Why Choose Hulk Metal to Customize Your Plowshare for Agriculture Machinery?

-

Home>

-

Blog>

-

Technology>

Why Choose Hulk Metal to Customize Your Plowshare for Agriculture Machinery?

In the world of modern farming, efficiency and durability are everything. Agricultural machinery works in some of the harshest environments—hard soil, rocks, moisture, and constant wear and tear. That’s why every component matters, especially the plowshare, which takes the brunt of the impact during tillage operations.

At Hulk Metal, we specialize in custom metal casting solutions for agriculture, and one of our most in-demand products is the customized plowshare. In this blog, we’ll break down why partnering with Hulk Metal for your plowshare needs is a smart move—and how we can help extend the life and performance of your farming equipment.

Tailored to Fit Your Machine and Working Conditions

No two fields are the same, and neither are two plowshares. We understand that different soil types and machinery models require different designs and materials. At Hulk Metal, we customize plowshares based on your unique specifications, including:

Machine model and size

Working depth and width

Soil type and abrasion level

Desired hardness and toughness

All you need to do is send us your drawing or sample, and our engineers will work with you to optimize the geometry and performance of your plowshare.

Advanced Metal Casting Capabilities

Hulk Metal has over a decade of experience in precision metal casting, using both sand casting and investment casting methods. Our expertise allows us to produce plowshares with:

High dimensional accuracy

Smooth surface finish

Consistent hardness and wear resistance

We use ductile iron, high manganese steel, and wear-resistant alloys—materials carefully selected to survive the rigors of heavy-duty agricultural work.

Superior Wear Resistance for Longer Lifespan

Our cast plowshares are designed to reduce your replacement frequency and overall maintenance costs. By using high-performance materials and heat treatment techniques, we offer plowshares that resist cracking, chipping, and rapid wear—even in rocky or abrasive soils.

In short, you get more working hours per blade, which means more productivity and fewer interruptions during planting or tilling seasons.

Strict Quality Control & ISO-Certified Production

We know how important consistency and reliability are in farming operations. That’s why our production process is backed by ISO 9001 certification and a full range of testing procedures, including:

Chemical composition analysis

Hardness and tensile strength testing

Dimensional inspection

Surface quality checks

Every batch of plowshares is traceable, inspected, and accompanied by detailed quality reports to give you peace of mind.

Fast Lead Time and Global Shipping Support

We don’t just stop at production. Our logistics team ensures quick and reliable delivery of your orders—whether you're in North America, Europe, or Southeast Asia. We work with experienced freight partners to reduce shipping delays and ensure your parts arrive safely and on time.

One-on-One Engineering Support

When you choose Hulk Metal, you don’t just get a product—you get a partner. Our engineering team offers hands-on support, from initial design consultation to post-delivery performance feedback. Whether you're looking to improve soil penetration, reduce drag, or test a new alloy, we’re here to help.

Ready to Customize Your Agricultural Plowshare?

Choosing the right supplier for your agricultural components can make a huge difference in performance and profitability. At Hulk Metal, we combine engineering expertise, advanced casting technology, and customer-first service to deliver custom plowshares that work as hard as you do.

Contact us today to get a free consultation or submit your plowshare drawings. Let's build something that lasts—together.

Article Navigation

Article Navigation

Industries

Foundries

-

March.28, 2025

Everything You Need to Know About Die Casting!

READ MORE

-

March.26, 2025

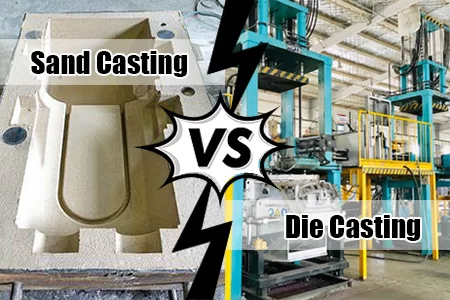

Sand Casting vs. Die Casting: Which is Right for Your Project?

READ MORE

-

March.12, 2025

Applications of Stainless Steel Castings in Medical Devices

READ MORE

-

March.03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE

-

February.25, 2025

How to Compare Product Quality Between Different Casting Foundries?

READ MORE

-

February.14, 2025

What Are The Metal Casting Materials Commonly Used in Foundries?

READ MORE