HULK Metal is committed to providing excellent and complete die-casting services to become a top die-casting foundry. Contact us for a free solution and quote.

HULK Metal

Better Die Casting Services Supplier

-

Advantages

-

Capacities

-

Processes

-

Parts

-

Types

-

Foundry

-

Introduction

-

Articles

-

Review

-

Top

START DIE CASTING SERVICES AT HULK METAL.

This is the foundation of our services, and these advantages let us provide excellent die-casting services. We will continue to grow to provide better services. Contact us now for a free solution and quote.

-

Foundry:

HULK Metal's die-casting foundry is ISO 9001 certified. The die-casting workshop has ten sets of die-casting machines, one each of 4500 tons, 2500 tons, and 1600 tons; it has eight machining centers and 26 CNC machine tools; it has a welding center, a surface treatment center, and a quality control center. We have sufficient production capacity to receive large-volume orders. Because the cost of making die-casting molds is relatively high, investment casting can be used instead of die-casting to complete the order when necessary. We will develop a perfect solution based on your drawings.

-

Experience:

We only provide aluminum die-casting services and can produce aluminum die-casting parts from ADC1,3,5,6,10,12,14aluminum alloy. We have provided high-quality solutions for the communications industry, home appliance manufacturing, furniture manufacturing, power transmission industry, lighting manufacturing, automobile manufacturing, etc., and delivered tens of thousands of orders. If you want to find a die-casting foundry to complete your order, you can contact us for a free quote and solution.

-

Quality:

The quality control center has complete quality inspection equipment such as CMM, electron microscope, flaw detector, salt spray test room, chemical testing equipment, hardness tester, thickness meter, etc. We can detect the size of the product, pores, chemical composition, corrosion resistance, coating thickness, surface gloss and color difference, etc. We will develop quality inspection plans and issue material and product testing reports based on customer requirements.

-

Service:

Our service center provides technical support to develop a complete solution based on your required delivery time, delivery method, order quantity and drawings, and complete price calculations. We support on-site and on-site factory visits, support a variety of delivery methods, and can ship worldwide. We provide after-sales service and quality assurance service. Providing high-quality services is our service tenet. We will humbly accept your suggestions and continue to improve.

DIE CASTING SERVICES CAPACITIES

Here, we introduce our die-casting service capabilities from materials, maximum die-casting weight, production capacity, certification and finishing, and services. Due to space limitations, we cannot introduce it in detail. Contact our engineers for the details.

MANUFACTURING: | According To the Drawings Or Samples |

SERVICE METHOD: | OEM |

MATERIALS: | ADC1,3,5,6,10,12,14 |

PROCESS: | High Pressure Die Casting |

WEIGHT: | <=2 Tons/piece |

PRODUCTION CAPACITY: | 500 tons / month |

CERTIFICATION: | ISO 9001, IATF 16949 |

FINISHING: | CNC Machining, Surface Treatment |

MOQ: | 500KG / A Standard Tray |

HOW YOUR DIE CASTING PARTS PRODUCED

Here, we will briefly introduce how the die-casting foundry completes the production of orders. Die casting parts have precision and surface quality unmatched by other casting processes. Castings can be put into use directly without processing. If you want to know more, kindly contact our engineers.

-

01

Customize Solutions

Before the order starts production, we will develop a complete solution according to your requirements and discuss its feasibility with you. After getting your agreement, we will begin mold manufacturing and sample trial production.

-

02

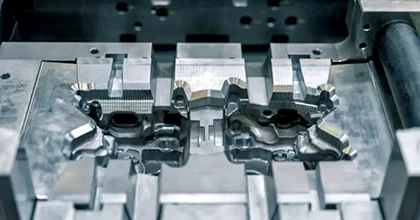

Mold Making

The material of die-casting molds is mainly hot work mold steel H13, as well as high-end mold materials such as KD61, DAC55, DHA1, 8407, W302, and 8418, which have better performance but are more expensive. For more details, kindly contact our engineers.

-

03

Mold Installation & Commissioning

The mold is installed on the die-casting machine for all-round debugging. Ensure that the mold can be closed tightly and that liquid aluminum can be injected into the cavity. It will be used after debugging is completed. Whether it is hot chamber die casting or cold chamber die casting, the mold needs to be preheated before starting production.

-

04

Mold Closing & Preheating

The first step in production is to close the mold, which is then heated to a specific temperature. Preheating has several purposes; 1. Reduce the number of hot mold parts and improve production efficiency, 2. Extend the service life of the mold; 3. Reduce production costs.

-

05

Injection & Cooling

Use an injection gun to inject liquid metal into the mold cavity at high pressure until it is full. Water passes the mold and cools it. After cooling, separate the mold to reveal the molded die casting parts. The casting will be automatically demoulded and dropped into a prepared container.

-

06

Heat Treatment

Workpieces produced by high-pressure die casting can not require heat treatment, while workpieces produced by low-pressure die casting and gravity casting can require heat treatment. Because there will be blistering inside the high-pressure die-casting workpiece, the workpiece will be deformed and warped during heat treatment.

-

07

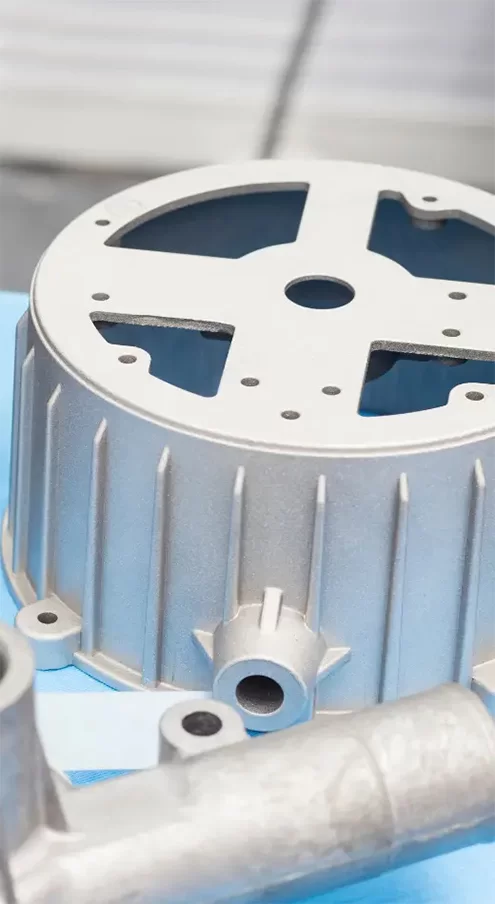

Finishing

The semi-finished product undergoes CNC processing to adjust the shape and size of the die casting further. The finished product is then obtained through surface treatment processes such as powder spraying, polishing, and electrochemical treatment.

-

08

Quality Control

Our quality center can develop inspection plans based on the shape, size, tolerance, surface roughness, hardness, and other die castings requirements and issue inspection reports on materials and finished products.

-

09

Packaging & Delivery

We provide customized packaging services, such as packaging materials, internal filling, packaging printing, etc. We provide freight consulting services and can use our extensive resources to help you find a better freight company.

-

010

After Service

We will provide comprehensive after-sales service to protect the rights and interests of our customers. We believe high-quality services will win customers' trust, just like high-quality products.

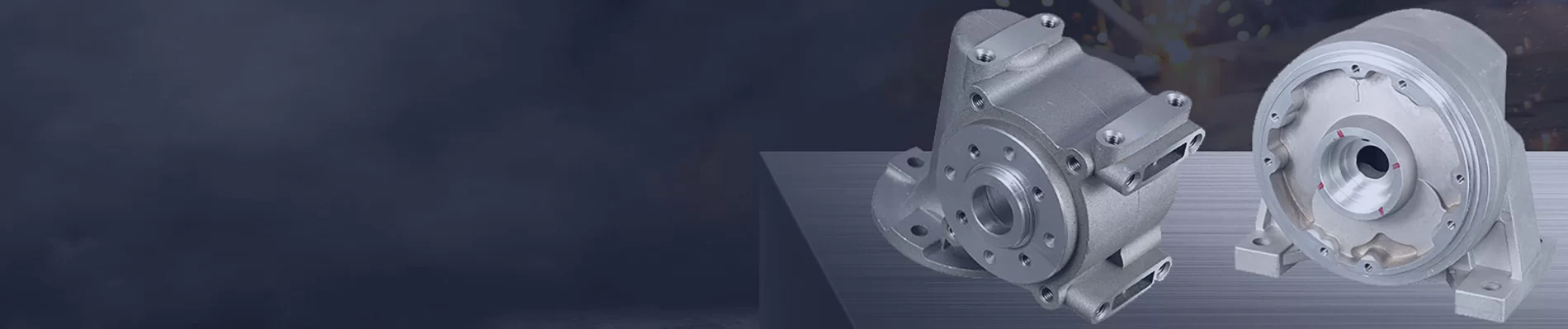

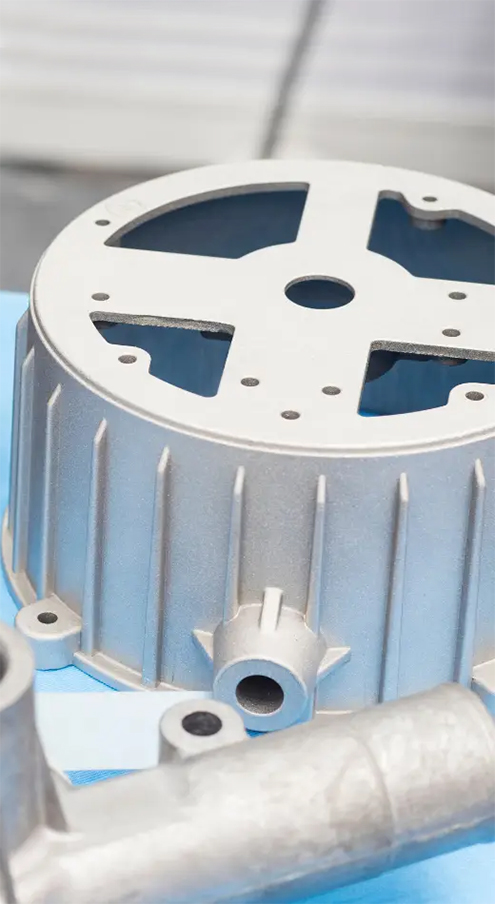

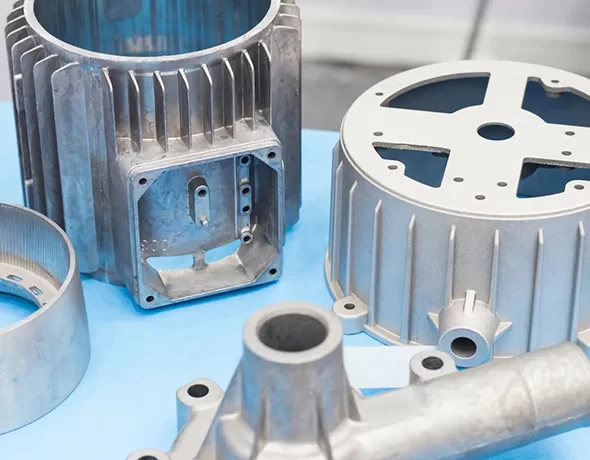

PARTS HULK METAL DIE CASTING FOUNDRY PRODUCED

These are accessories that have been produced in our die casting foundry. These pictures are only used to represent that we have produced these products and do not represent that we have produced them. No customer information will be disclosed to anyone without permission. You can provide drawings or samples. We will help you develop a solution for free and at a great price.

More Results

DIE CASTING TYPES HULK METAL CAN SUPPLY

We currently only offer aluminum die casting services. We can help you develop alternatives based on the material of your casting.

VISIT HULK Metal DIE CASTING FOUNDRY

Our die-casting foundry has dozens of die-casting machines, such as a 4,500-ton, a 2,500-ton, and other capabilities. Our quality control center can detect die castings' shape, hardness, internal structure, and other mechanical properties according to your needs. We introduce simple here. You can click to learn more or contact our project to visit online or on-site.

-

Equipment

Die-casting machines with different capabilities can better adapt to orders with different volume and structural requirements, improve order production efficiency, and reduce costs.

-

QC Center

It can complete the testing of the metallographic, shape, size, hardness, surface roughness, and mechanical properties of materials and finished products with high quality and issue reports.

-

Production Team

With rich experience, he can better operate and repair equipment, complete every job carefully, and ensure the completion of orders with high quality.

DIE CASTING SERVICES INTRODUCTION

Here, you can fully understand the die-casting process from the concept of die-casting and the advantages and disadvantages of die-casting. We also briefly describe the benefits you can enjoy when choosing our die casting services.

-

Die Casting Means:

Die casting is a casting process that uses pressure to inject liquid metal into a metal mold cavity and obtain a workpiece after cooling. The materials are usually aluminum, zinc, copper, lead, tin, and their alloys. Die casting is divided into cold chamber die casting and hot chamber die casting, which can also be called low-pressure and high-pressure die casting. The main processes of die casting are mold manufacturing, mold assembly and debugging, mold coating and mold closing, liquid metal injection, and pressure maintenance, cooling mold opening, casting cleaning, and finishing. Parts produced by die-casting include engine cylinder blocks, cylinder heads, gearbox cases, engine hoods, instrument and camera casings and brackets, pipe joints, gears, etc.

-

Advantages & Disadvantages of Die Casting:

Advantages:

1. High productivity, easy to realize mechanization and automation; 2. Thin-walled castings with complex shapes can be produced; 3. Castings have high dimensional accuracy and small surface roughness; 4. Parts can be embedded in die castings.

Disadvantages:

1. Castings are prone to defects such as pores and cracks; 2. The cost of die-casting molds is high and is not suitable for small-batch casting production; 3. Due to the limitations of the clamping force and die size of the die-casting machine, it is not suitable for the production of large die-castings; 4. The materials of die-castings are limited.

What You Will Get When Choose Our Die Casting Service.

When you choose our casting services, we will calculate the price and develop a perfect solution for free. We will save costs as much as possible while ensuring quality; we will complete orders as quickly as possible within a limited budget; we will provide as many services as possible to make the process easier; we will provide after-sales service and do our best to ensure your rights and interests.

ARTICLE OF DIE CASTING

Here, you can see some articles about die-casting, which are notes we summarized as we continue to grow. There will be the details of die-casting, die-casting materials, and how to choose a more suitable die-casting factory. If you want to know about our die-casting services, kindly leave a message.