CNC Machining vs. Metal Casting: Unraveling the Differences for Optimal Manufacturing

-

Home>

-

Blog>

-

Technology>

CNC Machining vs. Metal Casting: Unraveling the Differences for Optimal Manufacturing

When it comes to manufacturing, both CNC machining and metal casting are widely used to create complex metal parts. Each of these processes has distinct advantages and applications, but how do you decide which one is best suited for your project? In this blog, we’ll compare CNC machining and metal casting, highlighting their differences, benefits, and drawbacks, so you can make an informed decision that best meets your production needs.

What is CNC Machining?

CNC machining (Computer Numerical Control machining) refers to a manufacturing process that uses pre-programmed computer software to control machine tools such as drills, lathes, and mills. These machines remove material from a solid block (known as a billet) to create parts with high precision.

The CNC machining process is known for its accuracy and tight tolerances, and it works well for a variety of materials, including metals, plastics, and composites. This method is particularly effective for producing small to medium runs of highly detailed parts.

What is Metal Casting?

Metal casting, on the other hand, is a process where a molten metal is poured into a mold to take the shape of a desired part. The metal is allowed to cool and solidify before the mold is removed, revealing the finished part. Casting is ideal for producing parts that require complex shapes and large volumes.

There are various types of casting methods, including sand casting, investment casting, die casting, and permanent mold casting, each suitable for different applications and materials. Casting is commonly used for producing parts like engine blocks, structural components, and other large and complex items.

CNC Machining vs. Metal Casting: A Direct Comparison

Feature | CNC Machining | Metal Casting |

Precision | Extremely high precision and tight tolerances (±0.01mm). | Lower precision compared to CNC (typically ±0.1mm or more). |

Materials | Works with a wide range of materials, including metals, plastics, and composites. | Primarily used for metals such as aluminum, iron, steel, and bronze. |

Complexity | Ideal for parts with intricate details, sharp corners, and complex geometries. | Best suited for large parts or components with simpler geometries, but can also handle complex shapes. |

Cost | Expensive for small runs, high tooling costs. | Cost-effective for high-volume production, but expensive molds for low-volume runs. |

Lead Time | Shorter lead times for small batches and rapid prototyping. | Longer lead times due to mold creation and solidification times. |

Surface Finish | Smooth surface finish with minimal post-processing. | Surface finish may require additional work like grinding or polishing. |

Material Waste | Subtractive process, material waste can be significant. | Minimal waste compared to machining as the material is poured directly into the mold. |

Post-Processing | Minimal, depending on part complexity. | Often requires additional processes such as grinding, polishing, or machining. |

Design Flexibility | Very flexible in design changes and revisions. | Design changes can be expensive and time-consuming due to mold modifications. |

Advantages of CNC Machining

High Precision

CNC machining is unrivaled when it comes to accuracy. Parts are produced with tight tolerances and high-quality finishes, making CNC machining ideal for applications where precision is critical.

Versatility

CNC machines can process a variety of materials, including metals, plastics, and composites. This makes CNC machining suitable for diverse industries, from aerospace to medical devices to automotive components.

Shorter Lead Times

CNC machining is well-suited for rapid prototyping and small to medium-volume production. The lead time is typically faster compared to casting, especially for custom parts.

Lower Tooling Costs for Small Batches

The cost of tooling for CNC machining is usually lower than that for metal casting, especially for small runs. This makes it an attractive option for prototyping and low-volume production.

Advantages of Metal Casting

Cost-Effective for High Volumes

When it comes to high-volume production, metal casting is one of the most cost-effective methods. The initial mold creation is expensive, but once the mold is made, it can be used repeatedly to produce large quantities of parts at a low per-unit cost.

Complex Shapes

Casting is ideal for producing parts with complex geometries that would be difficult, if not impossible, to achieve with machining. This makes it a popular choice for items such as engine blocks, automotive parts, and large structural components.

Minimal Material Waste

Unlike CNC machining, which is a subtractive process, casting involves pouring molten metal into a mold, minimizing material waste. This is particularly beneficial when using expensive metals or alloys.

Variety of Materials

Metal casting can handle a wide range of materials, including aluminum, steel, iron, and bronze, making it a versatile choice for producing durable parts.

Limitations of CNC Machining

Despite its many advantages, CNC machining has some limitations:

Material Waste

CNC machining is a subtractive process, meaning material is removed from a solid block to create a part. This can result in significant material waste, especially for large or complex parts.

Higher Costs for Large Parts

CNC machining can be costly for producing large parts due to the machining time required and the wear on tools. The larger the part, the more expensive the process becomes.

Not Ideal for High-Volume Production

CNC machining is not as cost-effective as casting when it comes to large-volume production. The tooling and machine time required make it more suitable for smaller runs.

Limitations of Metal Casting

Although metal casting is widely used, it comes with its own set of limitations:

Lower Precision

Metal casting generally offers lower precision than CNC machining. While it’s great for large parts or those with less intricate details, casting may require additional finishing to achieve the desired level of accuracy.

High Initial Tooling Costs

Creating molds for casting can be expensive, particularly for custom parts or low-volume runs. This can make casting less cost-effective for small batches.

Post-Casting Processes

After casting, parts may need additional processes such as grinding, polishing, or machining to remove excess material or improve surface finish.

Conclusion: Which Process Should You Choose?

Ultimately, the choice between CNC machining and metal casting depends on your specific project needs:

If you need high precision and tight tolerances, CNC machining is likely your best option. It’s ideal for small to medium runs, prototypes, and parts with complex features.

On the other hand, if you’re looking for a cost-effective solution for large-volume production of complex parts, metal casting may be the better choice. It’s perfect for parts that need to be produced in large quantities and for complex shapes that would be hard to achieve through machining.

By understanding the unique advantages and limitations of both processes, you can make an informed decision that aligns with both your production needs and your budget.

At Hulk Metal, we specialize in providing high-quality CNC machining and casting parts tailored to your specific requirements. Whether you're looking for precision CNC parts or robust casting solutions, we are here to help. Simply provide us with your drawings or samples, and our expert engineers will develop reliable, cost-effective solutions that meet your exact needs. Reach out today to get started with your next project!

Article Navigation

Article Navigation

Industries

Foundries

-

March.18, 2025

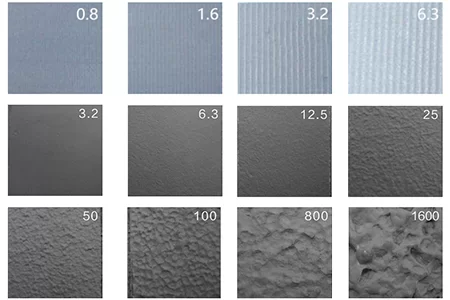

Surface Roughness Comparison of Castings with Different Materials and Processes

READ MORE

-

March.10, 2025

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

READ MORE

-

March.03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE

-

January.20, 2025

Surface Treatments for Metals After Casting

READ MORE

-

January.09, 2025

How to Select The Right Raw Materials for Casting Foundries?

READ MORE

-

December.09, 2024

Differences in Wax Materials for Precision Casting

READ MORE