The Critical Role of Casting Molds in High-Quality Foundry Solutions

-

Home>

-

Blog>

-

Technology>

Precision Begins with the Mold: The Critical Role of Casting Molds in High-Quality Foundry Solutions

In the world of metal casting, the mold is where precision takes shape. Whether you're producing complex industrial components, high-strength automotive parts, or intricate architectural castings, the casting mold is the heart of the entire manufacturing process. At the core of every high-performance casting lies a mold that is engineered with accuracy, durability, and efficiency in mind.

The Foundation of Superior Castings

Casting molds - whether permanent, expendable, or semi-permanent - serve as the blueprint that defines the geometry, surface finish, and internal integrity of the final product. A well-designed mold ensures dimensional consistency, reduces material waste, and minimizes post-processing. Conversely, poor mold design can lead to defects such as porosity, shrinkage, and uneven cooling, compromising both function and appearance.

That's why foundry professionals understand: investing in high-quality molds is not a luxury - it's a necessity.

Tailored Mold Solutions for Diverse Casting Methods

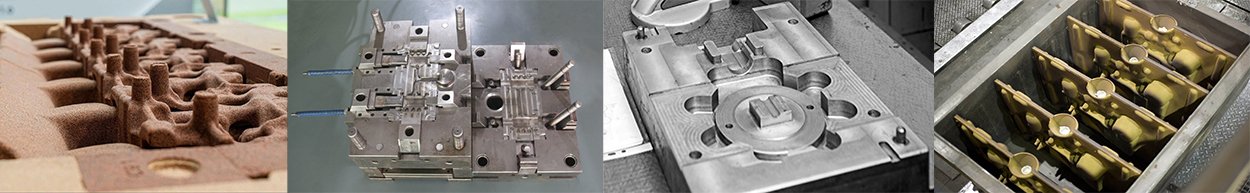

At our foundry, we offer end-to-end casting services that include expert mold design and manufacturing, tailored to various casting techniques such as:

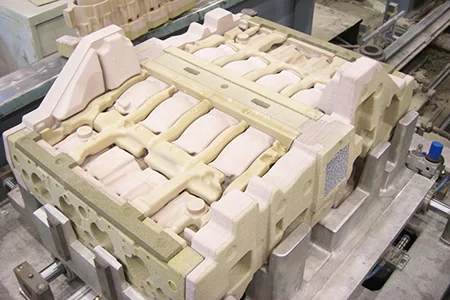

Sand Casting: Ideal for large or complex parts, our resin-bonded and green sand molds deliver cost-effective results while maintaining high dimensional accuracy.

Die Casting: We utilize precision-machined steel molds capable of withstanding high pressures, ideal for aluminum, zinc, and magnesium alloys.

Investment Casting (Lost Wax): With ceramic molds built around detailed wax patterns, this method enables the production of high-precision, thin-walled components.

Shell Molding: Our thermoset resin-coated sand molds offer excellent surface finish and dimensional repeatability, perfect for small to medium-sized parts.

Each casting mold is developed with a deep understanding of thermal behavior, alloy characteristics, and solidification patterns - ensuring that every part we produce meets the highest metallurgical and mechanical standards.

Advanced Mold Manufacturing Capabilities

Our mold production integrates CNC machining, 3D modeling, and CAD/CAM technologies to create precise tooling for even the most complex geometries. We can work from your 2D drawings, 3D files, or physical samples to develop robust mold solutions that align with your production goals. Our capabilities include:

√ Steel and aluminum permanent molds

√ Shell core boxes and tooling

√ High-pressure die-cast molds

√ Rapid prototyping for test runs and sample validation

√ Maintenance and repair services for long-life molds

By maintaining tight tolerances and optimizing gating and venting systems, we minimize defects and shorten cycle times—delivering cost-effective solutions without compromising on quality.

Quality Assurance Built Into Every Mold

All our mold designs undergo thorough simulation and validation processes using casting simulation software. This allows us to identify potential hotspots, predict shrinkage patterns, and fine-tune runner systems before physical production begins. Once manufactured, each mold is inspected for dimensional accuracy, structural integrity, and surface finish.

We are proud to offer molds that not only meet international quality standards but are also tailored for ease of maintenance and longevity in high-volume production environments.

Your Trusted Partner for Custom Casting Molds

As an experienced metal casting service provider, we understand that every project has unique requirements. Our engineers collaborate closely with clients to design molds that deliver optimal performance - whether you're launching a new product or improving an existing casting line.

We serve a broad range of industries including:

√ Automotive and transportation

√ Oil & gas and petrochemical

√ Agricultural machinery

√ Construction and infrastructure

√ Marine and rail components

Our flexible production system and global logistics network enable fast turnaround times, competitive pricing, and consistent delivery - making us a reliable partner in your supply chain.

Why Choose Us?

√ Decades of foundry experience in casting mold design and production

√ Advanced mold-making equipment and expert technical support

√ Comprehensive casting services from mold design to finished part

√ Customization available for various alloys and casting processes

√ Commitment to quality, durability, and customer satisfaction

Partner with Hulk Metal - Your Reliable Casting Mold Expert

At Hulk Metal, we understand that the quality of your casting starts long before molten metal touches the mold. That's why we bring decades of expertise, advanced tooling capabilities, and a customer-first mindset to every mold we design and manufacture.

Whether you're launching a new product line or optimizing an existing component, our team is ready to provide customized mold solutions that ensure precision, efficiency, and long-term performance. From CAD design and mold prototyping to full-scale production and post-casting services, Hulk Metal is your one-stop partner for high-quality casting and mold manufacturing.

With a global customer base and a reputation built on trust, consistency, and technical excellence, Hulk Metal is committed to helping your business cast stronger, smarter, and faster.

Ready to bring your casting vision to life?

Reach out to Hulk Metal today - let's shape success together.

Article Navigation

Article Navigation

Industries

Foundries

-

May.23, 2025

Casting Molds: The Heart of Precision Casting

READ MORE

-

May.20, 2025

Something You Need to Know About Sheet Metal Fabrication

READ MORE

-

April.23, 2025

How to Find A Cost-Efficient Metal Casting Manufacturer?

READ MORE

-

March.28, 2025

Everything You Need to Know About Die Casting!

READ MORE

-

March.26, 2025

Sand Casting vs. Die Casting: Which is Right for Your Project?

READ MORE