Machining brings the casting closer to the required shape, size, and surface roughness. Professional machining services require more precise tools and machining centers. HULK Metal has these.

HULK Metal

Top Machining Castings Services

-

Capacities

-

Industries

-

Introduction

-

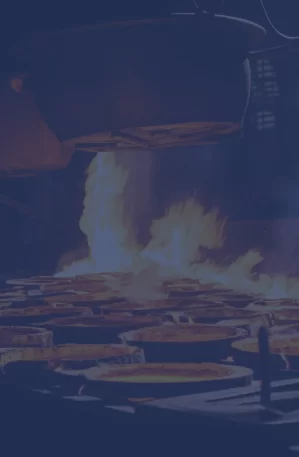

Foundry

-

Benefits

-

Process

-

Articles

-

Review

-

Top

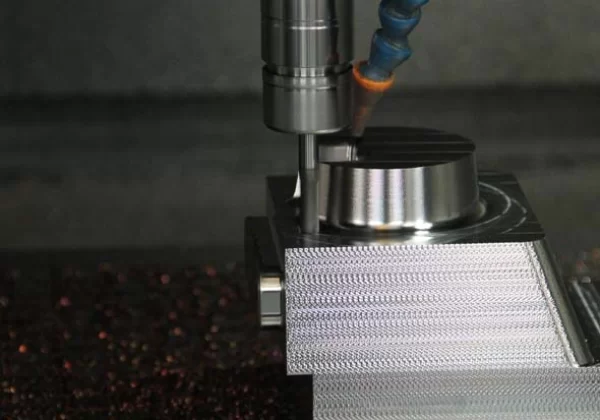

MACHINING CASTINGS SERVICES CAPACITIES

Here, we will introduce our casting Machining service capabilities from surface roughness, technology, materials, machining centers, quality control, and other aspects. Kindly contact our engineers if you want to get more information.

MANUFACTURING: | According To the Drawings Or Samples |

SERVICE METHOD: | OEM |

MATERIALS: | Iron, Aluminum, Steel, Brass, Stainless Steel |

PROCESS: | Turning, Milling, Grinding, Drilling, Reaming, Tapping, Polishing, And So On. |

WEIGHT: | <=2 Tons/piece |

PRODUCTION CAPACITY: | 500 tons/month |

CERTIFICATION: | ISO 9001, IATF 16949 |

TOLERANCE LEVEL: | Min IT5, According to CNC Machining Process. |

SURFACE ROUGHNESS: | RA>=0.2µm |

MACHINING CENTER: | Four-axis, Five-axis, Three-axis. |

MOQ: | 500KG / A Standard Tray |

MACHINING CASTINGS INTRODUCTION

Here, we will introduce the content of metal casting processing, what is casting processing, and the types and functions of mechanical processing. Also explained are the benefits of choosing our finish metal fabrication services. You can contact our engineers or browse our Bolg.

Why Choose Machining Service From HULK Metal

To provide excellent metal casting services, we continuously improve our capabilities from the following four aspects to provide excellent metal casting services. We will accompany you to grow continually and become the best in our respective industries.

-

Factory

HULK Metal has milling machines, mold machines, drilling machines, lathes, CNC machining centers, wire-cutting machines, spark machines, and other mold manufacturing equipment. We can produce molds with a precision of 0.001mm and higher complexity. We have made molds for use on 4500-ton die-casting machines, wax molds for use on wax press machines, and molds for mechanical sand-casting machines. You can contact us to visit factory.

-

Experience

As of today, we have provided mold manufacturing services and high-quality metal casting services for more than 20 industries, including automobiles, textile machinery, food machinery, mining machinery, agricultural machinery, home appliances, furniture, and other manufacturing and construction industries. We cannot disclose the information of customers we have served, but we can develop free solutions according to your requirements. If you are satisfied, we will cooperate again.

-

Quality

Our quality control center has inspection tools such as calipers, calibration meters, bore gauge detectors, depth micrometers, and 3D scanners, as well as experienced quality inspectors and strict quality inspection processes. We can develop a complete quality inspection plan according to your requirements. We have been recognized by hundreds of factories. You can contact us with confidence.

-

Service

Metal casting mold making is just one part of our supply chain. We have successfully integrated and split the supply chain to meet the various needs of our customers. We can provide raw material procurement, mold making, metal casting, quality inspection, customized packaging, freight consulting, and other services. If you require metal casting services, kindly contact us. Our engineers will provide solutions for free and at a premium price.

MACHINING PROCESSES OF YOUR CASTINGS

Here, we mainly talk about the production process of your metal casting mold. The mold is a very important tool in metal casting because it affects the shape and size of the casting. If you want to know more about mold manufacturing, you can contact our engineers.

-

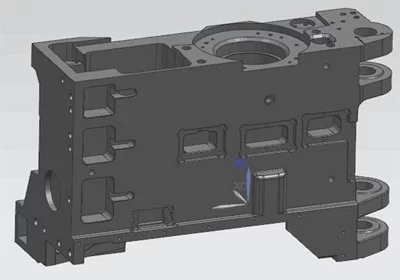

01Castings Leave Machining Allowance

01Castings Leave Machining AllowanceWe need to determine the metal castings that need to be processed machining allowance to save more materials while completing the processing, reduce the number of tool passes, save costs, and improve processing efficiency.

-

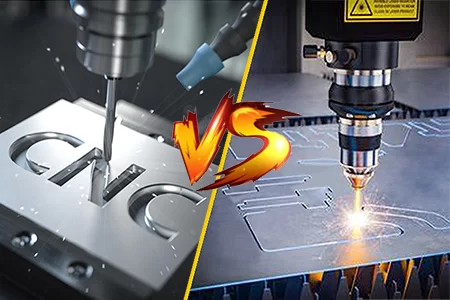

02Choose the Right Machine Tool

02Choose the Right Machine ToolWhether to use a general machine or a CNC machine tool depends on the complexity of the metal castings, which type of additional machine has higher processing efficiency, lower labor costs, and other factors. For specific information, kindly contact our engineers.

-

03Formulate Machining Routes

03Formulate Machining RoutesThe machining of metal castings requires determining the processing sequence. This is very important. A reasonable process will improve processing efficiency and reduce labor costs. Due to space reasons, it will not be described in detail here. You can go to the Blog to learn more.

-

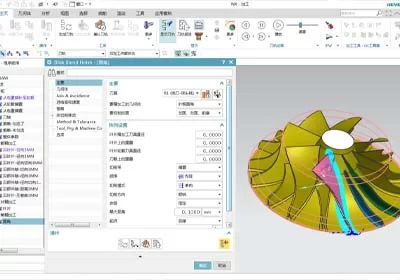

04Design Machining program

04Design Machining programComplete programming according to casting drawings. If it is a general machine tool, the sequence of machining processes needs to be formulated.

-

05Fixing Castings

05Fixing CastingsDetermine how to fix the castings. Reasonable arrangement of fixing methods can reduce the number of casting adjustments and improve processing efficiency.

-

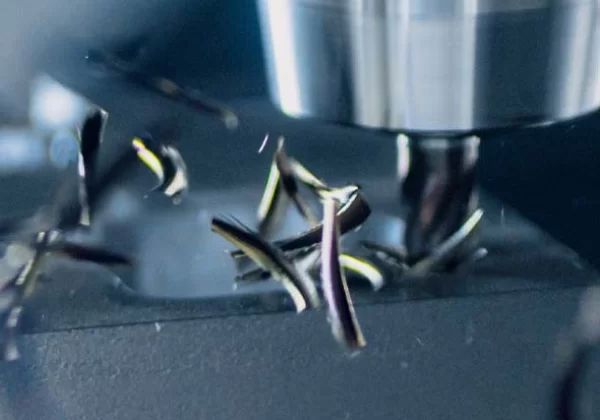

06Machining

06MachiningUse the appropriate tool to start machining the casting according to the set procedures and steps. Pay attention to protection during processing.

-

07Quality Control

07Quality ControlNeed texting The completed castings in multiple dimensions, such as shape and size, to ensure that the finished product fully meets the requirements.

-

08After Service

08After ServiceWe have a comprehensive service team to enable faster delivery of metal castings after production. We also have many free value-added services. Kindly contact our business manager to learn more.