CNC Cutting vs. Laser Cutting: Which One is Right for Your Project?

-

Home>

-

Blog>

-

Technology>

CNC Cutting vs. Laser Cutting: Which One is Right for Your Project?

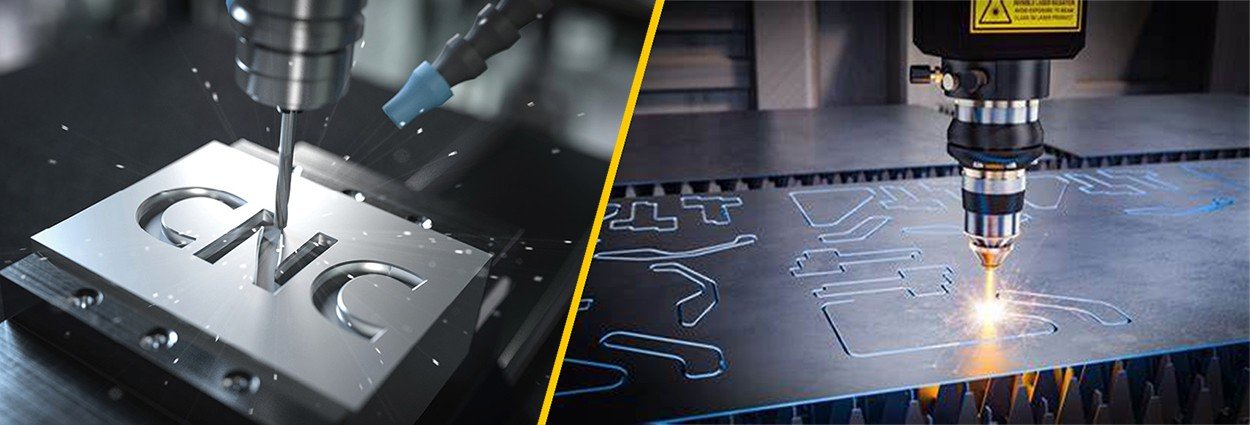

In the world of manufacturing and fabrication, choosing the right cutting method is crucial. Two popular options that often come under consideration are CNC (Computer Numerical Control) cutting and laser cutting. Each has its own set of unique characteristics, advantages, limitations, and ideal applications. Let's take a deep dive into the differences between these two cutting processes to help you make an informed decision for your next project.

Understanding CNC Cutting

CNC (Computer Numerical Control) Cutting is a subtractive manufacturing process. It involves using computer-controlled machines, such as mills or routers, to remove material from a workpiece. The machine follows a pre-programmed set of instructions to precisely cut, drill, or shape the material. These instructions are based on a 3D model or a 2D drawing of the final product. For example, in a CNC milling machine, a rotating cutting tool moves along multiple axes (usually three to five axes in common applications) to carve out the desired shape from a block of material, like wood, plastic, or metal.

How CNC Cutting Works?

The CNC Cutting process typically involves the following steps:

Design and Programming

An engineer or designer creates a detailed digital 3D model of the desired part using CAD (Computer-Aided Design) software. This model is then imported into CAM (Computer-Aided Manufacturing) software, where it is translated into G-code, a language understood by the CNC machine. The G-code instructs the machine on the toolpaths, cutting speeds, depths, and other parameters necessary to produce the desired shape.

Tool Selection and Setup

Depending on the material and the specific requirements of the project, the appropriate cutting tool, such as a drill bit, mill, or router bit, is selected and attached to the CNC machine. The workpiece is then securely mounted on the machine's table, and any necessary fixtures or clamps are positioned to ensure accurate positioning during cutting.

Cutting Process

Once the setup is complete, the CNC machine executes the programmed instructions with high precision. The cutting tool moves along the specified toolpaths, removing material layer by layer to create the desired shape. CNC machines can operate at various speeds and feed rates, allowing for optimal cutting conditions based on the material properties and the desired finish.

Benefits of CNC Cutting

Precision and Accuracy

CNC Cutting offers exceptional precision, with tolerances often measured in microns. This makes it ideal for applications where tight tolerances and high-quality finishes are required, such as in aerospace and medical device manufacturing.

Versatility

CNC machines can handle a wide range of materials, including metals, plastics, composites, and wood. They can also perform various cutting operations, such as milling, drilling, and engraving, making them suitable for diverse manufacturing requirements.

Reproducibility

Once a CNC program is created and verified, it can be easily replicated, ensuring consistent results across multiple production runs. This is particularly beneficial for mass production or when producing identical parts for assemblies.

Complex Geometries

With its ability to follow complex toolpaths, CNC Cutting can create intricate and complex shapes that would be difficult or impossible to achieve with traditional manual machining methods.

Limitations of CNC Cutting

Setup Time and Cost

The initial setup process for CNC Cutting, including creating the CAD/CAM design, selecting the right tools, and preparing the machine, can be time-consuming and may require specialized skills. This can increase the upfront cost, especially for small batch or prototype projects.

Material Waste

Depending on the material and the cutting process, CNC Cutting can generate significant material waste. For expensive materials, this can add to the overall cost per part.

Machine Size and Accessibility

CNC machines can be large and require significant floor space. This can be a limitation for facilities with limited workspace or when working on larger components that need to be machined in sections.

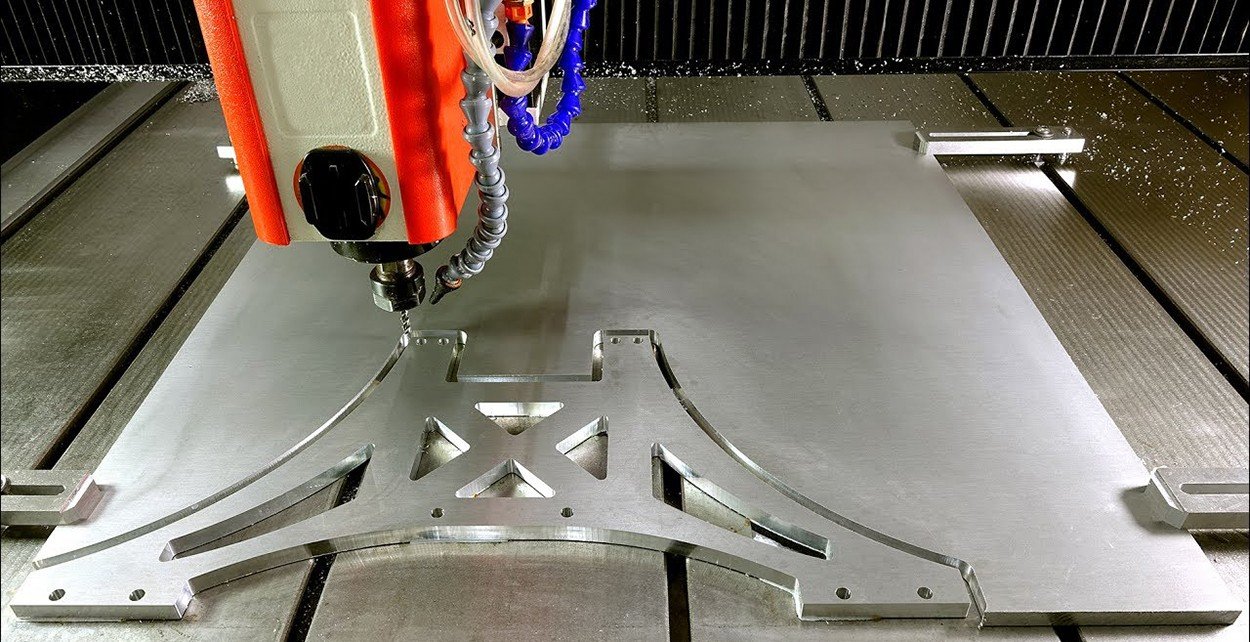

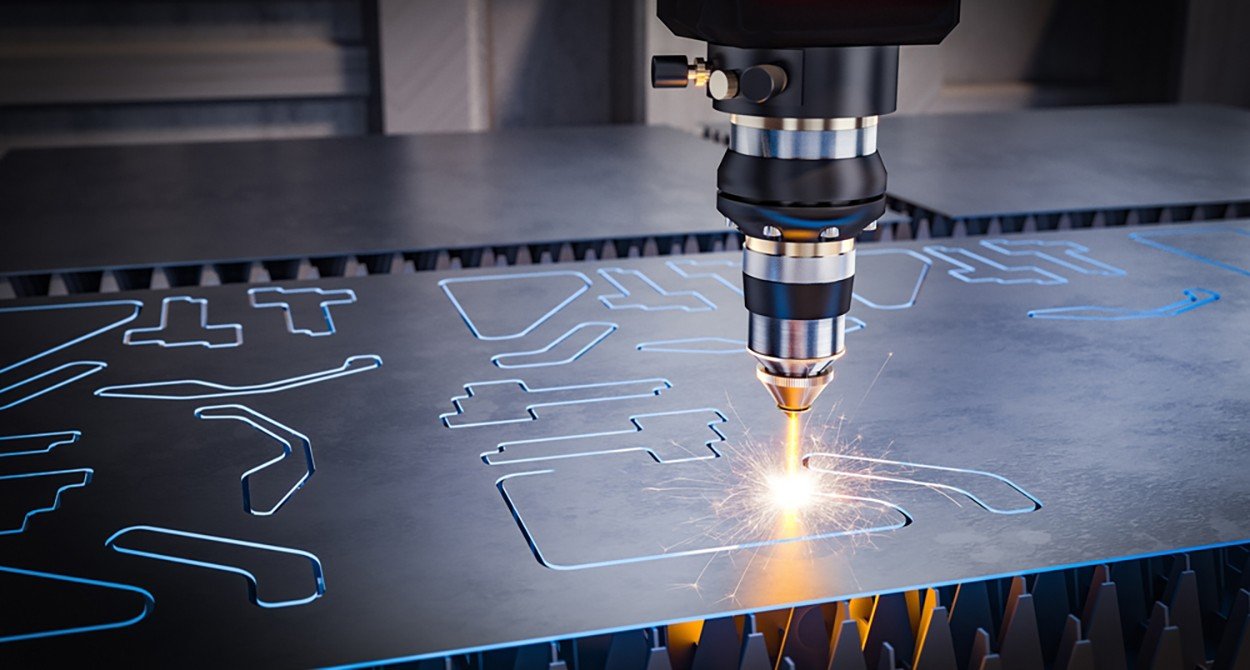

Understanding Laser Cutting

Laser cutting, on the other hand, is a thermal-based cutting process. It uses a high-powered laser beam to melt, burn, or vaporize the material being cut. The laser beam is directed onto the workpiece through a series of mirrors and lenses. As the laser beam hits the material, it heats the surface to a high temperature, causing it to quickly melt or vaporize. A stream of gas, such as oxygen or nitrogen, is then used to blow away the molten or vaporized material, leaving behind a clean cut. For example, in a CO₂ laser cutter, the laser beam is generated by exciting carbon dioxide gas, and this beam can be used to cut through materials like paper, fabric, acrylic, and even some thin metals.

How Laser Cutting Works?

The Laser Cutting process typically involves the following steps:

Material Preparation

The workpiece is placed on the cutting bed of the laser cutting machine, and any necessary clamping or fixation mechanisms are applied to ensure the material remains stable during the cutting process.

Laser Beam Generation and Focusing

A laser source generates a high-energy laser beam, which is then focused onto the surface of the material using lenses or mirrors. The focal point of the laser beam is adjusted to match the thickness and properties of the material being cut.

Cutting Process

The laser beam is directed along the desired cutting path, and as it interacts with the material, it causes rapid heating and vaporization or melting. A combination of gas, such as nitrogen or oxygen, is often used to assist in the cutting process, removing the molten or vaporized material and preventing it from re-solidifying or causing damage to the edges.

Control and Monitoring

The laser cutting machine is equipped with advanced software that controls the movement of the laser beam and monitors the cutting process. This allows for precise adjustment of parameters such as laser power, cutting speed, and focal position to achieve optimal cutting results.

Benefits of Laser Cutting

Extremely Precise and Clean Cuts

Laser Cutting can produce extremely sharp and smooth edges, with tolerances often reaching fractions of a millimeter. This makes it ideal for applications where precision and a high-quality finish are critical, such as in the manufacture of electronics, jewelry, and medical devices.

Minimal Material Waste

Since the laser beam focuses on a small area and cuts with such precision, there is minimal material loss during the cutting process. This can result in cost savings, especially when working with expensive materials.

No Mechanical Forces on the Workpiece

Unlike CNC Cutting, which requires physical contact between the cutting tool and the material, Laser Cutting is a non-contact process. This means there is no mechanical stress or deformation of the workpiece, which is beneficial for delicate or thin materials.

Versatility

Laser Cutting can be used on a wide variety of materials, including metals, plastics, composites, leather, and paper. It can also perform various operations, such as cutting, engraving, and marking.

Limitations of Laser Cutting

Material Compatibility and Thickness Restrictions

Different laser sources and machine configurations are suitable for different materials and thickness ranges. For example, high-power lasers may be required for cutting thick metals, but they may not be effective for very thin or delicate materials. Additionally, some materials, such as certain plastics, may produce harmful fumes during the laser cutting process, requiring proper ventilation and exhaust systems.

High Initial Investment and Operating Costs

Laser Cutting machines are generally more expensive to purchase and maintain compared to traditional CNC Cutting machines. The initial investment includes the cost of the laser source, optics, motion control systems, and safety features. Operating costs include energy consumption, laser maintenance, and replacement of optics.

Limited Strength in Thick Materials

While Laser Cutting can handle a wide range of material thicknesses, it may not be as effective as CNC Cutting for thick metals, where mechanical cutting forces are required to achieve the desired cut quality and material removal rate.

Comparing CNC Cutting and Laser Cutting

Now that we've explored the individual benefits and limitations of CNC Cutting and Laser Cutting, let's compare these two processes side by side:

| Feature | CNC Cutting | Laser Cutting |

Precision | Extremely high for complex geometries, with tolerances in microns | Extremely high for fine details and clean edges, tolerances in fractions of a millimeter |

Material Compatibility | Wide range, including metals, plastics, composites, and wood | Wide range, including metals, plastics, composites, leather, and paper, but may have restrictions based on laser source and material properties |

Complexity of Shapes | Can handle complex geometries with ease, following intricate toolpaths | Can handle complex shapes, especially those that benefit from a non-contact cutting process, but may have limitations with extremely thick or hard materials |

Cost | Higher setup costs and potential for material waste, but lower ongoing costs for large batches | Higher initial investment and operating costs, but lower material waste and good for prototyping and small batches |

Material Waste | Can generate significant waste depending on the cutting process and material | Minimal waste due to precise cutting technique |

Maintenance and Training | Requires skilled operators and regular maintenance of cutting tools | Requires trained technicians to maintain and operate the laser system, with potential costs for laser replacement and maintenance |

Conclusion

In conclusion, both CNC Cutting and Laser Cutting have their unique strengths and limitations. The choice between these two processes ultimately depends on the specific requirements of your project, including the material, design complexity, desired finish, and budget. If you require extremely precise cuts, the ability to handle complex geometries, and don't mind potentially higher setup costs and material waste, CNC Cutting may be the right choice. On the other hand, if you need extremely clean and precise edges, minimal material waste, and the flexibility to work with a wide range of materials, Laser Cutting could be the ideal solution.

By understanding the differences and similarities between CNC Cutting and Laser Cutting, you can make an informed decision that will ensure the success of your project. Whether you're a small business owner, a designer, or a manufacturer, taking the time to evaluate your options will help you achieve the best possible results for your specific manufacturing needs. So, before you start your next project, consider the benefits and limitations of each process carefully and choose the one that will best meet your requirements.

Article Navigation

Article Navigation

Industries

Foundries

-

March.18, 2025

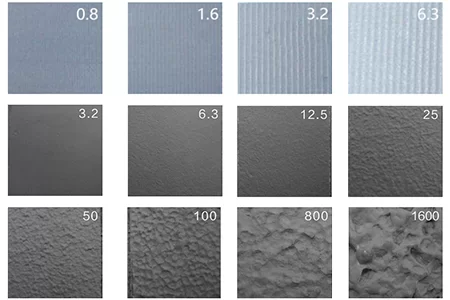

Surface Roughness Comparison of Castings with Different Materials and Processes

READ MORE

-

March.10, 2025

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

READ MORE

-

March.03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE

-

January.20, 2025

Surface Treatments for Metals After Casting

READ MORE

-

January.09, 2025

How to Select The Right Raw Materials for Casting Foundries?

READ MORE

-

December.09, 2024

Differences in Wax Materials for Precision Casting

READ MORE