Applications of Stainless Steel Castings in Medical Devices

-

Home>

-

Blog>

-

Technology>

Applications of Stainless Steel Castings in Medical Devices

In the highly specialized and safety - critical field of medical devices, the choice of materials is of utmost importance. Stainless steel castings have emerged as a cornerstone in the manufacturing of a wide range of medical devices, offering a unique combination of properties that ensure both functionality and patient safety. This blog post delves into the various applications of stainless steel castings in medical devices, exploring the reasons behind their widespread use.

Understanding Stainless Steel Castings

Before we look at their applications in medical devices, it is essential to understand what stainless steel castings are. Stainless steel is an alloy that typically contains iron, chromium, and, in some cases, nickel and other metals. The addition of chromium gives stainless steel its characteristic corrosion resistance, which is a crucial property in medical applications.

Stainless steel castings are made by pouring molten stainless steel into a mold and allowing it to solidify. This manufacturing process allows for the creation of complex shapes and precise dimensions, making it suitable for a variety of medical device components.

Advantages of Stainless Steel Castings in Medical Devices

Biocompatibility

One of the most significant advantages of stainless steel castings in medical devices is their biocompatibility. Stainless steel is generally well - tolerated by the human body, with a low risk of causing allergic reactions or other adverse effects. This makes it a safe choice for use in implants and surgical instruments that will come into direct contact with tissues and fluids.

Corrosion Resistance

As mentioned earlier, corrosion resistance is a key property of stainless steel. In the medical field, where devices are often exposed to body fluids, saline solutions, and other corrosive substances, this property is crucial. Stainless steel castings can maintain their structural integrity and performance over time, reducing the risk of device failure and the need for frequent replacements.

Strength and Durability

Medical devices need to be able to withstand various mechanical stresses, such as the forces exerted during surgery or normal body movements. Stainless steel castings offer a high level of strength and durability, allowing them to perform reliably in these demanding environments. They can also be designed to have specific mechanical properties, such as high tensile strength or fatigue resistance, depending on the application.

Ease of Fabrication and Sterilization

Stainless steel castings can be easily fabricated into complex shapes and sizes, which is beneficial for manufacturing a wide range of medical devices. Additionally, stainless steel is resistant to most sterilization methods, including autoclaving, chemical sterilization, and gamma radiation. This makes it easy to ensure the sterility of medical devices made from stainless steel castings.

Applications of Stainless Steel Castings in the Medical Field

Stainless steel castings are used in various medical applications due to their superior properties. Some key applications include:

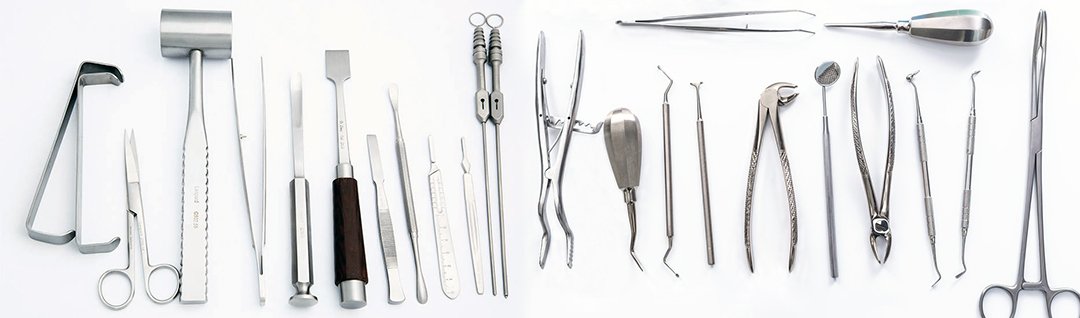

Surgical Instruments

Surgical tools must be highly precise, easy to sterilize, and resistant to wear. Stainless steel castings are used to manufacture forceps, scalpels, retractors, and scissors. The strength and corrosion resistance of stainless steel ensure these instruments perform reliably over numerous procedures.

Orthopedic Implants and Prosthetics

Orthopedic implants, such as hip and knee replacements, require high-strength and biocompatible materials. Stainless steel castings provide the necessary mechanical properties to support weight-bearing functions while ensuring patient safety.

Diagnostic and Imaging Equipment

MRI machines, CT scanners, and X-ray devices incorporate stainless steel components in their structural frameworks. The non-magnetic properties of certain stainless steel grades make them suitable for imaging equipment where electromagnetic interference must be minimized.

Hospital Furniture and Support Equipment

Stainless steel castings are used in hospital beds, operating tables, IV stands, and wheelchairs due to their strength, hygiene, and ease of sterilization. Their durability ensures long service life in demanding hospital environments.

Dental Instruments and Implants

From orthodontic brackets to dental tools like forceps and drills, stainless steel castings play a crucial role in the dental industry. Their biocompatibility and resistance to corrosion make them an excellent choice for both reusable and implantable dental devices.

Manufacturing Process of Stainless Steel Castings for Medical Use

The production of stainless steel castings for medical applications involves precise and controlled processes to meet strict industry standards. The key steps include:

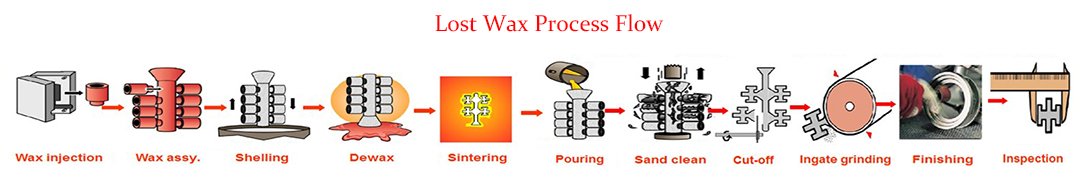

Investment Casting (Lost Wax Process)

This process allows for the production of intricate components with smooth surfaces and precise dimensions. A wax model of the component is created, coated with ceramic, and then melted out to create a mold for the molten stainless steel.

Material Selection

Medical-grade stainless steels such as 316L and 17-4 PH are commonly used for their biocompatibility and mechanical properties.

Heat Treatment and Surface Finishing

Heat treatments improve mechanical properties, while electropolishing or passivation ensures a smooth, clean surface free from contaminants.

Quality Control and Certification

Medical device components must comply with stringent regulatory standards such as ISO 13485, FDA requirements, and ASTM F138 for surgical implants.

Considerations When Choosing Stainless Steel Castings for Medical Devices

To ensure optimal performance and safety, several factors must be considered when selecting stainless steel castings for medical applications:

Regulatory Compliance

Ensure the chosen stainless steel alloy meets medical industry standards and regulatory requirements.

Sterilization Compatibility

The material should withstand repeated sterilization cycles without degradation.

Mechanical Properties

The required strength, hardness, and wear resistance should align with the intended application.

Surface Finish

Smooth surfaces reduce bacterial adhesion and improve sterilization efficiency.

Customization and Precision

Advanced manufacturing techniques should allow for tailored designs that meet specific medical needs.

Future Trends in Stainless Steel Castings for Medical Applications

The medical industry continuously evolves, and advancements in stainless steel casting technology further enhance device performance. Key trends include:

Additive Manufacturing Integration

Combining investment casting with 3D printing allows for faster prototyping and customized implants.

Improved Biocompatible Coatings

Surface modifications, such as titanium coatings, enhance compatibility with human tissue.

Enhanced Corrosion Resistance Alloys

New stainless steel compositions provide even greater resistance to harsh sterilization processes.

Automation in Manufacturing

AI-driven quality control and robotic precision machining improve production efficiency and consistency.

Conclusion

Stainless steel castings play an indispensable role in the medical industry, providing strength, corrosion resistance, and biocompatibility required for surgical instruments, implants, diagnostic equipment, and hospital furnishings. With ongoing advancements in material science and manufacturing techniques, stainless steel castings will continue to contribute to medical innovations, ensuring safer and more effective healthcare solutions.

For medical device suppliers seeking reliable stainless steel casting solutions, partnering with an experienced and certified casting manufacturer is essential to achieving high-quality, precision-engineered components that meet stringent medical standards. Hulk Metal happens to be such a casting manufacturer that meets international standards. If you have any ideas about stainless steel casting or need to customize any stainless steel castings, please feel free to contact us.

Article Navigation

Article Navigation

Industries

Foundries

-

March.10, 2025

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

READ MORE

-

March.03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE

-

February.25, 2025

How to Compare Product Quality Between Different Casting Foundries?

READ MORE

-

February.14, 2025

What Are The Metal Casting Materials Commonly Used in Foundries?

READ MORE

-

January.09, 2025

How to Select The Right Raw Materials for Casting Foundries?

READ MORE

-

November.18, 2024

What Should Casting Manufacturers Pay Attention to in Production Management?

READ MORE