HULK Metal can use resin, water glass, coating and other sand casting processes to complete ductile iron parts. Please contact us for a quote and solution.

HULK Metal Supply Better

Ductile Iron Sand Casting OEM Service

-

Capacities

-

Processes

-

Parts

-

Other Types

-

Foundry

-

Benefits

-

Introduction

-

Articles

-

Review

-

Top

DUCTILE IRON SAND CASTING CAPACITIES

Here is a demonstration of our capabilities in casting ductile iron parts. We will introduce it from the service method, sand casting process, ductile iron grade, unit weight, monthly output, finishing method, minimum order quantity, etc. Kindly contact our engineers to discuss details. Large orders also get better prices.

MANUFACTURING: | According To the Drawings Or Samples |

SERVICE METHOD: | OEM |

MATERIALS: | QT400, QT450, QT500, QT600, QT700, QT800, QT900 |

PROCESS: | Clay sand casting(Green sand casting), Water glass sand casting, Resin sand casting, Coated sand casting |

WEIGHT: | <=2 Tons/piece |

PRODUCTION CAPACITY: | 500 tons / month |

CERTIFICATION: | ISO 9001 |

FINISHING: | Heat Treatment, CNC Machining, Surface Treatment |

MOQ: | 500KG / A Standard Tray |

PROCESS OF DUCTILE IRON SAND CASTINGS

Here is our summary of the production process of ductile iron sand castings. In detail, it can be divided into two types: mechanical molding and manual molding. Kindly contact our engineer to take you to visit the factory, and he will explain in detail.

-

01

Mold Making

The mold is made concerning the drawings and according to the machining allowance required for subsequent machining. It is made of many kinds of materials, such as stainless steel, carbon steel, aluminum alloy, etc. To save costs, many factories will also use wood (if only a few dozen pieces are produced, this material is more cost-effective).

-

02

Sample Making

After the mold is made, we will soon produce several samples to test the material and various aspects of performance. This process is our simulation process for mass production. After the sample passes the test, the order will be completed according to this process. This can effectively improve the pass rate of orders and the overall quality of castings, shorten the order production cycle, and reduce costs.

-

03

Batch Production

After the samples pass the test, we will schedule production, purchase raw materials (costs will be saved when in large quantities, so the unit price of large-volume orders will be lower), and production (large-volume orders will also allow our production lines to run for a long time, saving labor and Time costs). Kindly contact our sales manager to update the price and increase the order quantity if you need to.

-

04

Sand Mold and Core Making

The sand core is usually prefabricated and put in when making the sand mold. There are two types of casting mold making: mechanical molding and manual molding. Engineers will choose a more appropriate method based on order volume. Both automatic molding and manual molding require vibrated sand packing. Kindly contact our sales manager to visit the factory. They will explain it to you in detail.

-

05

Consolidate Sandbox

Box closing means buckling the upper and lower sandboxes together to form a cavity with a pouring port on the upper sandbox. The sand core needs to be placed in the designated location before packing. To prevent the sand from collapsing in the cavity when closing the box, the sand needs to be vibrated entirely when making the sandbox.

-

06

Metal Smelting

The process of ductile iron smelting is relatively complicated. During smelting, we add different reagents according to temperature and time. During the smelting process, pre-furnace inspection is required to ensure that the material meets the requirements. Our heating method is electromagnetic heating, which is more environmentally friendly. Kindly contact us to learn more about how your casting materials are smelted.

-

07

Pouring

Adding a spheroidizing agent will lower the temperature of the molten iron, which makes rare earth and magnesium elements form slag inclusions in the firing ladle and pouring system. If these slag inclusions enter the mold cavity, they will cause casting defects such as inclusions, pinholes, and rough casting surfaces. Therefore, special attention is required when pouring. Skilled workers can reduce the occurrence of this situation to a greater extent.

-

08

Cleaning

After the pouring is completed, cooling and sand shakeout are carried out. When the sand shakeout is done, attention should be paid to the dust protection of employees, and dust removal equipment should be used to protect the environment. After the shakeout, the gate is cut and removed to obtain the cast slab. The cast slab is then shot-blasted to make the surface smoother.

-

09

Heat Treatment

Whether to perform heat treatment needs to be determined according to the mechanical property requirements of the casting. The performance of some castings is already up to standard when casting is completed. The primary function of heat treatment is to eliminate the internal stress of the casting, improve the internal structure of the casting, and enhance the mechanical properties. The cost of heat-treated castings will be higher.

-

10

Finishing

The cast billet requires pass machining to adjust the surface roughness, tolerance, and shape according to requirements. The adjusted castings that are basically completed require pass surface treatment according to requirements. The surface treatment methods of ductile iron parts mainly include powder spraying, galvanizing, and passivation. If there is no surface treatment, it will be dipped in anti-rust oil for simple anti-rust treatment.

-

11

Packaging

There are many ways to package, and I won’t go into details here. We provide customization services for the appearance of packaging materials. Kindly contact our sales manager to learn more.

-

12

Delivery & After Service

We support DDP, DDU, DES, DEQ, EXW, and other delivery methods and can ship worldwide. We have professional freight consulting services to help you find a better freight company for free. After completed delivery, we also have an after-sales service to provide excellent support.

DUCTILE IRON PARTS HULK METAL CASTS

Here are the ductile iron castings we have produced using the sand casting process, for example, sewer pipe fittings, valve bodies, agricultural machinery accessories, textile machinery accessories, etc. What we provide is OEM service. Engineers can plan a better solution and convert a better price according to the drawings.

More Results

MORE DUCTILE IRON SAND CASTING SERVICE

Here, we introduce sand-casting services that can process ductile iron. Choosing the appropriate casting process can shorten the order completion time and reduce costs. Kindly contact our engineers if you want to know what casting process the part requires. They will tell you the details.

Water Glass Sand Casting

Resin Sand Casting

Coated Sand Casting

Green Sand Casting

-

Water Glass Sand Casting

Sand casting process using silicate aqueous solution as the binder. Water glass sand casting has high requirements on the castings' size, shape, and surface quality, so it is suitable for casting parts with small volumes, complex structures, and high surface quality requirements. Such as bearings, gears, machine tool parts, automobile parts, and other mechanical parts; plastic molds, rubber molds, die-casting molds, and different molds; doors, windows, stairs, railings, and other building components. Kindly contact our engineers to ask if this process can be used with your order.

-

Resin Sand Casting

Sand casting process using synthetic resin as a binder. It is a casting method widely used by large casting manufacturers. Although the dimensional accuracy of casting is worse than that of coated sand, its cost is lower than that of coated sand, and it is more suitable for large sizes. , complex shapes, high surface quality requirements, precision processing, corrosion resistance, wear resistance, and parts that work at high temperatures.

-

Coated Sand Casting

Coated sand is a sand mold that uses thermoplastic resin as a binder and covers the surface of the sand grains with a resin film. It is suitable for casting various parts with large volumes, complex structures, high surface quality requirements, precision machining, high corrosion resistance, and wear resistance requirements, and work at high temperatures. Kindly send us the drawings. We will plan a more suitable solution according to the drawings and calculate a lower price.

-

Green Sand Casting

Also called clay sand casting, it is a casting process that uses water and clay as binders. Sand molds have high strength and can be used to cast large, thick-walled castings. The surface finish of the casting is high, and no secondary processing is required. Suitable for casting castings of various shapes, sizes, and materials. Kindly contact us if you have mechanical parts, molds, construction metal components, and so on that need sand casting. We will calculate a better price.

VIEW DUCTILE IRON SAND CASTING FOUNDRY

Here, we show why our sand casting factory provides high-quality ductile iron OEM services. We have advanced production equipment, testing instruments, and a team of workers. We strictly implement ISO 9001. It can ensure that every order has an extraordinary pass rate. Kindly contact our engineer, and he will take you to visit the factory online or on-site.

-

Equipment

We have advanced automatic molding lines and professional manual molding lines. We will choose a more suitable process based on the requirements of your order. Ensure on-time delivery while improving the overall quality of orders and reducing costs.

-

Production Team

Complete quality inspection instruments can detect the material, metallography, hardness, corrosion resistance, and various mechanical properties of ductile iron castings. We can issue material and product reports upon request.

-

QC Center

They are our treasures because they can skillfully operate and maintain the equipment to ensure that orders are completed on time with quality and quantity.

BENEFITS YOU WILL GET WHEN YOU CHOOSE HULK METAL.

We have integrated a complete supply chain to provide excellent service. Now, we have an experienced technical team, an ISO 9001-certified factory, a professional freight consulting team, a rigorous quality inspection team, and an excellent service team. You receive higher quality goods faster at lower prices and enjoy superior service when you link up with our supply chain.

-

Shorter Lead Time

We will find and solve potential problems in order production in the early stage of design, optimize the casting process according to requirements to improve process efficiency and use our familiarity with various sand casting processes combined with the requirements of ductile iron castings to select a more suitable process to complete the order. We will use this to calculate the price and develop a perfect solution. Improving the supply chain will lead to higher efficiency under unified coordination.

-

Higher Quality

The professional technical team will use advanced software to measure the dimensions of the casting, determine the machining allowance to make the mold and select the correct casting process to complete your ductile iron casting. We can buy higher quality materials. Advanced technology and strict testing can improve the overall quality of your order.

-

Excellent Service

A complete supply chain enables us to provide excellent services. The sales and technical teams will promptly respond to your inquiries and provide accurate and timely pricing, delivery times, and other information. They will also help you solve various problems quickly. We will provide timely feedback on the order production progress so that you can effectively control it. We also supply professional freight consulting and after-sales services.

-

Better Prices

We will reduce costs by integrating the supply chain without affecting order quality. Horizontal integration increases the types of sand castings and vertically increases service content to control costs in an all-around way. Our technical team will develop more suitable solutions based on drawings and customer requirements to reduce the price to the greatest extent. Kindly contact us for a detailed quote.

DUCTILE IRON INTRODUCTION

Here, we will introduce you to some basic information about ductile iron, the advantages, and applications of ductile iron sand castings, etc. We have extensive experience in ductile iron sand casting. Kindly contact us for a quote if you have parts that need to be produced using ductile iron.

-

Ductile Iron & Sand Casting

Ductile iron is a kind of cast iron with internal graphite crystals in spherical structures. Ductile iron far exceeds gray cast iron and is very close to ordinary steel in terms of strength, plasticity, and toughness. It has many names, such as ductile cast iron, nodular cast iron, and spheroidal graphite iron. Its cutting surface is gray, its luster is brighter than gray iron, and its surface roughness is similar to gray iron. Ductile iron parts with low surface accuracy requirements, relatively simple structure, and small volume can be sand cast, such as sewer pipe fittings, structural pipe fittings, etc. Lost foam casting can be used for larger volumes and complex structures, such as valve bodies, reducer casings, pump bodies, etc.

-

Ductile Iron Grade

Ductile iron is graded according to its tensile strength and yield strength. The most common grades are ASTM A536 Grade 60-40-18, Grade 65-45-12, Grade 80-55-06, and Grade 100-70-03. The first two digits of the grade number indicate the minimum tensile strength in ksi, and the third two digits indicate the minimum yield strength in ksi. The last two digits indicate the minimum elongation in 2 inches.

Application:

60-40-18: General-purpose, such as pipe and fittings, machine tools, and pumps

65-45-12: Requiring Higher Strength and Ductility, such as automotive components and wind turbines

80-55-06: Requiring High Strength and Fatigue Resistance, such as crankshafts and camshafts

100-70-03: Requiring the Highest Strength and Wear Resistance, such as mining equipment and construction equipment

If you happen to want to customize ductile iron sand castings, please click the button below to contact us and we will give you the best solution and quotation.

ARTICLE OF DUCTILE IRON SAND CASTING

Here, you can see our collection of articles about ductile iron sand casting, including a comparison table of ductile iron grades. A detailed introduction to the sand casting process, common problems and solutions for ductile iron sand castings, etc. Kindly contact our engineers for solutions and quotes if you have parts that need to be produced using ductile iron.

-

April 09, 2025

Why Choose Hulk Metal to Customize Your Plowshare for Agriculture Machinery?

READ MORE

-

March 26, 2025

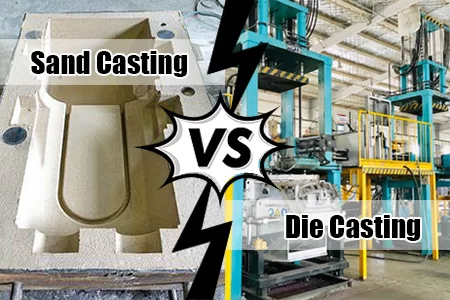

Sand Casting vs. Die Casting: Which is Right for Your Project?

READ MORE

-

March 18, 2025

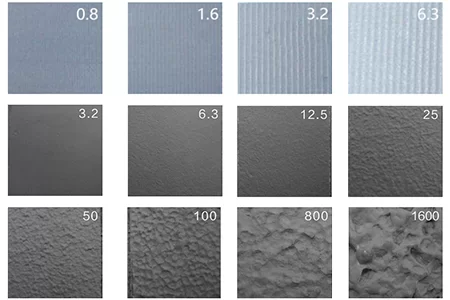

Surface Roughness Comparison of Castings with Different Materials and Processes

READ MORE

-

March 10, 2025

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

READ MORE

-

March 03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE