Only by becoming a better foundry and mastering more metal casting technologies can we provide higher-quality metal casting services. HULK Metal has been doing this.

HULK Metal

Top Metal Casting Service Supplier

-

Home>

-

Metal Casting>

-

Advantages

-

Capacities

-

Processes

-

Industries

-

Types

-

Introduction

-

Articles

-

Review

-

Top

START METAL CASTING SERVICE at HULK METAL

To provide excellent metal casting services, we continuously improve our capabilities from the following four aspects to provide excellent metal casting services. We will accompany you to grow continually and become the best in our respective industries.

-

Foundry:

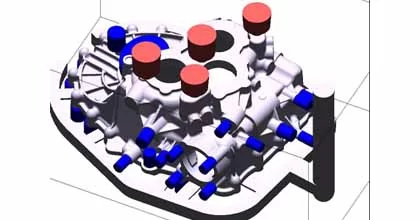

HULK Metal conducts three-dimensional resource integration horizontally (casting types) and vertically (mold manufacturing, casting, precision CNC machining, quality control, and packaging). This allows us to choose a better casting process to complete the order with quality and quantity according to the drawings. A vertical supply chain lets us deliver orders to you faster and at a lower cost.

-

Experience:

As of today, we have provided metal casting services to dozens of industries and hundreds of companies, and they have all chosen to place orders with us again and again. We believe that as long as we provide better services and better complete their orders, we can gain their recognition. It turns out we were right.

-

Quality:

Quality refers not only to the order but also to our service. For orders, our quality control center will develop a quality inspection plan based on your requirements and issue material and product testing reports. For services, we have a series of service standards. Every customer can make suggestions when they are not satisfied, and we will treat every suggestion as a step towards progress.

-

Service:

We aim to provide better metal casting solutions to more customers, reduce the cost of orders to lower, shorten lead times, and even achieve faster delivery. We also hope to save you time and energy through thoughtful services such as online factory visits, production progress feedback, etc. You could give us the drawings and required quantities and let us help you develop a better production solution.

METAL CASTING SERVICE CAPACITIES

Here are the casting services we can provide you, introduced in terms of materials, process, piece weight, production capacity, certification, and finishing capabilities. You can consult our engineers for more details.

MANUFACTURING: | According To the Drawings and Samples |

SERVICE METHOD: | OEM |

MATERIALS:

| Ductile Iron, Malleable Iron, Gray Iron, Carbon Steel, Stainless Steel, Brass, Aluminum Alloy Steel |

PROCESS: | Sand Casting, Investment Casting, Die Casting, Lost Foam Casting |

WEIGHT: | <=2 Tons/piece |

PRODUCTION CAPACITY: | 500 tons/month |

CERTIFICATION: | ISO 9001, IATF 16949 |

FINISHING: | Heat Treatment, CNC Machining, Surface Treatment |

MOQ: | 500KG / A Standard Tray |

HOW YOUR METAL CASTING PARTS PRODUCED

Here's how your metal casting order is produced and delivered. If you want to know more about the metal casting service process, you can contact our online engineers, who will explain it in detail.

-

01

Customize Solutions

We will develop a solution based on your drawings and requirements and calculate the price. After the order is confirmed, mold-making and sample production will begin.

-

02

Mold Making

For sand casting, we make sand cores and make sand moldle manually or mechanically. For investment casting, we first make the mold to produce the wax pattern. For die-casting, we make metal die-casting molds.

-

03

Metal Smelting

Use a crucible to heat and melt the metal and add the other metals sequentially at the appropriate time. In this way, liquid metals with different casting properties can be obtained. We use eddy current electric heating because it is more environmentally friendly.

-

04

Pouring

Pour the liquid metal into the mold that has been made (die casting is to press the liquid aluminum alloy into the metal cavity). There are two ways of pouring mechanical automatic and manual. It is cheaper to use automatic pouring for large orders, while manual methods can be selected for small orders.

-

05

Cleaning and Recycling

After the mold is cooled, we need to separate the mold from the metal casting and recover the reusable material to save costs. Metal castings need to cut off the excess parts. If it is a tree-forming mold, we need to cut castings down, and then the residue on the surface should be removed by shot blasting and other treatments.

-

06

Finishing

Use CNC machining to adjust the castings' shape further to achieve the shape and tolerance required by the customer. The processes usually required include turning, milling, tapping, drilling, etc. CNC machined castings may also require surface treatments such as galvanizing and powder coating if required.

-

07

Quality Control

We will complete the inspection of the castings' shape, size, surface roughness, hardness, ductility, brittleness, and other aspects according to requirements and issue material and product testing reports.

-

08

Packaging & Delivery

We provide wooden boxes, cardboard boxes, and other packaging materials boxes. Styrofoam and bubble paper are used to fill between products. We can also customize according to customers' requirements. Find better freight companies for faster delivery by the freight consulting services we provide.

-

09

After Service

We will provide comprehensive after-sales service to ensure the overall quality of the order. We hope that our customers will provide valuable feedback on our services, which is the source of our continuous improvement.

INDUSTRIES HULK METAL FOUNDRY SERVED

This module will introduce you to some of the industries we have served. Almost all industries will use metal casting services to produce some accessories. So, no matter what your industry is, you can send us drawings or sample pictures and let our engineers provide a complete production solution and a better quotation.

-

Agricultural Machinery Parts

Agricultural Machinery PartsThe manufacturing of Agricultural Machinery includes parts manufacturing and assembly. The processes required for parts manufacturing include casting and forging, stamping, heat treatment, machining, surface treatment, etc. For casting, selecting the appropriate process according to the shape, size, surface accuracy, and other requirements of agricultural machinery parts can save costs and time.

READ MORE

-

Food Processing Equipment Parts

Food Processing Equipment PartsHULK Metal has provided parts OEM services to dozens of well-known food machinery manufacturers. At present, we have used sand casting, investment casting, and die casting to produce food machinery accessories made of food-grade aluminum, iron, carbon steel, stainless steel, and other materials. Kindly contact our engineers for details.

READ MORE

-

Mining Machinery Parts

Mining Machinery PartsComplete production solutions, advanced metal foundries, strict management, and quality inspection processes allow customers to receive mining machinery parts with guaranteed quality and quantity more quickly while enjoying more thoughtful services.

READ MORE

More Results

METAL CASTING TYPES HULK METAL CAN SUPPLY

Here, we will introduce the types of metal casting services we can provide in detail, such as sand casting, investment casting, die casting, and some material-related casting services. You can click to learn more according to your needs.

Sand Casting Service

Investment Casting Service

Aluminum Casting Service

Lost Foam Casting Service

-

Sand Casting Service

Sand casting service is a process in which foundries use siliceous sand, zircon sand, chromite sand, etc., and clay, silica sol, and water glass as binders to make molds and complete the production of metal castings. Sand casting has more ways to produce orders. The castings are bigger, and the price is lower, but the castings' surface roughness and precision are lower than other casting processes. Whether casting is suitable for sand casting production requires consideration of the characteristics and requirements of the workpiece itself, so a professional metal service foundry will select a more suitable casting process based on your drawings and requirements to develop a solution and complete the order.

-

Investment Casting Service

Investment casting service is a process in which a foundry uses wax patterns to complete metal casting orders through tree assembly, dipping, powder coating, air drying, melting wax, roasting, casting liquid metal, shelling, finishing, and other processes. Castings produced by investment casting have smaller Ra values and higher precision than sand casting. However, the process is more complex and can produce castings with smaller weights and relatively higher cost. We can decide whether to use investment casting to complete the order according to the castings' requirements. We can develop solutions, calculate prices, and complete the production and delivery of orders for you.

-

Aluminum Casting Service

Aluminum casting services are a process in which foundries process aluminum and its alloys into castings of specific shapes, sizes, and properties using sand casting, investment casting, gravity casting, and other processes. Because it involves mass production, the entire process can improve production efficiency, shorten lead time, increase the qualification rate of aluminum castings, and reduce production costs after being better optimized. Therefore, a good aluminum casting service provider needs to be familiar with various processes and be able to give better solutions.

-

Lost Foam Casting Service

Lost foam casting uses foam plastic to make a casting model. After applying refractory material, use a vibration table to complete the mold without taking the model out. The metal pouring is completed under negative pressure, followed by cooling, cleaning, and finishing to complete the casting process.

METAL CASTING SERVICE INTRODUCTION

Here, we will show some content about Metal Casting, such as what it is, its advantages and disadvantages, and what you will gain if you select us as a partner. Contact us now, and Our Engineer will calculate a better price according to your orders.

-

Metal Casting Means:

Metal casting is the process of making metal parts by pouring molten metal into a mold with the desired shape. We can make molds from various materials, such as sand, plaster, ceramic, or metal. After the metal has cooled and solidified, remove the casting. Metal casting can produce complex and large parts that would be difficult or costly to manufacture by other methods. Metal casting has been widely used, and we can see metal castings everywhere.

-

Advantages and Disadvantages of Metal Casting:

Advantages:

1. Can make parts with complex designs with intricate detail. 2. Can make large parts. 3. Fewer steps than other manufacturing processes. 4.Can make most of metal parts.

Disadvantages:

1. Limited by the process, there will be pores inside the casting. 2. The production cycle will be longer than other processes. 3. Unable to cast smaller and more precise metal pieces.

What You Will Get When Choose Our Metal Casting Service.

We have a professional quality inspection team and quality assurance services to ensure that the order qualification rate meets your requirements. Achieve shorter lead time and lower production costs by optimizing the production process. You receive your goods faster with our supply chain. Contact us now, and let our engineers help you formulate a suitable solution and calculate a better price.

HULK Metal also manufactures standardized products such as handrails and guardrails systems, concrete precast accessories, glass clamps, and aluminum-plastic panels.

ARTICLE OF METAL CASTING SERVICE

Here, we compile articles about metal casting in our continuous learning and progress. They have raw materials, casting types, Casting process flows, and their advantages and disadvantages. You can learn more about metal casting and our services here.

-

March 18, 2025

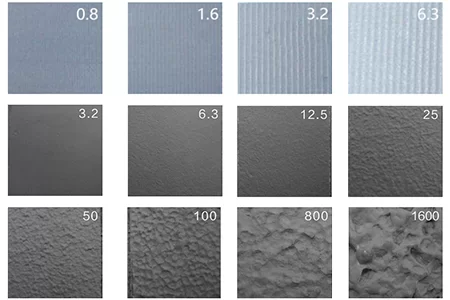

Surface Roughness Comparison of Castings with Different Materials and Processes

READ MORE

-

March 12, 2025

Applications of Stainless Steel Castings in Medical Devices

READ MORE

-

March 10, 2025

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

READ MORE

-

March 03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE

-

February 25, 2025

How to Compare Product Quality Between Different Casting Foundries?

READ MORE

-

January 09, 2025

How to Select The Right Raw Materials for Casting Foundries?

READ MORE