A professional technical team, an excellent lost foam casting factory, and a complete supply chain have laid a solid foundation for providing outstanding metal parts OEM services. Our engineers can develop perfect solutions and better quotations according

Excellent Lost Foam Casting Factory

HULK Metal Lost Foam Casting Foundry

-

Introduction

-

Equipment

-

QC Center

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

Excellent lost foam foundries can often provide technical support, plan more reasonable production solutions based on drawings and order requirements, and complete the agreed quantity and quality of goods within the required delivery period. We also have an advanced quality control center to test the performance of our products and issue strict quality inspection reports. Our freight consulting team can find a more suitable freight company to deliver your order faster. Perfect after-sales service will handle order quality and quantity properly and promptly, as with other issues.

LOST FOAM CASTING FOUNDRY PRODUCTION LINE

Our lost foam foundry is equipped with advanced large-scale three-dimensional vibrating tables, special sandboxes, fully automatic wire cutting machines, foaming machines, induction metal melting furnaces, fully automatic pouring machines, and other equipment. It can ensure the consistency of parts, improve the parts qualification rate, and complete the production of orders faster.

QUALITY CONTROL CENTER

Our quality control center has advanced three-dimensional coordinate testing, hardness tester, impact testing machine, spectrometer, salt spray tester, tensile testing machine, and other testing equipment. Kindly contact our sales manager if you want to visit our factory. They will take you to visit them online or in person.

-

CMM

It can more accurately measure the shape and size of lost foam castings.

-

Electron Microscope

Detect the internal structure and pore distribution of lost foam castings clearly to see if they meet the casting requirements.

-

Hardness Tester

Has Brinell and Rockwell hardness testers. Meet various requirements for hardness measurement.

-

Impact Tester

It is used to measure the resistance of lost foam castings to high-speed loads under different environmental conditions.

-

Salt Spray Test Machine

Place the casting in a simulated environment to test its oxidation resistance, corrosion resistance, etc.

-

Spectrograph

Detect the types and contents of elements in castings.

-

Tensile Testing Machine

Complete various tests such as tension, compression, bending, shearing, peeling, tearing, and two-point extension of lost foam castings.

PROCESS OF LOST FOAM CASTING FOUNDRY COMPLETE YOUR ORDER

HULK Metal will complete your order through the following process. Due to space issues, we cannot introduce them in detail. If you want to know more, you can contact our engineers. They will help you figure out a suitable solution and price for free.

-

PART 01Custom A Suitable Solution

PART 01Custom A Suitable SolutionWe will develop a complete production solution from the very beginning and strive to complete customer orders faster at less cost. The solution content will include delivery time, method, price, product production process, packaging, etc.

-

PART 02Make Samples

PART 02Make SamplesWe will use the following process to pre-make samples and conduct all-round testing. We will send samples for you to test and then start mass production of your order after approval.

-

PART 03Order Scheduling

PART 03Order SchedulingBecause the order quantity is large, the lead time will be longer. However, we will allocate production resources to effectively shorten the lead time of orders by reasonably arranging order processes such as raw material procurement, Model production, Mold production, metal smelting, pouring, cooling, heat treatment, and other processes.

-

PART 04Model Making

PART 04Model MakingThere are two ways to make the model used in lost foam casting: cutting ready-made foam plastic and using foam particles to foam the model in the mold. Appropriate model-making needs to be selected according to the specific requirements of the casting.

-

PART 05Coat Refractory Material

PART 05Coat Refractory MaterialSpray a specific thickness of refractory material on the model. The coating can protect the foam model to prevent metal from penetrating the sand or adhering to the sand and can also reduce the surface roughness of the casting.

-

PART 06Sand Mold Making

PART 06Sand Mold MakingPlace the special sandbox on a three-dimensional vibrating table, pour in the bottom sand, shake, and spread it evenly. Finally, put in the model coated with refractory material, continue filling with sand, and vibrate. Attach the membrane so that it is under negative pressure.

-

PART 07Metal Smelting

PART 07Metal SmeltingThe metal smelting process is very complicated and will not be described in detail here. If you have castings that need manufacturing, kindly contact our sales managers. They will give you a complete solution.

-

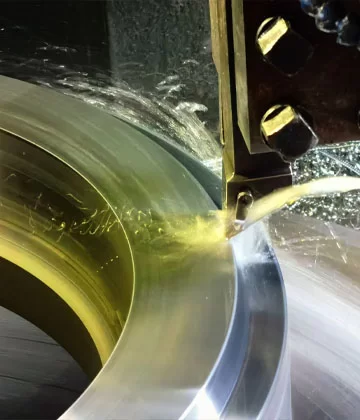

PART 08Pouring & Cooling

PART 08Pouring & CoolingLost foam casting can also be divided into pressure, vacuum low pressure, vibration, and other casting processes. The pouring speed and process vary greatly depending on the process.

-

PART 09Finishing

PART 09FinishingThe cooled castings undergo sand shakeout and other cleaning processes before being polished, machined, and physically and chemically surface treated as required. This gives you the finished product.

-

PART 10Packaging & Warehousing

PART 10Packaging & WarehousingDesign exquisite packaging according to needs and provide a variety of packaging materials to give customers more options. Strictly managed warehouses can better preserve goods.

-

PART 11Delivery and After Service

PART 11Delivery and After ServiceWe have a freight consultation center that can help customers screen freight and logistics companies. Find better shipping options for faster delivery. After-sales service ensures the quality and quantity of goods and provides other free value-added services.

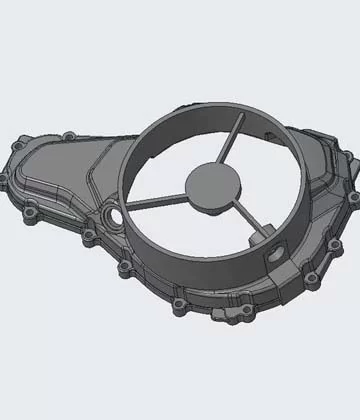

PARTS HULK METAL LOST FOAM CASTING FOUNDRY

We have produced large marine castings, mining machinery castings, engineering machinery castings, valve accessories, pump bodies, reducer cases, etc. Kindly contact our sales manager if you are looking for a lost foam foundry. He will lead a team to develop perfect solutions, calculate prices, and provide perfect services.

More Results

CHOOSING HULK METAL AS OEM FOUNDRY YOU WILL GET

HULK Metal will complete the delivery of all orders faster and at lower costs through a complete supply chain, allowing each customer to receive goods with guaranteed quality and quantity faster and provide customers with an easier purchasing experience with complete services.

-

Get Higher Quality Castings

ISO 9001-certified factories, strict production processes, experienced teams, and advanced processing equipment are the basis for our ability to deliver high-quality goods. Advanced testing equipment and strict procedures are the guarantee that we can complete orders with high quality. Kindly contact our sales manager. They will take you to visit our factory.

-

Get Goods Faster

Lead time can be effectively shortened by rationally arranging the production process. Its own logistics team can transport goods to designated ports faster. A professional freight consulting team connects you to the right freight company faster. We can achieve seamless transfer of goods to achieve faster delivery of goods.

-

Spend Less Money

When costs are controlled from each process of a complete supply chain, substantial cost savings can be achieved without affecting quality. Purchasing in larger quantities allows our supply chain to run efficiently for longer, resulting in greater cost savings. This means you spend less money to complete the order.

-

Spend Less Time & Energy

We will have a team formed of technology, procurement, production, quality inspection, freight consulting, procurement, and after-sales personnel to provide you with one-to-one service. Develop more suitable solutions and quotes based on your requirements. We provide lifelong services to help you solve various problems during the purchasing process.

ARTICLES OF LOST FOAM CASTING FOUNDRY

We have compiled the content of the lost foam casting foundry. You can more fully understand the process of lost foam casting, the parts that can be processed, and how the foundry produces your products. You can also contact our sales manager directly and send us drawings to get more suitable solutions and quotations.