HULK Metal has an experienced team, rigorous service processes, advanced investment casting plants, and a complete supply chain to provide better investment casting services. Kindly send us the drawings and get a more suitable solution and a more competit

Supply better Investment Casting Service

Excellent Investment Casting Foundry

-

Introduction

-

Equipment

-

QC Center

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

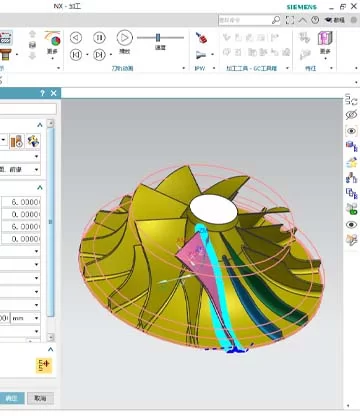

An excellent investment casting company will obtain your drawings and requirements, plan the investment casting process based on the castings' surface accuracy, shape, and performance to complete the order better, and then formulate a perfect production solution and provide quotations based on the delivery method and delivery time. The prerequisite is understanding investment casting fully and having a complete supply chain. HULK Metal has all the above factors. You can contact our sales manager to verify.

INVESTMENT CASTING FOUNDRY PRODUCTION LINE

Here is our equipment and production display. Customers also see these when they visit our factory. This is the basis for us to provide customers with high-quality investment casting services. Kindly contact us. We will take you to visit the factory on-site or online.

QUALITY CONTROL CENTER

Our quality control center has advanced three-dimensional coordinate testing, hardness tester, impact testing machine, spectrometer, salt spray tester, tensile testing machine, and other testing equipment. Kindly contact our sales manager if you want to visit our factory. They will take you to visit them online or in person.

-

CMM

It can more accurately measure the shape and size of lost foam castings.

-

Electron Microscope

Detect the internal structure and pore distribution of lost foam castings clearly to see if they meet the casting requirements.

-

Hardness Tester

Has Brinell and Rockwell hardness testers. Meet various requirements for hardness measurement.

-

Impact Tester

It is used to measure the resistance of lost foam castings to high-speed loads under different environmental conditions.

-

Salt Spray Test Machine

Place the casting in a simulated environment to test its oxidation resistance, corrosion resistance, etc.

-

Spectrograph

Detect the types and contents of elements in castings.

-

Tensile Testing Machine

Complete various tests such as tension, compression, bending, shearing, peeling, tearing, and two-point extension of lost foam castings.

HOW INVESTMENT CASTING FOUNDRY COMPLETE YOUR ORDER

Here we briefly describe the process by which an investment foundry produces your order after receiving it. From solution formulation, production samples to final goods delivery and after-sales service. Kindly contact our sales manager. He will take you on a tour of the factories and describe them in detail.

-

PART 01Custom A Suitable Solution

PART 01Custom A Suitable SolutionDesign a suitable investment casting solution based on the casting drawings, delivery method, and delivery time and calculate a more competitive price.

-

PART 02Make Samples

PART 02Make SamplesSamples are produced using the process described later and tested as required. Samples will also be sent to you for testing. After passing the test, production will be scheduled and mass produced.

-

PART 03Order Scheduling

PART 03Order SchedulingDuring the production scheduling process, we will make more reasonable arrangements for raw material procurement to facilitate the production of orders, and optimize the investment casting process to further improve production efficiency.

-

PART 04Mold Making

PART 04Mold MakingIt refers to the production of pressed wax molds. Processes such as wax injection, pressing, and cooling can be completed faster. Its materials include stainless steel (expensive), carbon steel (medium), and aluminum alloy (cheap).

-

PART 05Trimming and Welding

PART 05Trimming and WeldingThe pressed wax mold needs to be repaired with burrs and flash edges using a carving knife, and then welded to the wax tree with a gate using iron. Welding needs to leave allowance for cutting and grinding. After drying, proceed to the next step.

-

PART 06Dipping, Flouring and Drying

PART 06Dipping, Flouring and DryingPut the wax tree in a paint bucket to evenly coat the paint, then put it into a sand bucket to evenly coat the sand. Place it in a drying room to air dry.

-

PART 07Repeat the Previous Step Multiple Times

PART 07Repeat the Previous Step Multiple TimesRepeat the above steps until the shell thickness reaches the specified requirements.

-

PART 08Dewaxing and Roasting

PART 08Dewaxing and RoastingUse high temperature to melt and evaporate the wax in the mold shell, and then put the mold shell into a high temperature environment of about 1000°C to bake to obtain a mold shell that can be used for pouring.

-

PART 09Metal Smelting

PART 09Metal SmeltingThe metal smelting process is relatively complex, and the timing and order of adding various auxiliary materials are required. I won’t go into details here, and those who are interested can look it up on their own.

-

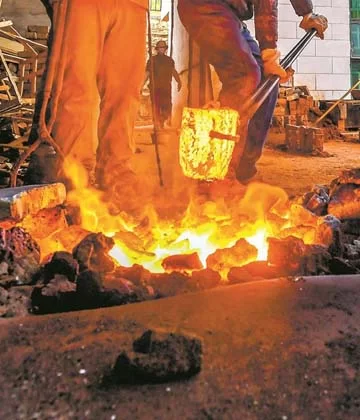

PART 10Pouring & Cooling

PART 10Pouring & CoolingThe pouring process needs to be determined based on the properties of the casting, the properties of the metal and other factors. The speed and temperature of liquid metal entering the mold shell need to be strictly controlled. After pouring, let it cool.

-

PART 11Cleaning

PART 11CleaningAfter removing the mold shell, shot blasting and cutting to remove the gate, a semi-finished investment casting is obtained.

-

PART 12Heat Treatment

PART 12Heat TreatmentWhether to heat treat or not needs to be determined based on the performance requirements of the casting and which heat treatment method to use needs to be determined based on the material.

-

PART 13Finishing

PART 13FinishingAfter heat treatment, the castings are machined as needed, and the surface and shape are finally adjusted to obtain finished parts that meet the standards in size, surface accuracy, performance, etc.

-

PART 14Packaging & Warehousing

PART 14Packaging & WarehousingDesign exquisite packaging according to needs and provide a variety of packaging materials to give customers more options. Strictly managed warehouses can better preserve goods.

-

PART 15Delivery and After Service

PART 15Delivery and After ServiceWe have a freight consultation center that can help customers screen freight and logistics companies. Find better shipping options for faster delivery. After-sales service ensures the quality and quantity of goods and provides other free value-added services.

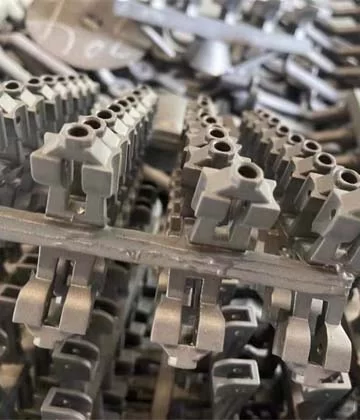

INVESTMENT CASTING PARTS WE HAVE PRODUCED

Here, we show the investment castings we have produced, made of materials such as stainless steel, carbon steel, iron, aluminum, brass, etc., which have been applied to pipes, decoration, construction, machinery manufacturing and other industries. Kindly contact our engineers if you have castings that need processing. He will provide you with excellent service.

More Results

CHOOSING HULK METAL AS INVESTMENT FOUNDRY YOU WILL GET

You can get the following four main benefits from HULK Metal. You can contact our sales manager to get a complete solution and price to check whether what I say is true.

-

Get Higher Quality Castings

Our investment casting factory strictly implements the ISO 9001 quality management system. Strict production management, advanced equipment, and experienced workers are the basis for producing high-quality castings. Kindly contact our sales manager to visit the factory.

-

Get Goods Faster

A more efficient production process, higher yield, and shortened order delivery cycle. Our freight consulting team has helped thousands of companies find suitable freight companies to achieve faster delivery of goods.

-

Spend Less Money

The larger your order, the more efficient our supply chain can operate and save more costs. We will share this profit with you, allowing you to spend less money.

-

Spend Less Time & Energy

We have established a service team including technology, procurement, production, quality inspection, freight and after-sales service personnel to provide one-to-one service. Regularly report order progress, cargo transportation progress, etc. to solve various problems after receiving the goods. Help you save more time and energy.

ARTICLES OF INVESTMENT CASTING FOUNDRY

Here is relevant content about investment casting foundries, a detailed introduction to the investment casting process, and the metals and grades that can be cast. And how to find a more suitable investment foundry. Kindly contact our sales managers if you require investment casting services. They will specify a complete production solution for you and offer better prices.

-

March 12, 2025

Applications of Stainless Steel Castings in Medical Devices

READ MORE

-

March 10, 2025

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

READ MORE

-

March 03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE

-

February 14, 2025

What Are The Metal Casting Materials Commonly Used in Foundries?

READ MORE

-

January 09, 2025

How to Select The Right Raw Materials for Casting Foundries?

READ MORE