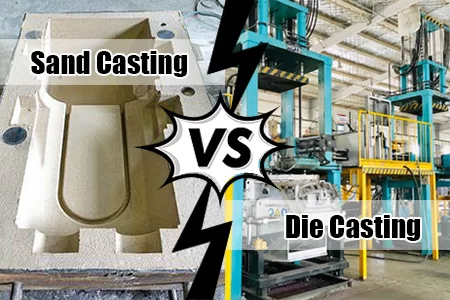

March 26, 2025

Sand Casting vs. Die Casting: Which is Right for Your Project?

READ MORE

-

March 10, 2025

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

READ MORE

-

March 03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE

-

February 25, 2025

How to Compare Product Quality Between Different Casting Foundries?

READ MORE

-

February 14, 2025

What Are The Metal Casting Materials Commonly Used in Foundries?

READ MORE