Our machining factory has an experienced technical team, advanced machining equipment, high-precision cutting tools, and strict production management processes. This allows us to provide you with better casting processing services.

To Supply More Precise Castings

HULK Metal Casting Machining Factory

-

Introduction

-

Equipment

-

QC Center

-

Processes

-

Parts

-

Benefits

-

Articles

-

Top

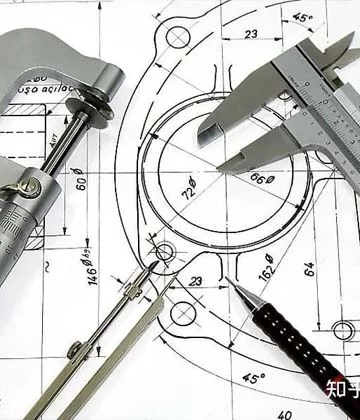

After carefully studying the casting drawings and the machining allowance left by the casting, a more complete production solution is developed. Shorten the production cycle by selecting appropriate machine and cutting tools and formulating a reasonable processing sequence. Various advanced testing instruments and strict testing processes can ensure that the quality of castings meets customer requirements. Our processing plant can process castings with 0.1-micron tolerance and RA0.1.

HULK METAL MACHINING FACTORY EQUIPMENT

Here, we show the equipment of the processing plant. This allows us to complete better casting order processing services. If you need machining services, you can contact our sales manager. He will develop a perfect solution based on your requirements and calculate a more competitive quotation.

MACHINING FACTORY MOMENT

Here is a display of castings being processed in our processing factory. Kindly contact our engineers if you want to visit the factory. They will take you to visit on-site or online and provide detailed explanations.

-

Milling

Surface accuracy and tolerances are adjusted using milling processes.

-

Adjust Flatness

Adjust the position and flatness of the casting fixation.

-

Program Adjusting

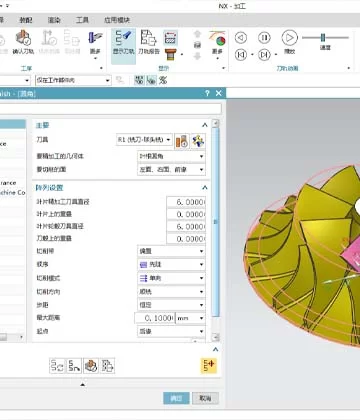

Adjust the casting and corresponding program according to the machining surface.

-

Programming

Carry out CNC programming according to drawings.

-

Turning

Castings are resized using a turning process.

HOW HULK METAL MACHINING FACTORY COMPLETE YOUR ORDERS

Develop a complete processing solution to control the cost of the entire order. Advanced production equipment and experienced production teams can complete orders more efficiently under strict procedures. Kindly contact our sales manager for solutions and better quotes.

-

PART 01Custom Solution Based on Drawings

PART 01Custom Solution Based on DrawingsThe experienced technical team will develop a solution based on the drawings that can save costs and complete the order in a shorter time with high quality and quantity.

-

PART 02Determine the Machine and Programming

PART 02Determine the Machine and ProgrammingChoose the appropriate machine tool. If it is just drilling, you can choose a drilling machine. We can select a four-axis or five-axis machine tool when castings are all-round surface polishing. Choosing the right machine tool can improve work efficiency and save processing costs.

-

PART 03Castings Fixing

PART 03Castings FixingCommon fixing methods include clamp type, magnetic suction cup, vacuum adsorption, and tooling fixation. Determining the logical relationship between the fixed surface and the processing surface can improve the processing efficiency and qualification rate of castings.

-

PART 04Machining

PART 04MachiningWe need to adjust to the corresponding program when changing the processing surface. This step is crucial, not only affecting the quality of the casting but also the equipment and tools.

-

PART 05Quantity Control

PART 05Quantity ControlThe surface accuracy, shape, and tolerance of processed castings are inspected.

-

PART 06Surface Treatment

PART 06Surface TreatmentThe mechanically processed castings then undergo powder coating, electrophoresis, passivation, hot dip plating, and other surface treatments as required to meet corrosion resistance requirements.

CASTINGS HULK METAL HAVE MACHINED

Here, we list castings that still require machining to adjust surface accuracy, hole diameter, and threads after casting. Kindly contact our sales manager if you have castings that require factory OEM. They will take you to visit the factory online or on-site and provide comprehensive services.

More Results

CHOOSE HULK METAL MACHINING YOU WILL GET

By choosing HULK Metal as your processing factory, you can reduce order costs further, save more energy and time, receive goods faster, and enjoy more comprehensive after-sales service.

-

Get Higher Quality Castings

ISO 9001-certified factories, strict production processes, experienced teams, and advanced processing equipment are the basis for our ability to deliver high-quality goods. Advanced testing equipment and strict procedures are the guarantee that we can complete orders with high quality. Kindly contact our sales manager. They will take you to visit our factory.

-

Get Goods Faster

Lead time can be effectively shortened by rationally arranging the production process. Its own logistics team can transport goods to designated ports faster. A professional freight consulting team connects you to the right freight company faster. We can achieve seamless transfer of goods to achieve faster delivery of goods.

-

Spend Less Money

When costs are controlled from each process of a complete supply chain, substantial cost savings can be achieved without affecting quality. Purchasing in larger quantities allows our supply chain to run efficiently for longer, resulting in greater cost savings. This means you spend less money to complete the order.

-

Spend Less Time & Energy

We will have a team formed of technology, procurement, production, quality inspection, freight consulting, procurement, and after-sales personnel to provide you with one-to-one service. Develop more suitable solutions and quotes based on your requirements. We provide lifelong services to help you solve various problems during the purchasing process.

ARTICLES OF METAL CASTING & MACHINING

Here are the articles we have compiled about casting processing. You can find what you want to know here. Kindly contact us if you have a casting order and need OEM.