Here is our understanding of casting and casting-related knowledge over the years. They can help you understand casting clearly and choose a more suitable OEM factory.

HULK Metal Casting Blog

Supply Useful Metal Casting Information

News

The latest developments of HULK Metal, factory live broadcasts, etc. can be seen here.

-

172024.09Hulk Metal: Empowering Employees Through Regular Training for Industry Excellence

172024.09Hulk Metal: Empowering Employees Through Regular Training for Industry ExcellenceIn the highly competitive landscape of the metal casting and manufacturing industry, Hulk Metal has emerged as a leader not only in producing top - notch products but also in investing in its most valuable asset - its employees.

-

182024.01Hulk Metal Casting Factory Implements Comprehensive Safety Regulations to Build Solid Safety Production Lines!

182024.01Hulk Metal Casting Factory Implements Comprehensive Safety Regulations to Build Solid Safety Production Lines!Recently, Hulk Metal's casting foundry has achieved remarkable results in ensuring the safety of the factory and personnel due to the comprehensive implementation of daily safety regulations, which has attracted industry attention.

Technology

Here is related content about metal casting, such as material types, properties, advantages, disadvantages and applications, types of processes, advantages, disadvantages, and applications, and so on. Kindly Contact us to get more.

-

Experience

-

Materials

-

Metal Casting

-

CNC Machining

-

Surface Treatment

-

April 23, 2025

How to Find A Cost-Efficient Metal Casting Manufacturer?

READ MORE

-

122025.03

Applications of Stainless Steel Castings in Medical Devices

Applications of Stainless Steel Castings in Medical DevicesIn the highly specialized and safety - critical field of medical devices, the choice of materials is of utmost importance. Stainless steel castings have emerged as a cornerstone in the manufacturing of a wide range of medical devices, offering a unique combination of properties that ensure both functionality and patient safety. This blog post delves into the various applications of stainless steel castings in medical devices, exploring the reasons behind their widespread use.

-

252025.02

How to Compare Product Quality Between Different Casting Foundries?

How to Compare Product Quality Between Different Casting Foundries?In the vast field of manufacturing, casting, as a basic and key process, plays a decisive role in the quality and performance of many products. Because the quality of casting products is so critical, it is particularly important to choose a foundry with excellent product quality. But among the many foundries, how to accurately compare their product quality? Next, let's explore this key issue in depth.

-

182024.11

What Should Casting Manufacturers Pay Attention to in Production Management?

What Should Casting Manufacturers Pay Attention to in Production Management?Casting manufacturers are engaged in a complex production process that encompasses multiple stages and requires meticulous management to ensure product quality and production efficiency. Here are the key aspects of management that casting manufacturers need to pay attention to during the production process.

-

-

February 14, 2025

What Are The Metal Casting Materials Commonly Used in Foundries?

READ MORE

-

092025.01

How to Select The Right Raw Materials for Casting Foundries?

How to Select The Right Raw Materials for Casting Foundries?In the world of foundry operations, the selection of raw materials is a decision that can make or break the quality of the final product. Foundries are responsible for transforming raw materials into a wide range of metal products, from intricate automotive parts to massive industrial machinery components. The right choice of raw materials is essential for ensuring the mechanical properties, dimensional accuracy, and overall performance of the castings. In this blog post, we will explore the key considerations that foundries must take into account when choosing raw materials.

-

092024.12

Differences in Wax Materials for Precision Casting

Differences in Wax Materials for Precision CastingIn the field of metal processing, casting is an important means. It is widely used in many industries because it can transform metal materials into parts of various shapes and specifications. The choice of casting materials plays a decisive role in the quality, performance and production cost of the final castings. There are many kinds of casting materials commonly used in foundries, and each material has a unique scope of application, selection criteria, advantages and disadvantages.

-

-

March 28, 2025

Everything You Need to Know About Die Casting!

READ MORE

-

262025.03

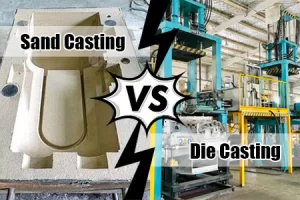

Sand Casting vs. Die Casting: Which is Right for Your Project?

Sand Casting vs. Die Casting: Which is Right for Your Project?In the world of metal casting, two popular methods stand out: sand casting and die casting. Each has its own unique characteristics, advantages, and applications. If you're involved in manufacturing or product development, understanding the differences between these two processes can help you make an informed decision for your next project.

-

102025.03

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting PartsIn the world of manufacturing, precision casting has emerged as a highly effective method for producing complex and intricate metal components with tight tolerances. Whether it's for the aerospace, automotive, medical, or any other industry that demands high-precision parts, ensuring the accuracy of metal castings is of utmost importance. In this blog post, we will delve into the various factors and techniques involved in achieving precision in precision casting, exploring how manufacturers can overcome challenges and produce metal parts with the highest level of accuracy.

-

032025.03

Addressing Defects in Castings: A Comprehensive Guide

Addressing Defects in Castings: A Comprehensive GuideCasting is a widely used manufacturing process that involves pouring molten metal into a mold cavity and allowing it to solidify. It offers numerous advantages, such as the ability to create complex shapes, high production rates, and cost-effectiveness. However, despite its many benefits, casting can also be plagued by various defects that can compromise the quality, performance, and safety of the final product. Defects in castings can lead to costly rework, production delays, and even customer dissatisfaction. Therefore, it is crucial for manufacturers to understand the common causes of casting defects and implement effective strategies to prevent and address them.

-

-

April 14, 2025

CNC Milling vs. CNC Turning: Unraveling the Key Differences for Your Project

READ MORE

-

252025.03

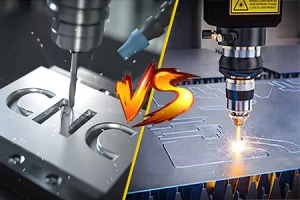

CNC Cutting vs. Laser Cutting: Which One is Right for Your Project?

CNC Cutting vs. Laser Cutting: Which One is Right for Your Project?In the world of manufacturing and fabrication, choosing the right cutting method is crucial. Two popular options that often come under consideration are CNC (Computer Numerical Control) cutting and laser cutting. Each has its own set of unique characteristics, advantages, limitations, and ideal applications. Let's take a deep dive into the differences between these two cutting processes to help you make an informed decision for your next project.

-

062025.03

CNC Machining vs. Metal Casting: Unraveling the Differences for Optimal Manufacturing

CNC Machining vs. Metal Casting: Unraveling the Differences for Optimal ManufacturingWhen it comes to manufacturing, both CNC machining and metal casting are widely used to create complex metal parts. Each of these processes has distinct advantages and applications, but how do you decide which one is best suited for your project? In this blog, we’ll compare CNC machining and metal casting, highlighting their differences, benefits, and drawbacks, so you can make an informed decision that best meets your production needs.

-

FAQ

Here is a collection of questions from customers and some simple answers. Kindly contact our engineers if they cannot resolve your issue.

-

Produce

-

Materials

-

Policy

-

Order

-

Service

-

The general process of casting production is to make molds, melt raw materials, pour, cool, clean, and finishing to finish products. Many casting processes are derived from this process. This answer briefly summarizes this content. Kindly search for other content on the website to fully understand it.

-

The general process for making sand casting molds is to make two upper and lower sandboxes, make a casting pattern, mix sand and binder, fill it into the sandbox with the pattern and vibrate it, take out the pattern, put it in the sand core and close the box. The method or whether to remove the pattern needs to be determined according to the casting process. For example, the pattern of investment casting is taken out through high-temperature evaporation, while the pattern of lost foam casting does not need to be taken out. We will introduce it in more detail below.

-

Aluminum is extremely popular. It has a low density, good corrosion resistance, and high thermal conductivity, making it suitable for a wide range of applications, from aircraft parts to cookware. Iron, especially cast iron, is another commonly cast metal. It has excellent castability and high compressive strength and is often used in engine blocks, pipes, and machinery parts. Copper and its alloys, such as brass and bronze, are also widely cast. They offer good electrical and thermal conductivity as well as attractive aesthetic properties, which is why they are used in electrical components, decorative items, and musical instruments.

-

1. Castings' drawings (2D or 3D) If there are no drawings, samples can be provided

2. Material (if not on the drawing)

3. Quantity

4. Delivery terms

Our colleagues will give you a better quote after understanding your needs more deeply.

-

We need to decide based on the complexity of the casting, the quantity you require, the quantity of a single delivery, and many other factors. For a specific delivery period, our sales manager will lead the service team to develop a solution that satisfies you based on your requirements.

-

T/T(For big orders, 30-90 days can be acceptable), L/C, for other methods please contact our sales manager.

-

You only need to give us the following information to get a simple quote:

1. Drawings (2D or 3D) If there are no drawings, samples can be provided.

2. Material (if not on the drawing)

3. Quantity

4. Delivery terms

Our colleagues will give you a more detailed quote after understanding your needs more deeply.

-

Yes, we support return, replenishment, and exchange services. Any products with quality defects will be dealt with in the best possible manner after being confirmed. We will actively deal with any of your questions. For more than 20 years, the feedback we have received from our customers on our products has been consistently positive.