HULK Metal has 20 years of investment casting experience and has provided investment casting services to more than 20 industries, such as machinery manufacturing, home appliance manufacturing, and construction. We have an advanced investment casting found

HULK Metal

Better Investment Casting Services Supplier

-

Advantages

-

Capacities

-

Processes

-

Parts

-

Types

-

Foundry

-

Introduction

-

Articles

-

Review

-

Top

START INVESTMENT CASTING SERVICES AT HULK METAL.

HULK Metal has an advanced investment casting foundry and quality control center. We have accumulated rich investment casting service experience and will continue to break through ourselves to provide customers with better services. You can contact us for a suitable solution.

-

Foundry:

HULK Metal's die-casting foundry is ISO 9001 certified. The die-casting workshop has ten sets of die-casting machines, one each of 4500 tons, 2500 tons, and 1600 tons; it has eight machining centers and 26 CNC machine tools; it has a welding center, a surface treatment center, and a quality control center. We have sufficient production capacity to receive large-volume orders. Because the cost of making die-casting molds is relatively high, investment casting can be used instead of die-casting to complete the order when necessary. We will develop a perfect solution based on your drawings.

-

Experience:

We only provide aluminum die-casting services and can produce aluminum die-casting parts from ADC1,3,5,6,10,12,14aluminum alloy. We have provided high-quality solutions for the communications industry, home appliance manufacturing, furniture manufacturing, power transmission industry, lighting manufacturing, automobile manufacturing, etc., and delivered tens of thousands of orders. If you want to find a die-casting foundry to complete your order, you can contact us for a free quote and solution.

-

Quality:

The quality control center has complete quality inspection equipment such as CMM, electron microscope, flaw detector, salt spray test room, chemical testing equipment, hardness tester, thickness meter, etc. We can detect the size of the product, pores, chemical composition, corrosion resistance, coating thickness, surface gloss and color difference, etc. We will develop quality inspection plans and issue material and product testing reports based on customer requirements.

-

Service:

Our service center provides technical support to develop a complete solution based on your required delivery time, delivery method, order quantity and drawings, and complete price calculations. We support on-site and on-site factory visits, support a variety of delivery methods, and can ship worldwide. We provide after-sales service and quality assurance service. Providing high-quality services is our service tenet. We will humbly accept your suggestions and continue to improve.

INVESTMENT CASTING SERVICES CAPACITIES

Here, we introduce the investment casting services we can provide in terms of materials, processes, piece weight, production capacity, certification, and processing. We can develop a complete solution based on drawings or samples and calculate a great price. Contact us now and let our engineers customize a price-inclusive solution.

MANUFACTURING: | According To the Drawings Or Samples |

Service Method: | OEM |

MATERIALS: | Ductile Iron, Malleable Iron, Gray Iron, Carbon Steel, Stainless Steel, Brass, Aluminum and Its Alloy |

PROCESS: | Silica Sol, Water Glass, Resin |

WEIGHT: | <=500 Tons/piece |

PRODUCTION CAPACITY: | 500 tons/month |

CERTIFICATION: | ISO 9001, IATF 16949 |

FINISHING: | CNC Machining, Surface Treatment |

MOQ: | 500KG / A Standard Tray |

HOW YOUR INVESTMENT CASTINGS PRODUCED

Here, we will introduce how to use the investment casting process to complete the production, quality inspection, packaging, and delivery of castings. Of course, this is just a brief description. If you want to know the specific process, kindly contact our engineers.

-

01

Customize Solutions

Before the order starts production, we will develop a complete solution according to your requirements and discuss its feasibility with you. After getting your agreement, we will begin mold manufacturing and sample trial production.

-

02

Mold Making

Investment casting mold mainly refers to the mold for making wax patterns. The material of the mold is aluminum alloy and steel. The production process includes measuring drawings, making molds, trial-producing wax models, trimming molds, and putting them into use.

-

03

Wax Pattern Making

Make the mixed wax into a wax tree by pressing, cooling, trimming, and treeing assembly. Because the characteristics of wax make the wax pattern and the workpiece very similar, investment casting can produce more complex and higher-precision castings.

-

04

Shell Making

Dip the assembled wax mold in slurry. Coat the powder, air-dried, melt the wax recycle it, and bake to obtain the mold shell. This is one of the important processes of investment casting. Contact us to learn more.

-

05

Pouring

Pour the liquid metal into the mold shell along the pouring opening, and the mold shell will emit bright light, which is very beautiful. Wait until the whole thing cools down before proceeding to the next process.

-

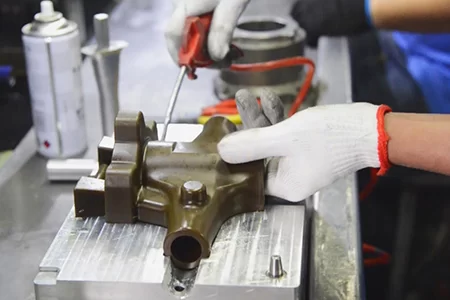

06

Cutting and Cleaning

Brake the mold shells, take the castings out, pass cutting, and shoot blasting. We can obtain the semi-finished product of the investment castings.

-

07

Heat Treatment

The purpose of heat treatment of castings is to improve mechanical properties and corrosion resistance, stabilize dimensions, and improve process properties such as machinability and weldability. Whether carry out this process needs to be decided based on the performance requirements of the casting.

-

08

Finishing

Use the CNC Machining to adjust the shape and size of semi-finished products further. The finished product is then obtained through surface treatment processes such as powder spraying, galvanizing, and polishing.

-

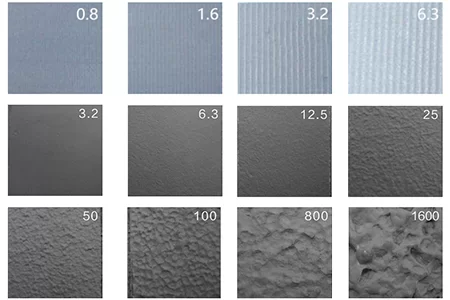

09

Quality Control

We will complete the inspection of the castings' shape, size, surface roughness, hardness, ductility, brittleness, and other aspects according to requirements and issue material and product testing reports.

-

010

Packaging & Delivery

We provide wooden boxes, cardboard boxes, and other packaging materials boxes. Styrofoam and bubble paper are used to fill between products. We can also customize according to customers' requirements. Find better freight companies for faster delivery by the freight consulting services we provide.

-

011

After Service

We will provide comprehensive after-sales service to ensure the overall quality of the order. We hope that our customers will provide valuable feedback on our services, which is the source of our continuous improvement.

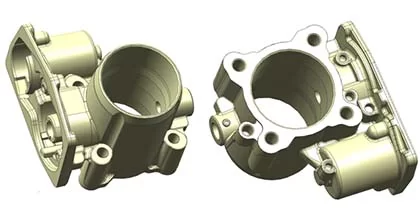

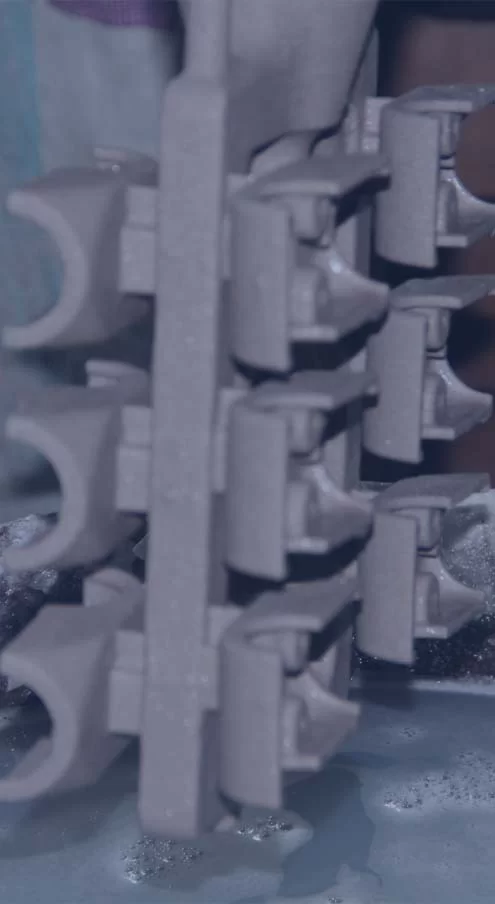

PARTS HULK METAL INVESTMENT CASTING FOUNDRY PRODUCED

These are our finished products using investment casting. The pictures are all from the Internet, and we will not give customer information to anyone without permission. Contact us now, and our engineers will customize a perfect solution and a great price based on the drawings.

More Results

INVESTMENT CASTING TYPES HULK METAL CAN SUPPLY

Here, you will find the investment casting services you are more interested in based on materials. We can complete castings made of ductile iron, gray iron, stainless steel, carbon steel, copper, and aluminum alloys. Contact us for solutions and quotes.

Aluminum Investment Casting

Brass Investment Casting

Investment Casting Steel

Stainless Steel Investment Casting

-

Aluminum Investment Casting

When our order quantity is small, the mold manufacturing cost of die casting will be very high, and sand casting cannot meet the casting accuracy. In this situation, we can choose investment casting with relatively low mold cost and higher precision to complete the order. HULK Metal will develop a complete production solution based on your drawings and specific requirements and calculate a better price. Contact us now to visit the factory and place your order.

-

Brass Investment Casting

When the shape of copper castings is complex, precision requirements are high, and it is difficult to reprocess the rough blank using sand casting, it is necessary to use investment casting to complete the order. This can not only reduce the cost of the order but also shorten the lead time of the order. An experienced investment caster will develop a perfect solution based on the drawings and requirements and calculate a better price. Contact us now, and we provide it for free.

-

Investment Casting Steel

This is a process of using steel as a material to use investment casting to complete workpieces with complex shapes and stricter tolerances and surface roughness requirements. Steel mainly refers to low-carbon, medium-carbon, high-carbon, stainless steel, and alloy steel. When our investment foundry receives your request, we will develop a complete solution and provide you with the right price. Contact us to visit the factory online or offline.

-

Stainless Steel Investment Casting

Workpieces made of stainless steel, with relatively complex appearances and strict tolerance, require investment casting to be produced. The cost of stainless steel is relatively high. And if defective products occur, the order cost will be significantly increased, which neither the foundry nor the purchaser is willing to face. Castings of most grades of stainless steel, such as 304, 304L, 316, 316L, etc., can be completed by investment casting. Contact us now. Our engineers will develop a perfect plan based on your requirements and calculate a better quotation.

VISIT HULK METAL INVESTMENT CASTING FOUNDRY

Here is a brief introduction to one of the reasons why we can provide high-quality investment casting services - the foundry. Our foundry strictly implements ISO 9001 and has advanced equipment, rigorous processes, and strict management. The experienced production team is also unmatched by other factories. Kindly contact our engineers if you want to visit our factory online or in person.

-

Equipment of Investment Casting Foundry

The factory has advanced wax pressing machines, dipping machines, wax melting equipment, shell-burning equipment, pouring equipment, shot blasting, and cutting equipment. This lays the foundation for better completion of orders.

-

Production Team

Our production team has rich experience and can complete orders efficiently while ensuring the order qualification rate.

-

QC Center of Sand Casting Foundry

Our quality inspection center can complete most casting inspections and will issue complete material and product inspection reports as required.

INVESTMENT CASTING SERVICES INTRODUCTION

Here, we will briefly introduce the knowledge of investment casting, such as what investment casting is and the advantages and disadvantages of investment casting. At that time, we also briefly explained the benefits you can get by choosing HULK Metal's investment casting services.

-

Investment Casting Means:

Investment casting is a casting process that uses wax as a mold to produce workpieces. The primary operation is to use special wax to make a mold that is the same as the workpiece, wrap the wax mold with a layer of slurry prepared with adhesives, plaster, and other substances, then dry it, heat it to melt the wax and pour it out to obtain the mold shell. , bake the molded shell to reach a certain hardness, melt the metal and pour it into the molded shell, crush the molded shell after cooling, and then go through cutting, shot blasting, heat treatment, and finishing to obtain the desired workpiece. Industrial investment casting mechanizes this process, making it more efficient and enabling mass production.

-

Advantages and Disadvantages of Investment Casting:

Advantages:

1. Almost all metals can be cast; 2. Castings can be more complex and more precise; 3. Castings rarely need to be processed again.

Disadvantages:

1. Due to process limitations, there will be pores inside the casting; 2. Compared with sand casting, the process is complex, and the cost is higher; 3. Only tens of kilograms of castings can be processed; 4. The production cycle is longer.

What You will Get When Choose Our Investment Casting Service.

Our professional investment casting service supply chain can complete solution customization, price accounting, raw material procurement, production, quality inspection, packaging design, warehousing, freight consultation, and after-sales full-process services. Choose our investment casting service, and your order can be completed faster with guaranteed quality and quantity at a lower cost.

ARTICLE OF INVESTMENT CASTING

Here are articles about investment casting that we have collected and organized. They cover the knowledge of investment casting, including raw materials, types, advantages and disadvantages, processes, etc. We also did some supplier comparisons. We hope you gain something.