HULK Metal has 20 years of casting experience and can complete the production, quality inspection, packaging, freight and after-sales of orders according to plowshare for agriculture machinery drawings. Our monthly output can reach 400 tons/month. Kindly

HULK Metal Supply Better

Plowshare for Agriculture Machinery OEM Service

-

Features

-

Capacities

-

Description

-

Factories visit

-

Benefits

-

Articles

-

Review

-

Top

It is one of the most necessary tools in agricultural planting. Its function is to turn over a certain thickness of land, loosen the soil, oxygenate the ground, cover weeds, and decompose them. A large scarifier combines multiple plowshares on one device and uses a tractor as power to complete more extensive operations. Plowshare is a worn part, and the wear is more serious when working on poor soil, so it needs to be replaced regularly. It is cast from wear-resistant iron (or, at a higher cost, wear-resistant steel). It will come in different shapes and sizes depending on the function of the scarifier. We are more familiar with which casting process can be used to complete its production at a lower cost. If you want to know more, kindly contact our engineers.

PLOWSHARE FOR AGRICULTURE MACHINERY WE CAN PRODUCE

Here, we will introduce our OEM capabilities in terms of production methods, materials, process types, production capacity, quality control, etc. Contact us now for a complete solution that is more suitable for you and a great price.

Manufacturing Method | OEM |

Material | Iron / Steel According to Drawings |

Casting Process | Sand Casting / Heat Treatment |

Certification | ISO9001 / According to Requirements |

Production Capacity | 500 Tons/Month |

Finishing | Machining / Powder Coating |

QC | Hardness / Wear Resistance / Tolerance / According to Requirements |

HOW HULK METAL CAST YOUR PLOWSHARE FOR AGRICULTURE MACHINERY

Develop a Casting Solution:

After receiving the demand, we will communicate with you for more information. During this process, you may need to provide plowshare drawings, samples, required quantity, delivery date, delivery method, and other information. Our engineers use this information to develop a complete casting solution and calculate a price that satisfies you.

Make the Mold:

We will determine whether to use manual molding or mechanical molding based on the order quantity (artificial molding is less efficient, but the cost is also relatively low and is suitable for small orders; automatic molding is more expensive, has higher production efficiency, and is suited for larger orders), and Use this to design and make molds.

Make Samples:

We will make samples and send them to you for testing. Start mass production after making sure that all aspects can meet your requirements.

Mass Production:

This is a brief introduction to the production process of your order. Kindly contact our sales manager to take you to visit Plowshare's casting factory online or on-site.

Manufacturing The Casting Mold:

This step is more complicated and involves the selection of sand, binder, modeling method, etc. You can contact our engineers or read our related articles to know more about it.

Metal Smelting & Pouring:

Smelt the metal according to the materials of Plowshare and poured the smelted liquid metal into the mold along the pouring port.

Cooling & Cleaning:

After the casting is cooled, it needs to be cut to remove the excess part and then shot blasted to remove impurities on the surface.

Heat Treatment:

Place the casting in a heat treatment furnace, and after treatment at a specific temperature and time, the metallographic, stress distribution, and mechanical properties can be obtained to meet the requirements.

Finishing:

Use mechanical processing to finish surface roughness, holes, threads, etc. Do surface treatment, such as powder spraying. This completes the processing of the order.

Packaging:

We provide wooden boxes, cartons, and other packaging methods. We also supply packaging printing services. You can enhance the strength of your brand by putting your company message on the box.

Delivery:

We have a freight consultation center to find a more suitable freight company and provide a variety of transportation options for you to choose from. This is an essential ring in our supply chain and can bring you more convenience.

After-sales Service:

We provide after-sales service after the completion of delivery to help you solve various problems with the product. Kindly provide feedback on our services. This will enable us to provide you with higher services.

Here, we will introduce our sand casting factory, machining factory, and quality control center that produces the plowshare for agriculture machinery. If you want to know more, Kindly click on them or contact our engineers to visit the factory online or on-site.

Sand Casting Factory

Machining Factory

QC Center

-

Sand Casting Factory

We will first determine which sand casting process to use based on Plowshare's material, shape (generally not very complicated), performance, and other requirements. Using more appropriate processes can improve order yield, reduce production steps, reduce order costs, and shorten order time. Larger orders can lower this cost throughout the process, and we share the revenue with you. Our Sand Casting Factory has advanced equipment and passed ISO9001 certification. Kindly Contact us with confidence. Our engineers will develop a complete solution based on the drawings or samples and calculate a great price.

-

Machining Factory

Plowshare may need to undergo some processing after casting, such as cutting, drilling, and other processes, before it can be formed completely. For Plowshares with simple shapes and low processing difficulty, we will choose general-purpose machine tools that can improve processing efficiency and save time and capital costs. Our engineers will determine the required processing method based on the drawings and send trial samples to customers. After passing the test, mass production will begin. Kindly click to learn more about our machining factory or contact our engineers for free solutions and quotations.

-

QC Center

Plowshare mainly tests two properties, wear resistance and hardness, as well as parameters such as shape and size. Our quality control center is equipped with hardness testers, stamping testing machines, and other testing instruments that can complete various performance tests according to requirements. We support customized testing services. Kindly contact us for details.

BENEFITS CHOOSE HULK METAL AS YOUR PLOWSHARE OEM FACTORY.

By choosing us as your OEM factory, your Plowshare can be completed faster and at a lower price with guaranteed quality and quantity. We will also provide comprehensive services to protect you. Kindly contact our engineers to learn more.

-

Shorter Lead Time

A shorter lead time can save more time costs, leaving you with more free time to make decisions on other things. Therefore, we will reasonably arrange the order production process according to customer requirements. Production shutdowns due to material shortages can be avoided by obtaining sufficient materials faster. Strict factory management, advanced production equipment, quality inspection instruments, and experienced worker teams can improve plowshare's yield rate.

-

Higher Quality

We believe that quality is the most important indicator of a product, so we will spare no effort to improve the quality of every order. ISO 9001-certified foundry with stricter quality management processes. Optimize the casting process and improve the performance of castings. The quality control center will strictly test the performance and indicators of raw materials, semi-finished products, and finished products. This will make your plowshare orders of higher quality.

-

Excellent Service

We believe excellent service can make the customer's purchasing process easier, leaving more energy to deal with other matters. Therefore, we continue to integrate the supply chain to redefine services. This allows us to have a unified "customer satisfaction" service standard from raw material procurement to after-sales when completing customer orders. When you place your plowshare order with us for production, you will know what "worry-free" means because we will inform you of the order information regularly.

-

Cheaper

We believe that cheapness should be based on high quality, so whether it is solution formulation, production, quality inspection, packaging, etc., we will take your quality requirements as the premise and then control costs through various methods. The larger the quantity of each plowshare, the lower the order cost and the lower the price. Kindly contact our engineers. He will communicate the details with you and develop a complete solution and a more advantageous price according to your requirements.

OTHER CONTENT YOU MAY BE INTERESTED IN

Curious to learn more? We've got other insightful content related to metal casting that you won't want to miss—covering techniques, material selection, and real-world applications. Dive deeper and discover how quality casting makes all the difference!

-

April 09, 2025

Why Choose Hulk Metal to Customize Your Plowshare for Agriculture Machinery?

READ MORE

-

April 01, 2025

What Factors Should Be Considered When Choosing A Metal Casting Method?

READ MORE

-

March 28, 2025

Everything You Need to Know About Die Casting!

READ MORE

-

March 26, 2025

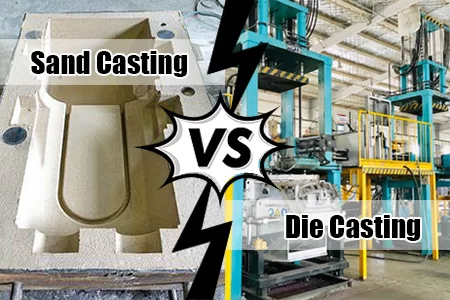

Sand Casting vs. Die Casting: Which is Right for Your Project?

READ MORE

-

March 25, 2025

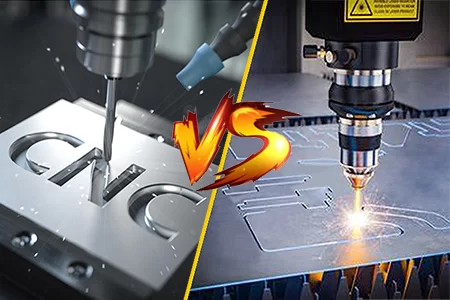

CNC Cutting vs. Laser Cutting: Which One is Right for Your Project?

READ MORE

-

March 12, 2025

Applications of Stainless Steel Castings in Medical Devices

READ MORE

-

March 03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE