By choosing the right sand casting process, you can effectively improve efficiency and reduce costs. Kindly contact us to get a more suitable solution and the latest quotation.

As A Top Sand Casting Company HULK Metal Supplies

Better Gray Iron Sand Casting Service

-

Capacities

-

Processes

-

Parts

-

Other Types

-

Foundry

-

Benefits

-

Introduction

-

Articles

-

Review

-

Top

GRAY IRON SAND CASTING CAPACITIES

Here, we list the gray iron grades and sand casting processes we have processed for customers. The perfect supply chain allows us to provide comprehensive production services to make the whole process more efficient, quality and cost more controllable. Contact us now to get a better price.

MANUFACTURING: | According To the Drawings Or Samples |

SERVICE METHOD: | OEM |

MATERIALS: | HT100, HT150, HT200, HT250, HT300, HT350 |

PROCESS: | Clay Sand Casting (Green Sand Casting), Water Glass Sand Casting, Resin Sand Casting, Coated Sand Casting |

WEIGHT: | <=2 Tons/piece |

PRODUCTION CAPACITY: | 500 tons / month |

CERTIFICATION: | ISO 9001 |

FINISHING: | Heat Treatment, CNC Machining, Surface Treatment |

MOQ: | 500KG / A Standard Tray |

PROCESS OF GRAY IRON SAND CASTINGS

When your order starts mass production, it will proceed in the following process. It is summarized as mold making, gray iron smelting, pouring, cooling, cleaning, heat treatment, finishing, surface treatment, packaging, delivery, after-sales service. Kindly contact our sales manager, they will take you to visit the factory and explain in detail.

-

01

Mold Making

The production of casting molds is divided into three parts. First, we need to make a model according to the drawing of the part. This model needs to leave enough processing allowance (if necessary). Secondly, make sand cores and sand molds. Finally, place the sand core in a specific position of the sand mold and close the mold to complete the production of the casting.

-

02

Gray Iron Smelting

During the gray iron smelting process, attention should be paid to the mass fraction of carbon and silicon elements. Too high or too low will reduce the performance of gray iron. Gray iron is divided into pearlite gray iron, ferrite gray iron, pearlite-ferrite gray iron and inoculated cast iron according to its internal structure, and the smelting methods are different.

-

03

Pouring

The smelted gray iron needs to be poured into the mold cavity along the pouring gate at a specific temperature and speed. If the temperature is too low, oxide scale will be generated on the surface, and if it is poured into the casting, it will cause a defective casting. If the speed is too fast, the air in the mold cavity cannot be discharged in time, resulting in defective products. This will reduce production efficiency.

-

04

Cooling

The cooling rate of the casting has a great influence on the graphite morphology and distribution, and the matrix structure. Reasonable control of the cooling rate of the casting can control the performance of the gray iron casting. The cooling rate can be increased by optimizing the pouring and cooling system.

-

05

Cleaning

After the casting is fully cooled, it needs to be sanded, cut, and shot blasted to obtain a casting. Most of the sand in the sand casting process can be recycled to reduce costs.

-

06

Heat Treatment

Common heat treatment methods for gray iron castings include stress relief annealing to prevent deformation and cracks in castings, graphitization annealing to eliminate white structure, reduce hardness and improve cutting performance, and surface quenching to increase surface hardness and extend service life.

-

07

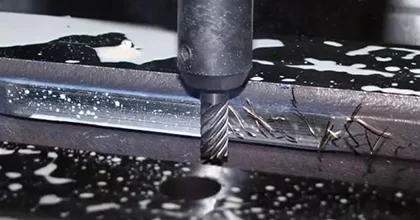

Finishing

Use machining to complete the processing of casting surface, interior, holes and tooth surface. The main processing methods are turning, milling, grinding, reaming, drilling and tapping.

-

08

Surface Treatment

Physical surface treatment includes polishing, brushing, sandblasting, hot dip plating, powder coating, etc. Chemical surface treatment includes electrophoresis, passivation, etc. Our supply chain can meet most of your surface treatment requirements.

-

09

Packaging

We support services like packaging materials, appearance design, printing, etc. You can contact our sales manager to inquire about the details.

-

10

Delivery

We support DDP, DDU, DES, DEQ, EXW and other delivery methods, and can ship worldwide. We have professional freight consulting services and can help you find a better freight company for free.

-

11

After Service

We will ensure various problems after the delivery of goods through high-quality after-sales service. And help you build a personal demand library such as warehouse management from HULK Metal to provide more personalized services.

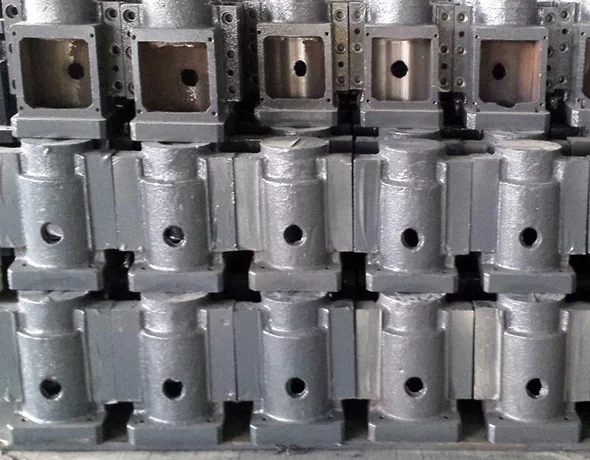

GRAY IRON PARTS HULK METAL CASTS

Here, we will show some parts cast with gray iron. Sand casting is suitable for producing almost all gray iron parts, but factors such as efficiency and cost need to be considered. Therefore, finding a professional foundry to plan solutions according to the drawings can effectively reduce costs and shorten lead time.

More Results

MORE GRAY IRON SAND CASTING SERVICE

Here, we have sorted out several processes that can be used for sand casting gray iron according to the binder. The main introduction is which gray iron parts these casting methods are suitable for casting. Kindly contact our engineers to get solutions and quotes if you have gray iron parts that need to be cast.

Water Glass Sand Casting

Resin Sand Casting

Coated Sand Casting

Green Sand Casting

-

Water Glass Sand Casting

Use water glass sand casting to produce gray iron castings with relatively high surface accuracy requirements, short delivery cycle, and small and medium batches. We often use it to produce automobile engine cylinders, crankcases, exhaust manifolds, mechanical pump bodies, pump shells, valve bodies, transmission parts, engineering machinery parts, building structure connectors, etc. Whether your product is suitable for water glass casting needs to be determined according to specific drawings and requirements. Kindly contact our engineers for details.

-

Resin Sand Casting

Resin sand casting process can be divided into thermosetting sand casting, self-hardening sand casting and gas-solidified sand casting according to the solidification of resin. Resin sand process can shorten the entire production process (reducing part of the mechanical processing process). We will use resin sand casting to produce gray iron castings with high dimensional accuracy and surface accuracy and mass production. Similarly, you can send us the drawings and our engineers will plan a more suitable solution and a better quotation.

-

Coated Sand Casting

Coated sand casting mainly uses natural quartz sand as raw material and thermoplastic phenolic resin, hexamethylenetetramine and reinforcing agent as raw materials. The ratio is adjusted according to the requirements of the casting. Coated sand casting is one of the best casting methods for automobile, tractor, hydraulic press and other parts. However, due to its complex process, more expensive materials and longer production cycle, it is generally only used to produce small batches of high-precision and complex-shaped orders.

-

Green Sand Casting

Green sand casting, also called clay sand casting, is the most common casting method. It has low production cost and simple process, suitable for large, medium and small orders. It is suitable for producing castings with simple geometry, relatively poor surface quality, low precision and low cost, such as structural pipes, engine blocks, sewer pipes, etc. You can contact our engineers to consult whether the order is suitable for production using green sand casting.

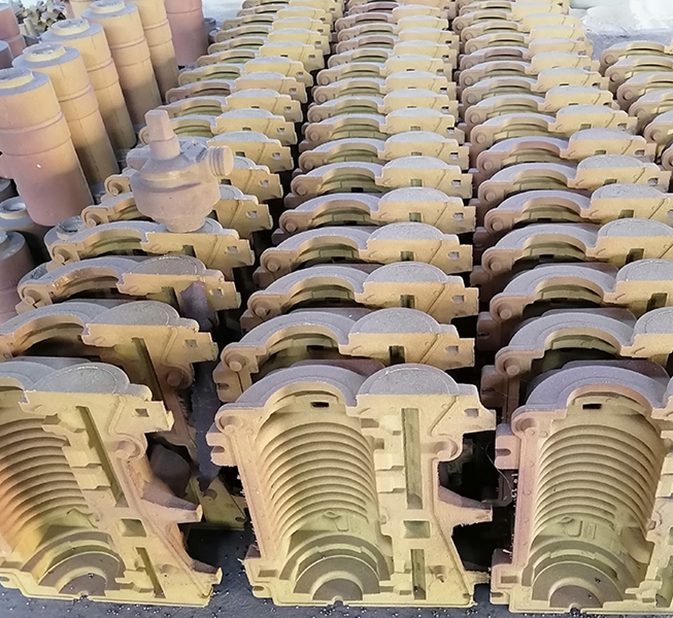

VISIT GRAY IRON SAND CASTING FOUNDRY

Visit our foundry to learn about our production and service capabilities before deciding whether to place an order with us. Kindly contact our sales manager. He will take you on an online or offline tour of the factory and explain in detail.

-

Equipment

We have professional molding, pouring, heat treatment, sand dropping, cutting, and shot blasting equipment, as well as advanced machining centers and surface treatment workshops. We can complete each of your orders more efficiently and with high quality.

-

QC Center

The quality control center is equipped with advanced testing instruments to achieve precise measurements of surface accuracy, shape, tolerance, mechanical properties and chemical properties.

-

Production Team

Experienced technical, production, quality inspection, freight consulting and after-sales service team members can ensure better service.

BENEFITS YOU WILL GET FROM HULK METAL.

At HULK Metal, you will benefit from delivery speed, quality, price, service, etc. We briefly describe the process and reasons below. Kindly contact our sales manager to experience them.

-

Gets Goods Faster

Reasonable planning of the production process shortens the overall order time. Advanced production equipment makes the entire process more efficient, strict management ensures that each process can be carried out in an orderly manner, and experienced workers can better maintain and use equipment to complete the production of orders. The professional freight consulting team can find a more suitable freight company to complete the transportation and delivery of goods more timely and faster.

-

Higher Quality

Rigorous production processes, production management, and testing processes make quality traceable and controllable, improving the quality of order finishing.

Advanced testing instruments can complete all-round testing of castings and issue complete material and product testing reports. -

Save Time & Energy

We help customers save more time and energy through perfect services. The vertically integrated supply chain allows us to provide packaging, warehousing, freight and after-sales services in addition to production. We can improve the overall service quality of the supply chain and integrate all services together. Customers can enjoy unified high-quality services to save time and energy in all aspects.

-

Better Prices

Our three-dimensional supply chain can better coordinate and plan various resources and control the cost of each aspect of the order to the minimum. We will complete the planning of the overall solution and calculate a price that satisfies customers while ensuring product quality. Kindly contact our sales manager to obtain them.

GRAY IRON INTRODUCTION

Gray iron is the most widely used cast iron. Its main components are iron, carbon, silicon, manganese, sulfur and phosphorus. It has excellent casting properties. Here is our understanding of gray iron, including its meaning, its common grades and applications. Because of our full understanding of gray iron, we can better specify the perfect solution according to your requirements.

-

Gray Iron

Gray iron is called gray iron because its graphite structure is flaky and its fracture surface is gray. The carbon content of gray iron ranges from 2.7% to 4.0%. According to the matrix structure, gray iron can be divided into three types: ferrite, pearlite-ferrite, and pearlite. The most widely used one is pearlite gray iron. Gray cast iron has good casting performance, good vibration damping, good wear resistance, good cutting performance, and low notch sensitivity.

-

Gray Iron Grade & Applications

Ferritic gray cast iron HT100: Suitable for unimportant castings with small loads and no special requirements for friction and wear, such as protective covers, covers, oil pans, handwheels, brackets, base plates, heavy hammers, small handles, etc.

Ferritic-pearlitic gray cast iron HT150: Castings that bear medium loads, such as machine bases, brackets, boxes, tool holders, bed bodies, bearing seats, workbenches, pulleys, end covers, pump bodies, valve bodies, pipelines, flywheels, motor bases, etc.

Pearlitic gray cast iron HT200 and HT250: More important castings that bear large loads and require certain air tightness or corrosion resistance, such as cylinders, gears, machine bases, flywheels, bed bodies, cylinder blocks, cylinder liners, pistons, gear boxes, brake wheels, coupling discs, medium pressure valve bodies, etc.

Nodular cast iron HT300 and HT350: important castings that bear high loads, are wear-resistant and have high airtightness, such as the bed, base, frame of heavy machine tools, shearing machines, presses, automatic lathes, high-pressure hydraulic parts, piston rings, gears, cams, bushings with large forces, crankshafts, cylinder blocks, cylinder liners, cylinder heads of large engines, etc.

If you happen to want to customize gray iron castings, please click the button below to contact us and we will give you the best solution and quotation.

ARTICLE OF GRAY IRON SAND CASTING

Here, we have listed some articles about gray iron sand casting. They are mainly about gray iron, sand casting, and how to choose a reliable OEM factory when there are parts that need to be produced using gray iron. Of course, you can also contact our sales manager directly, who will lead a team to provide excellent service.

-

April 09, 2025

Why Choose Hulk Metal to Customize Your Plowshare for Agriculture Machinery?

READ MORE

-

March 26, 2025

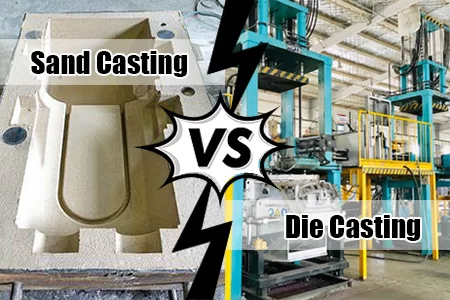

Sand Casting vs. Die Casting: Which is Right for Your Project?

READ MORE

-

March 18, 2025

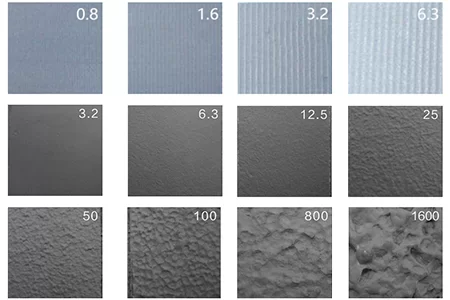

Surface Roughness Comparison of Castings with Different Materials and Processes

READ MORE

-

March 10, 2025

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

READ MORE

-

March 03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE