How Much Do You Know About the Types of Metal Casting Processes?

-

Home>

-

Blog>

-

Technology>

How Much Do You Know About the Types of Metal Casting Processes?

Metal casting is one of the oldest manufacturing methods known to humanity, with roots stretching back over 5,000 years. Despite its ancient origins, metal casting remains a cornerstone of modern manufacturing. From small, intricate components used in electronics to large, complex parts in automotive and aerospace industries, metal casting offers unmatched versatility and cost-efficiency.

Understanding the different types of metal casting processes is crucial for manufacturers, engineers, and procurement teams alike - especially when choosing a metal casting service that aligns with performance requirements, production volume, budget, and material specifications. In this guide, we'll explore the major casting processes, their advantages and disadvantages, typical applications, and considerations when selecting the right casting method for your project.

The Fundamentals of Metal Casting

At its core, metal casting is the process of melting metal, pouring it into a mold cavity, and allowing it to solidify. Once solid, the metal part, known as a casting, is ejected or broken out of the mold. This seemingly simple process encompasses a wide range of techniques, each with its own set of advantages, limitations, and ideal applications.

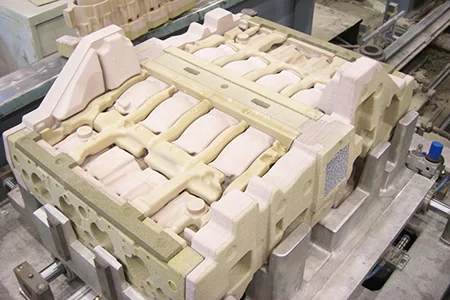

Sand Casting - The Workhorse of Metal Casting

Overview

Sand casting is the most widely used metal casting process globally. It involves packing sand around a pattern of the desired part, creating a mold into which molten metal is poured. After cooling, the sand mold is broken apart to reveal the final casting.

Advantages

√ Ideal for large and heavy parts

√ Suitable for both ferrous and non-ferrous metals

√ Cost-effective for low and medium production runs

√ Short lead times

Limitations

√ Lower surface finish and dimensional accuracy compared to other methods

√ Post-processing often required

Common Applications

Automotive engine blocks, pump housings, cylinder heads, large machinery parts.

Investment Casting - Precision and Complexity

Overview

Also known as lost-wax casting, investment casting uses a wax pattern coated with refractory ceramic material to form a mold. Once the ceramic hardens, the wax is melted away, and molten metal is poured into the cavity.

Advantages

√ Exceptional surface finish and dimensional accuracy

√ Capable of casting complex geometries and thin walls

√ Minimal post-processing required

Limitations

√ Higher cost due to mold preparation

√ Longer lead times

Common Applications

Aerospace components, medical devices, turbine blades, firearms, jewelry.

Die Casting - High-Speed, High-Volume Production

Overview

Die casting involves forcing molten metal under high pressure into reusable steel molds (dies). It's most suitable for non-ferrous metals like aluminum, zinc, and magnesium.

Advantages

√ Excellent dimensional accuracy and surface finish

√ High production rates and repeatability

√ Little to no machining required

Limitations

√ High tooling and setup costs

√ Limited to non-ferrous metals

√ Not suitable for large or very thick parts

Common Applications

Automobile components, electronic housings, appliance parts, consumer electronics.

Permanent Mold Casting - Balancing Quality and Efficiency

Overview

In permanent mold casting, reusable metal molds are used instead of expendable molds like sand or ceramic. Gravity or low pressure is used to fill the mold cavity.

Advantages

√ Better mechanical properties than sand casting

√ Improved surface finish and dimensional accuracy

√ Economical for medium to high production volumes

Limitations

√ Less suitable for highly complex geometries

√ Higher cost than sand casting

Common Applications

Automotive pistons, gear housings, wheels, industrial equipment parts.

Centrifugal Casting - For Hollow and Symmetrical Parts

Overview

Molten metal is poured into a rotating mold, where centrifugal force distributes the metal and forms the part. This method is ideal for cylindrical or tubular shapes.

Advantages

√ High-density castings with minimal impurities

√ Excellent mechanical properties

√ Suitable for high-strength applications

Limitations

√ Limited to symmetrical parts

√ Specialized equipment required

Common Applications

Pipes, rings, cylinders, bushings, flywheels.

Continuous Casting - Efficiency in Large-Scale Metal Production

Overview

Continuous casting, also known as strand casting, is a process where molten metal is solidified into a semi-finished billet, bloom, or slab for subsequent rolling in finishing mills. Unlike traditional casting methods that cast metal into discrete molds, continuous casting allows for the ongoing production of metal sections with consistent cross-sections.

Advantages

√ Highly efficient and cost-effective for large-scale production

√ Produces metal with uniform composition and excellent mechanical properties

√ Minimizes material waste and energy consumption

√ Reduces the need for intermediate processing like ingot remelting

Limitations

√ Limited to simple shapes such as slabs, billets, and blooms

√ Requires significant capital investment in equipment and infrastructure

√ Not suitable for producing intricate or custom-shaped parts directly

Common Applications

Steel and aluminum production for structural beams, flat rolled products, pipes, rails, and other bulk metal stock used in manufacturing and construction.

Shell Mold Casting - Combining Sand and Precision

Overview

Shell mold casting is a refined version of sand casting. It uses a resin-coated sand that is heated in a metal pattern to form a thin, hard shell.

Advantages

√ Better surface finish and accuracy than traditional sand casting

√ Suitable for medium to high-volume production

√ Good for small to medium-sized parts

Limitations

√ More expensive than green sand casting

√ Requires specialized sand and equipment

Common Applications

Camshafts, gear housings, connecting rods, brake components.

Choosing the Right Metal Casting Process

When selecting a metal casting service, consider these factors:

Material Type: Not all processes can accommodate ferrous metals like steel or cast iron.

Part Size and Geometry: Complex shapes may require investment casting, while large parts are better suited to sand casting.

Production Volume: Die casting is best for mass production, while sand and investment casting offer flexibility for low volumes.

Tolerance and Surface Finish Requirements: Tight tolerances and fine finishes often dictate the use of investment or die casting.

Cost Considerations: Balance tooling cost, per-unit cost, and post-processing needs.

Partnering with a Professional Metal Casting Supplier

A trusted and experienced metal casting manufacturer can help you navigate material selection, mold design, prototyping, and quality control. Whether you're looking for custom metal casting services, OEM aluminum casting, or bulk production of cast iron components, the right partner will provide engineering support, fast turnaround, and consistent quality.

Look for a supplier with:

√ ISO-certified quality management systems

√ In-house casting and machining capabilities

√ Full-service options from CAD design to finishing

√ Global shipping and logistics expertise

Final Thoughts

Metal casting is far from a one-size-fits-all solution. The wide variety of casting processes available today allows manufacturers to tailor production to exact specifications, whether for a small custom component or a mass-produced automotive part. By understanding the characteristics of each casting method and collaborating with a reliable casting service provider, you can optimize cost, performance, and delivery time.

Ready to start your next casting project?

Explore our full range of metal casting capabilities and connect with our engineering team to get a customized solution tailored to your needs.

Article Navigation

Article Navigation

Industries

Foundries

-

May.23, 2025

Casting Molds: The Heart of Precision Casting

READ MORE

-

May.13, 2025

Understanding Tolerance and Allowance in Casting: Key Concepts for Precision and Quality

READ MORE

-

May.07, 2025

Investment Casting vs. Sand Casting: Which Process Suits Your Project Best?

READ MORE

-

April.23, 2025

How to Find A Cost-Efficient Metal Casting Manufacturer?

READ MORE

-

April.01, 2025

What Factors Should Be Considered When Choosing A Metal Casting Method?

READ MORE

-

March.28, 2025

Everything You Need to Know About Die Casting!

READ MORE