Exceptional metal casting services start with top-notch mold making. We can provide mold manufacturing services for various metal casting processes such as die casting, investment casting, and sand casting.

HULK Metal

Top Making Mold For Metal Casting

-

Home>

-

Mold Making>

-

Capacities

-

Processes

-

Industries

-

Foundry

-

Benefits

-

Services

-

Introduction

-

Articles

-

Review

-

Top

MOLD MAKING SERVICE CAPACITIES

Here, we will introduce the mold manufacturing services we can provide. Mold manufacturing for metal casting needs to be considered based on casting accuracy, casting process, mold material, and other aspects. Contact our engineers for more details.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Cold Work Die Steel, Hot Work Die Steel, Customizable |

Molds for Casting:

| Sand Casting, Investment Casting, Die Casting, Lost Foam Casting |

Process: | CNC Machining, Heat Treatment |

PROCESSES OF YOUR METAL CASTING MOLD PRODUCED

Here, we mainly talk about the production process of your metal casting mold. The mold is a very important tool in metal casting because it affects the shape and size of the casting. If you want to know more about mold manufacturing, you can contact our engineers.

-

01Analyze Drawings & Customize Solutions

01Analyze Drawings & Customize SolutionsDetermine the product requirements, shape, size, and tolerances according to the drawings, and determine the structure, specifications, and number of cavities of the mold. Calculate the final price and develop a solution.

-

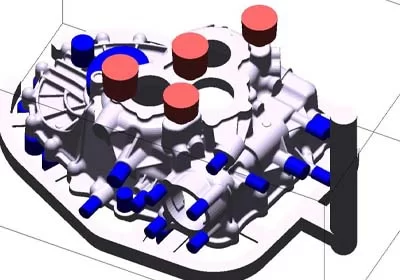

02Draw Mold Drawings

02Draw Mold DrawingsDraw the 2D layout diagram, mold runner diagram, 3D mold diagram and mold parts diagram required for mold production based on the main structure of the mold in the solution.

-

03Raw Material Purchasing

03Raw Material PurchasingPurchase mold blanks and supporting parts needed for mold manufacturing. Die-casting molds need to purchase sprue sleeves, diverter cones, DH31S, shape parts, cylinders, ejector pins, insert pins, exhaust pipes, etc.

-

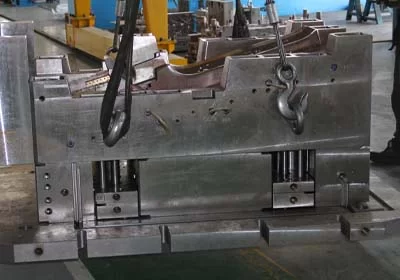

04Mold Processing

04Mold ProcessingComplete the initial processing of the mold according to the drawings, improve the strength of the mold through heat treatment, and then complete the size adjustment and optimization through finishing. The optimized mold can be used for the next item.

-

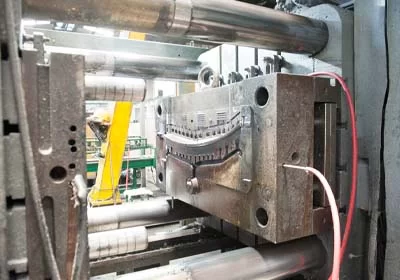

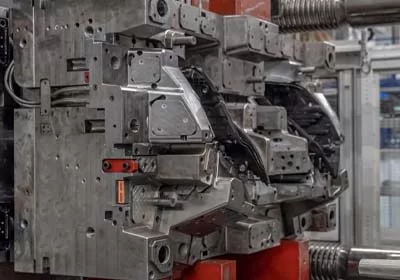

05Assembly & Commissioning

05Assembly & CommissioningInstall the completed mold to the die casting machine, wax mold die casting machine, and sand casting machine for debugging. Make sure all parts on the mold are functioning properly.

-

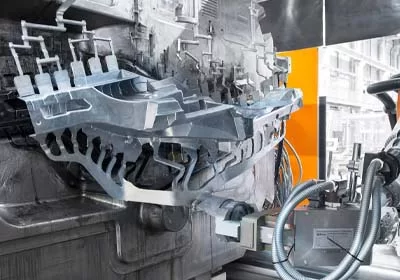

06Trial Production

06Trial ProductionAfter mold debugging, trial production is required to ensure that the aluminum die castings, wax molds, and sand casting molds produced meet the requirements.

-

07Deliver or Start Orders

07Deliver or Start OrdersAfter completing the mold production, we will complete the mold delivery. If your casting order is placed with us, we will start production of the order.

-

08After Service

08After ServiceWe will provide comprehensive after-sales service to ensure the normal use of the mold. If we produce metal castings, we will save every mold and do a good maintenance job.

START MAKING MOLD FOR METAL CASING AT HULK METAL

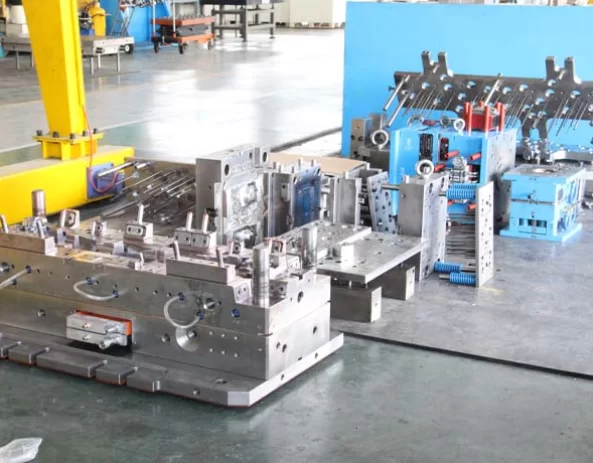

Professional engineers, advanced mold manufacturing factories, strict production processes, and perfect services are the basis for us to provide complete metal casting mold manufacturing services. If you are also looking for such a supplier, kindly contact us.

-

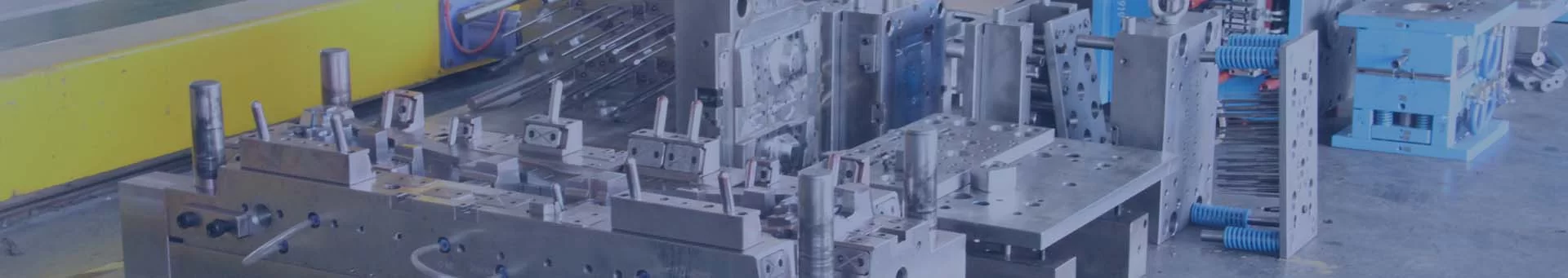

Factory

HULK Metal has milling machines, mold machines, drilling machines, lathes, CNC machining centers, wire-cutting machines, spark machines, and other mold manufacturing equipment. We can produce molds with a precision of 0.001mm and higher complexity. We have made molds for use on 4500-ton die-casting machines, wax molds for use on wax press machines, and molds for mechanical sand-casting machines. You can contact us to visit factory.

-

Experience

As of today, we have provided mold manufacturing services and high-quality metal casting services for more than 20 industries, including automobiles, textile machinery, food machinery, mining machinery, agricultural machinery, home appliances, furniture, and other manufacturing and construction industries. We cannot disclose the information of customers we have served, but we can develop free solutions according to your requirements. If you are satisfied, we will cooperate again.

-

Quality

Our quality control center has inspection tools such as calipers, calibration meters, bore gauge detectors, depth micrometers, and 3D scanners, as well as experienced quality inspectors and strict quality inspection processes. We can develop a complete quality inspection plan according to your requirements. We have been recognized by hundreds of factories. You can contact us with confidence.

-

Service

Metal casting mold making is just one part of our supply chain. We have successfully integrated and split the supply chain to meet the various needs of our customers. We can provide raw material procurement, mold making, metal casting, quality inspection, customized packaging, freight consulting, and other services. If you require metal casting services, kindly contact us. Our engineers will provide solutions for free and at a premium price.

METAL CASTING TYPES HULK METAL CAN SUPPLY

Here, we will introduce the types of metal casting services we can provide in detail, such as sand casting, investment casting, die casting, and some material-related casting services. You can click to learn more according to your needs.

-

Investment Casting Service

-

Lost Foam Casting

-

Sand Casting Service

-

Investment Casting Service

Investment casting service is a process in which a foundry uses wax patterns to complete metal casting orders through tree assembly, dipping, powder coating, air drying, melting wax, roasting, casting liquid metal, shelling, finishing, and other processes. Castings produced by investment casting have smaller Ra values and higher precision than sand casting. However, the process is more complex and can produce castings with smaller weights and relatively higher cost. We can decide whether to use investment casting to complete the order according to the castings' requirements. We can develop solutions, calculate prices, and complete the production and delivery of orders for you.

-

Lost Foam Casting

Aluminum casting services are a process in which foundries process aluminum and its alloys into castings of specific shapes, sizes, and properties using sand casting, investment casting, gravity casting, and other processes. Because it involves mass production, the entire process can improve production efficiency, shorten lead time, increase the qualification rate of aluminum castings, and reduce production costs after being better optimized. Therefore, a good aluminum casting service provider needs to be familiar with various processes and be able to give better solutions.

-

Sand Casting Service

Sand casting service is a process in which foundries use siliceous sand, zircon sand, chromite sand, etc., and clay, resin, and water glass as binders to make molds and complete the production of metal castings. Sand casting has more ways to produce orders. The castings are bigger, and the price is lower, but the castings' surface roughness and precision are lower than other casting processes. Whether casting is suitable for sand casting production requires consideration of the characteristics and requirements of the workpiece itself, so a professional metal service foundry will select a more suitable casting process based on your drawings and requirements to develop a solution and complete the order.

MOLD MAKING OF METAL CASTING INTRODUCTION

Here, we will introduce some content of mold manufacturing used in metal casting, what is a casting mold, types and materials of casting molds, etc. It also explains the benefits you can get when choosing our mold manufacturing services. If you want to know more, kindly contact our engineers or browse Blog.

-

Mold Making of Metal Casting Means

Mold Making of Metal Casting is a process in which we use various materials to create a mold that can form a cavity for pouring liquid metal during the casting process. Sand casting requires molds to be filled and then taken out to form cavities, investment casting requires molds to create wax patterns, and die casting requires pre-made metal molds to be closed to form cavities. If you want to learn more about mold manufacturing, kindly contact our engineers.

-

Type of Molds of Metal Casting

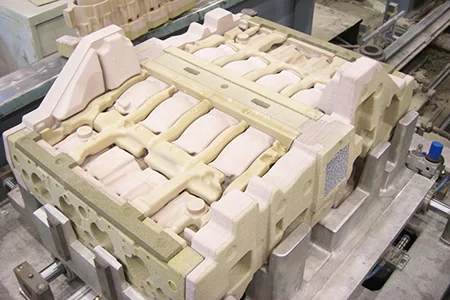

Metal Molds:

A mold made of metal is made up of multiple structures. After the mold is closed, a cavity is formed, leaving a pouring port to facilitate the entry of liquid metal.

Max Mold:

Using metal first makes a mold that can be pressed into the same wax pattern as the metal casting. Wax patterns are then mass-produced for investment casting.

Sand Mold:

Using molding sand, molds, and cores to make casting molds. There is a pouring opening on the casting mold, and the cavity inside is the same as the metal casting.

In addition to the above three common casting molds, there are also ceramic molds, plaster molds, etc. You can contact us to learn more.

What You will Get When Choose Our Mold Making of Metal Casting Service.

You can get more discounts if you choose our metal casting services while choosing us to make molds. We can develop a solution with a shorter lead time for free. Our freight consulting team can help you find a better freight company and save you more energy. Contact us now and let our engineers help you design a satisfactory solution.

Hulk Metal is committed to providing higher standards of products and services for hardware customers. You will get our best products and metalworking services in Hulk Metal.