HULK Metal has been working hard to learn more and advanced sand casting techniques and is engaged in becoming a better sand casting foundry to provide more customers with higher quality sand casting services.

HULK Metal

Top Sand Casting Services Supplier

-

Advantages

-

Capacities

-

Processes

-

Parts

-

Types

-

Foundry

-

Introduction

-

Articles

-

Review

-

Top

START SAND CASTING SERVICES at HULK METAL

We will continue to improve our sand casting services capabilities from the four aspects of foundry, experience, quality, and service. To provide more customers with higher quality sand castings. You can contact us online or visit our sand casting foundry.

-

Foundry:

HULK Metal can provide sand casting services using clay, water glass, and synthetic resin as binders to produce sand castings with more complex shapes, heavier weight, and higher precision requirements. If you need smaller quantities, simpler shapes, and heavier castings, manual molding services can save a lot of costs. Instead, we arranged a fully automated sand casting service.

-

Experience:

We have produced 316 stainless steel castings for the food machinery industry, ductile iron castings for the textile machinery industry, and supply sand casting services for other metal parts for more than 20 industries, such as mining machinery, agricultural machinery, and the construction industry. We can formulate perfect sand casting solutions and calculate a more competitive price according to drawings and particular requirements.

-

Quality:

Our quality control center will follow up on the entire production process of your order. We have professional testing equipment, our quality inspection team has rich experience, and they have strict testing procedures. They will strictly test the material, shape, tolerance, and performance of sand castings according to requirements. We also focus on service quality. So we will take every valuable suggestion seriously.

-

Services:

We are constantly integrating the supply chain to provide more comprehensive services. So far, we have been able to provide procurement, production, quality inspection, finishing, surface treatment, and other services, support a variety of delivery methods, and global delivery. We set up a freight consulting team to help you find a better freight company and after-sales team to deal with your after-sales problems. At HULK Metal, you can enjoy different sand casting services.

SAND CASTING SERVICES CAPACITIES

Here, we introduce the sand casting services we can provide in terms of materials, processes, piece weight, production capacity, certification, and machining. In terms of tolerances, it is necessary to choose the correct processes according to the specific requirements of sand castings, but these are marked on the drawings. You could give us the drawings and let our engineers develop a solution with a price.

MANUFACTURING: | According To the Drawings Or Samples |

SERVICE METHOD: | OEM |

MATERIALS:

| Ductile Iron, Malleable Iron, Gray Iron, Carbon Steel, Stainless Steel, Brass, Aluminum and Its Alloy |

PROCESS:

| water glass, coated sand, resin sand, and other sand-casting |

WEIGHT: | <=2 Tons/piece |

PRODUCTION CAPACITY: | 500 tons/month |

CERTIFICATION: | ISO 9001, IATF 16949 |

FINISHING: | Heat Treatment, CNC Machining, Surface Treatment |

MOQ: | 500KG / A Standard Tray |

HOW YOUR SAND CASTING PARTS PRODUCED

Here, we will introduce how to use the sand casting process to complete your sand castings. Of course, these are not all processes. If you want to learn more, you can contact our engineers. Our colleagues will take you on an online or on-site tour of the sand casting plant.

-

01

Customize Solutions

First, we will develop a complete solution based on the drawings, order quantity, delivery time, and price requirements you provide.

-

02

Mold Making

We will use resin, clay, and water glass as binders and siliceous sand, quartz sand, corundum sand, and chromite sand to make sand cores and molds. There are two production methods: mechanical and manual.

-

03

Metal Smelting

Use a crucible to heat and melt the metal and add the other metals sequentially at the appropriate time. In this way, liquid metals with different casting properties can be obtained. We use eddy current electric heating because it is more environmentally friendly.

-

04

Pouring

Liquid metal is poured into closed sand molds. The pouring has mechanical and manual two ways. Using the appropriate pouring method can effectively control the production cost.

-

05

Cleaning and Recycling

After the sand mold has cooled, separate castings and recover the sand for reuse. Sand castings need to cut off the excess parts. If it is a tree-forming mold, we need to cut castings down, and then the residue on the surface should be removed by shot blasting and other treatments.

-

06

Finishing

Use CNC machining to complete further adjustments to the shape and surface of the sand casting to achieve the shape, surface roughness, and tolerance required by the customer. The processes usually required are turning, milling, tapping, drilling, etc. After surface treatment, such as galvanizing and powder coating. At last, obtain the finished product.

-

07

Quality Control

We will complete the inspection of the castings' shape, size, surface roughness, hardness, ductility, brittleness, and other aspects according to requirements and issue material and product testing reports.

-

08

Packaging & Delivery

We provide wooden boxes, cardboard boxes, and other packaging materials boxes. Styrofoam and bubble paper are used to fill between products. We can also customize according to customers' requirements. Find better freight companies for faster delivery by the freight consulting services we provide.

-

09

After Service

We will provide comprehensive after-sales service to ensure the overall quality of the order. We hope that our customers will provide valuable feedback on our services, which is the source of our continuous improvement.

PARTS HULK METAL SAND CASTING FOUNDRY PRODUCED

These are parts that our sand casting foundry has produced. You can rest assured that these pictures are from the Internet, and we will never show product pictures and parameters to anyone without the customer's permission.

More Results

SAND CASTING TYPES HULK METAL CAN SUPPLY

We use materials as one of the ways to classify sand castings to facilitate customers to find what they want to know based on metal casting materials. You can contact us to learn more and get a quality solution and quote.

Ductile Iron Sand Casting

Gray Iron Sand Casting

Iron Sand Casting

Malleable Iron Sand Casting

Sand Casting Brass

Sand Casting Aluminum

Sand Casting Steel

Stainless Steel Sand Casting

-

Ductile Iron Sand Casting

It uses ductile iron as raw material to complete gray iron castings with specific shapes, sizes, surface roughness, and performance through the sand casting process. Choosing the appropriate binder can shorten lead time and reduce costs effectively. For example, ductile iron castings cast using resin sand will have higher precision and can reduce part of the CNC machining process. Common ductile iron castings include power machinery crankshafts, camshafts, connecting shafts, connecting rods, clutch plates, hydraulic cylinders, pipe fittings, etc.

-

Gray Iron Sand Casting

It uses gray iron as raw material and uses an optimized sand casting process to complete gray iron castings with specific shapes, sizes, surface roughness, and properties. The optimized gray iron sand casting process can effectively shorten lead time, improve the casting qualification rate, and reduce costs. Common gray iron castings include internal combustion engine cylinder blocks, cylinder heads, cylinder liners, piston rings, exhaust pipes, etc. In addition to completing orders, our gray iron sand casting services also include free freight consultation and comprehensive quality assurance services.

-

Iron Sand Casting

It uses iron as raw material and uses the sand casting process to complete the production of castings through core making, mold closing, iron smelting, pouring, cooling, cleaning, heat treatment, finishing, surface treatment, and other processes. Iron sand casting services also require a complete production plan based on the castings' shape, size, surface roughness, and performance to reduce the production cost of the order, shorten the lead time, and improve the order qualification rate. Iron can also be divided into gray iron, ductile iron, malleable cast iron, etc. You can contact us, and we will help you formulate a perfect solution and calculate a better price.

-

Malleable Iron Sand Casting

Malleable Iron has high strength, plasticity, and impact toughness and can replace carbon steel in some scenarios. Malleable Iron sand casting can complete reducer housings, pipe fittings, valve bodies, etc. We will develop a solution and calculate the price after receiving your drawings. The plan will include production method, delivery time, delivery method, packaging method, etc. We will provide comprehensive after-sales service to protect your rights and interests.

-

Sand Casting Brass

It is a process in which foundries use sand casting to produce copper castings. The primary sand-casting brass service provided by HULK Metal is copper valve casting. Our foundry strictly implements an ISO 9001 quality management system. Our quality control center will develop a quality inspection plan based on your requirements. Orders will not only be completed on time but also quantity and quality are guaranteed.

-

Sand Casting Aluminum

It is a process in which a foundry uses casting sand and binders to make a casting mold manually or mechanically, pours liquid aluminum into the mold, cools it, and then performs finishing to obtain aluminum castings with specific shapes, properties, and sizes. Aluminum foundries can be divided into industrial level (mass production of aluminum castings) and workshop level (customized specific processes) according to their business scope—industrial grade Sand Casting Aluminum services provided by HULK Metal. We can help you customize a complete solution.

-

Sand Casting Steel

The foundry uses the casting process to make carbon steel, stainless steel, and alloy steel into specific shapes, sizes, and properties using the sand casting process according to the drawings and specific requirements. HULK Metal provides mass production services for steel castings. We will understand your needs first, formulate a complete solution based on your drawings, and then complete the order efficiently and with high quality through strict production and quality inspection processes.

-

Stainless Steel Sand Casting

It uses stainless steel as raw material, melts it at high temperature, pours it into a sand mold, waits for cooling, and then finishes to obtain a stainless steel casting. Because the price of stainless steel materials is high, if ordinary sand casting is used and then processed, it will not only cause a waste of material but may also cause the casting to be unqualified. Therefore, we usually use resin or coated sand casting to complete customer orders. You can contact us for our solutions and quotes.

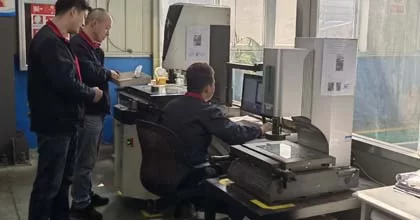

VIEW HULK METAL SAND CASTING FOUNDRY

These are the bases why we can provide you with higher quality sand casting services - new and comprehensive sand casting equipment, a professional quality control center, and an experienced production team. You can click to learn more or contact our engineers to visit the sand casting foundry online or on-site.

-

Equipment

Large-volume orders can be completed faster and at lower cost through mechanical molding, fully automatic pouring, and other equipment. And small orders can be made manually to reduce costs.

-

Production Team

They have rich experience, can skillfully operate various equipment, and complete the work to ensure that orders can be completed faster and with higher quality.

-

QC Center

Our QC center has electron microscopes, hardness testers, impact testing machines, and salt spray testers to issue material and product testing reports according to your requirements.

SAND CASTING SERVICES INTRODUCTION

This section will introduce you to the content of sand casting services, such as what sand casting means, its advantages and disadvantages, and the characteristics of sand casting services provided by HULK Metal. Our engineers can help you customize a solution and price for free. Contact us.

-

Sand Casting Services Means

Sand casting is a foundry that uses foundry sand to create a mold with a cavity and a pouring opening based on the product model or sample. The required metal is melted and poured into the mold. After cooling, it is obtained through cleaning, cutting, finishing, and other processes. Get castings with specific shapes, sizes, and properties. Sand casting can be classified according to the binder into water glass sand casting, clay sand casting, resin sand casting, etc. Choosing the appropriate sand casting process according to casting requirements can reduce production costs and time and improve casting qualification rates.

-

Advantages and Disadvantages of Sand Casting

Advantages:

1. Can complete castings of a variety of materials, 2. Can complete castings from several grams to several tons, 3. The process is relatively simple and the production cost is relatively low.

Disadvantages:

1. Limited by the process, there will be pores inside the casting. 2. The production cycle will be longer than other processes. 3. Unable to cast smaller and more precise metal pieces.

HULK Metal also manufactures standardized products such as handrails and guardrails systems, concrete precast accessories, glass clamps, and aluminum-plastic panels.

ARTICLE OF SAND CASTING

Here, we compile articles about sand casting in our continuous learning and progress. They have raw materials, sand casting types, Casting process flows, and their advantages and disadvantages. You can learn more about sand casting and our services here.

-

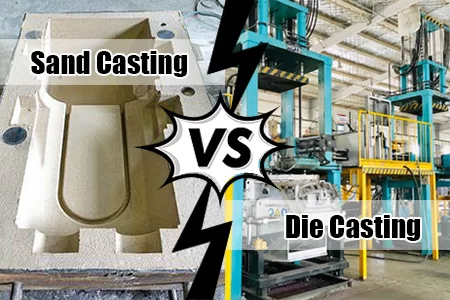

March 26, 2025

Sand Casting vs. Die Casting: Which is Right for Your Project?

READ MORE

-

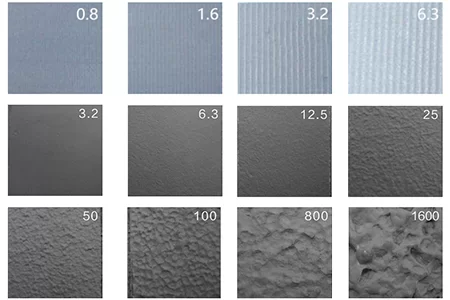

March 18, 2025

Surface Roughness Comparison of Castings with Different Materials and Processes

READ MORE

-

March 10, 2025

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

READ MORE