Casting Defects and Their Control Methods

-

Home>

-

Blog>

-

Technology>

Casting Defects and Their Control Methods

Castings are prone to various defects during the production process. The formation of these defects is often caused by the combined action of multiple factors, including casting process, alloy characteristics, smelting quality, molding material performance, etc. For different defects, a comprehensive analysis must be conducted based on defect characteristics, location, use process, sand type and other factors in order to take effective control measures to improve casting quality. Here, Hulk Metal, as a professional casting foundry, summarizes some common casting defects and their control methods, hoping to help everyone!

Misrun

The casting is partially defective, often in the thin-walled part, the part farthest from the pouring channel or the upper part of the casting. The defective corners are smooth and bright and do not stick to sand.

Causes

Pouring temperature is low, pouring speed is too slow or pouring is intermittent;

The cross-section area of the horizontal runner and the inner runner is small;

The carbon and silicon content in the molten iron is too low;

The water content and coal powder in the molding sand are too much, the gas emission is large, or the mud content is too high, and the air permeability is poor;

The height of the upper sand mold is not enough, and the molten iron pressure is insufficient.

Prevention Methods

Increase the pouring temperature, speed up the pouring speed, and prevent intermittent pouring;

Increase the cross-section area of the horizontal runner and the inner runner;

Adjust the post-furnace batching to appropriately increase the carbon and silicon content;

Strengthen the exhaust in the casting mold, reduce the coal powder in the molding sand, and the amount of organic matter added;

Increase the height of the upper sand box.

Short Pouring

The upper part of the casting is incomplete, the horizontal plane of the molten iron in the sprue is flush with the horizontal plane of the molten iron in the casting, and the edge is slightly rounded.

Causes

Insufficient molten iron in the ladle;

The sprue is narrow and the pouring speed is too fast. When the molten iron overflows from the pouring cup, the operator mistakenly thinks that the mold is full and stops pouring too early.

Prevention Methods

Correctly estimate the amount of molten iron in the ladle;

For molds with narrow sprues, appropriately slow down the pouring speed to ensure that the mold is full.

Damage/Fracture of Castings

Causes

The castings are too violently sanded, or the castings are damaged by collision during transportation;

During drum cleaning, the castings are improperly loaded, and the weak parts of the castings are broken during rolling;

The cross-sectional dimensions of the riser and riser neck are too large; the riser neck does not have a knock-out surface (groove). Or the method of knocking out the pouring riser is incorrect, causing damage to the casting body.

Prevention Methods

When cleaning and transporting the castings, pay attention to avoid various forms of excessive collision and vibration, and avoid unreasonable dropping;

During drum cleaning, strictly follow the process regulations and requirements;

Modify the dimensions of the riser and riser neck, make the riser neck knock-out surface, and correctly grasp the direction of the pouring riser.

Sand Sticking & Rough Surface

Sand sticking is a surface defect of castings, which is manifested by sand particles that are difficult to remove adhering to the surface of the castings; if the castings have uneven and non-smooth surfaces after the sand particles are removed, it is called surface roughness.

Causes

Sand particles are too coarse and the sand mold is not compact enough;

The water content in the molding sand is too high, making the molding sand difficult to compact;

The pouring speed is too fast, the pressure is too high, and the temperature is too high;

Too little coal powder in the molding sand;

The template baking temperature is too high, causing the surface molding sand to dry; or the template baking temperature is too low, and the molding sand adheres to the template.

Prevention Methods

Use finer raw sand when the air permeability is sufficient, and appropriately increase the compactness of the molding sand;

Ensure a stable effective coal powder content in the molding sand;

Strictly control the water content of the sand;

Improve the pouring system, improve the pouring operation, and reduce the pouring temperature;

Control the template baking temperature, which is generally equal to or slightly higher than the molding sand temperature.

Sand Holes

Hole filled with molding sand inside or on the surface of the casting.

Causes

The surface strength of the molding sand is not enough;

The pattern has no fillet or the draft angle is small, resulting in sand hooking, and the mold is damaged but not repaired or the mold is assembled before repair;

The sand mold is placed for too long before pouring, and the surface strength decreases after air drying;

The mold is damaged during assembling or transportation;

The floating sand in the mold is not cleaned up when assembling, and the pouring cup is not covered after assembling, and broken sand falls into the mold.

Prevention Methods

Increase the clay content in the molding sand, add new sand in time, and improve the surface strength of the molding sand;

The pattern should have high finish, and the draft angle and casting fillet should be reasonably made. The damaged mold should be repaired before assembling;

Shorten the placement time of the sand mold before pouring;

Be careful when assembling or transporting the mold to avoid damage or sand particles falling into the sand mold cavity;

Clear the floating sand in the mold before assembling, and cover the pouring mouth.

Burrs & Sand Expansion

The burr often appears at the parting surface of the casting. It is a thin sheet of metal protrusions perpendicular to the surface of the casting and with uneven thickness. The sand expansion is the local expansion of the inner and outer surfaces of the casting, forming irregular nodular metal protrusions.

Causes

Insufficient or uneven compactness;

Insufficient strength of the surface sand, or too high water content of the molding sand;

The liquid metal pressure head is too large, and the pouring speed is too fast.

Prevention Methods

Increase the compactness of the mold and avoid local looseness;

Adjust the sand mixing process, control the water content, and improve the strength of the molding sand;

Reduce the pressure head of the liquid metal and reduce the pouring speed.

Lifting The Box

The casting has a large area of seam at the parting surface, which changes the outer dimensions of the casting. Lifting the box vigorously causes fire leakage - the molten iron overflows from the parting surface, which causes insufficient pouring defects in severe cases.

Causes

The sand box is not tightened, the weight is not good enough or the weight is removed too early;

Pouring too fast, the impact force is too large;

The template is bent.

Prevention Methods

Increase the weight of the weight, and remove the weight after the molten iron solidifies;

Lower the position of the ladle and reduce the pouring speed;

Correct the template.

Sand Dropping

The blocky metal protrusions on the surface of the casting are very similar in appearance to the fallen sand blocks. In other parts of the casting, sand holes or defects often appear.

Causes

There are deep and small grooves on the pattern, which are the same as the structural features or the draft angle is small, and the sand mold is damaged or cracked when the mold is removed;

The compactness is uneven and the local strength of the mold is insufficient;

When the mold is assembled and transported, the sand blocks of the mold are accidentally dropped.

Prevention Methods

The draft angle of the pattern should be appropriate and the surface should be smooth;

The compactness of the mold is high and uniform;

Be careful when assembling and transporting.

Misalignment

One part of the casting is misaligned with the other part at the joint of the parting surface, resulting in relative displacement, so that the shape of the casting does not conform to the drawing.

Causes

Poor pattern making, misalignment of the upper and lower molds or deformation of the pattern;

Inaccurate positioning of the sand box or template, or loose positioning pins;

Wear of parts on the extrusion molding machine, such as wear of the lower lining plate of the positive pressure plate and the bearing of the reverse pressure plate;

Deformation of the sleeve used for pouring, carelessness during transportation and surrounding the box, causing displacement of the upper and lower castings.

Prevention Methods

Strengthen the inspection and repair of the template;

Frequently check the positioning pins and pin holes of the sand box and template, and install them reasonably;

Check the relevant parts of the extrusion molding machine, adjust them in time, and replace them if they are worn out;

Regularly reshape the sleeve. Be careful when transporting the casting mold after removing the box. For the sand mold poured on the surface, a row of sand molds should be surrounded by a row.

Gray-black Fracture & Spots

The fracture of the casting is gray-black or has small black spots, more in the center and less on the edge. Flake graphite can be seen in metallographic observation.

Causes

The chemical composition of the molten iron does not meet the requirements, and the carbon and silicon content is too high;

The bismuth inoculated in front of the furnace is added to the ladle too early or too late, or the amount of bismuth is insufficient.

Prevention Methods

Correctly select the chemical composition and reasonably mix the ingredients to keep the carbon and silicon content in the molten iron within the specified range;

Increase the amount of bismuth added and strictly follow the inoculation process in front of the furnace.

Cracks (hot cracks, cold cracks)

There are penetrating or non-penetrating cracks on the outside or inside of the casting. Hot cracks have dark or black oxidized surfaces with tortuous fracture shapes. Cold cracks are relatively clean brittle cracks with flat fractures and metallic luster or slight oxidized color.

Causes

The carbon and silicon content in the molten iron is too low, and the sulfur content is too high;

The pouring temperature is too high;

The riser neck is too large or too short, causing serious local overheating, or the weight is too small, and the shrinkage compensation is not good;

The casting is subjected to excessive impact during cleaning and transportation.

Prevention Methods

Control the chemical composition of the molten iron within the specified range;

Reduce the pouring temperature;

Reasonably design the riser system;

Avoid excessive impact on the casting during cleaning and transportation.

Pores

The pores are smooth and bright, with round, pear-shaped and needle-shaped shapes. The sizes of the pores vary, and they are produced on the surface or inside the casting. The pores inside the casting can only be found after it is broken or machined.

Causes

The small furnace charge is damp, severely rusted or has oil stains, which makes the molten iron contain too much gas and is severely oxidized;

The tap hole, tap trough, furnace lining, and ladle lining are not dry;

The pouring temperature is low, so that the gas does not have time to float up and escape;

The aluminum content in the furnace charge is high, which is easy to cause hydrogen pores;

The sand mold has poor air permeability, high moisture content in the molding sand, and contains more coal powder or organic matter, which makes a large amount of gas generated during pouring and difficult to discharge.

Prevention Methods

The furnace charge should be properly managed and the surface should be clean;

The furnace cylinder, front furnace, tap hole, tap trough, and ladle must be dried;

Increase the pouring temperature;

Do not use scrap steel with too high aluminum content;

Appropriately reduce the moisture content of the molding sand, control the amount of coal powder added, and pierce the pores, etc.

Shrinkage/Porosity

Dispersed, fine shrinkage cavities with dendrites are called shrinkage cavities, and those finer than shrinkage cavities are called porosity. They often appear in hot areas.

Causes

The carbon and silicon content in the molten iron is too low, resulting in large shrinkage;

The pouring speed is too fast and the pouring temperature is too high, resulting in large liquid shrinkage;

The pouring system and riser are improperly designed, and sequential solidification cannot be achieved;

The riser is too small, resulting in insufficient shrinkage compensation.

Prevention Methods

Control the chemical composition of the molten iron within the specified range;

Reduce the pouring speed and pouring temperature;

Improve the pouring and riser system and use sequential solidification;

Increase the volume of the riser to ensure sufficient shrinkage compensation.

White Cast Iron

White cast iron structure appears inside the fracture of the casting, and gray cast iron appears on the edge.

Causes

Molten iron with high carbon and silicon content has too high hydrogen content;

Too much white cast iron forming elements such as chromium are brought into the charge;

Element segregation is serious;

Prevention Methods

Control the chemical composition, carbon and silicon content should not be too high;

Furnace lining and ladle lining should be dried; The moisture content of the molding sand should not be too high;

Strengthen the charge management to reduce the introduction of white cast iron elements.

Conclusion

There are many types of casting defects, but with proper raw material management, optimized process parameters, and strict quality control, these issues can be effectively minimized or eliminated - greatly improving casting performance and service life.

Hulk Metal - Your Trusted Professional Casting Manufacturer

Hulk Metal focuses on the design, manufacture and quality control of high-quality castings. We are equipped with advanced smelting, testing and analysis equipment, and our experienced process team can customize defect control solutions for you. Whether it is gray iron castings with complex structures or high-strength ductile iron or steel parts, we can achieve high-standard production delivery.

Choose Hulk Metal to make casting more accurate and reliable!

To learn more about casting process control and quality solutions, please view other articles on our official website or contact the engineering team directly!

Article Navigation

Article Navigation

Industries

Foundries

-

May.23, 2025

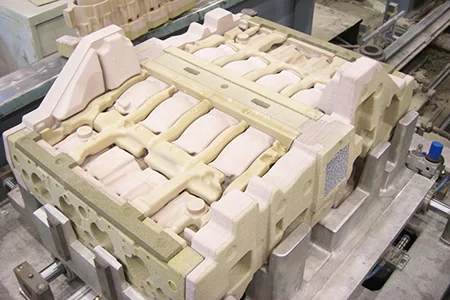

Casting Molds: The Heart of Precision Casting

READ MORE

-

April.23, 2025

How to Find A Cost-Efficient Metal Casting Manufacturer?

READ MORE

-

March.28, 2025

Everything You Need to Know About Die Casting!

READ MORE

-

March.26, 2025

Sand Casting vs. Die Casting: Which is Right for Your Project?

READ MORE

-

March.03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE