Investment Casting vs. Sand Casting: Which Process Suits Your Project Best?

-

Home>

-

Blog>

-

Technology>

Investment Casting vs. Sand Casting: Which Process Suits Your Project Best?

When it comes to producing complex metal parts, investment casting and sand casting are two of the most commonly used methods. Both techniques have been refined over decades and offer unique benefits. But which one is better for your specific application? In this article, we compare investment casting vs. sand casting in detail - with a focus on ductile iron, one of the most widely used materials in precision components.

Investment Casting: The Precision - Oriented Process

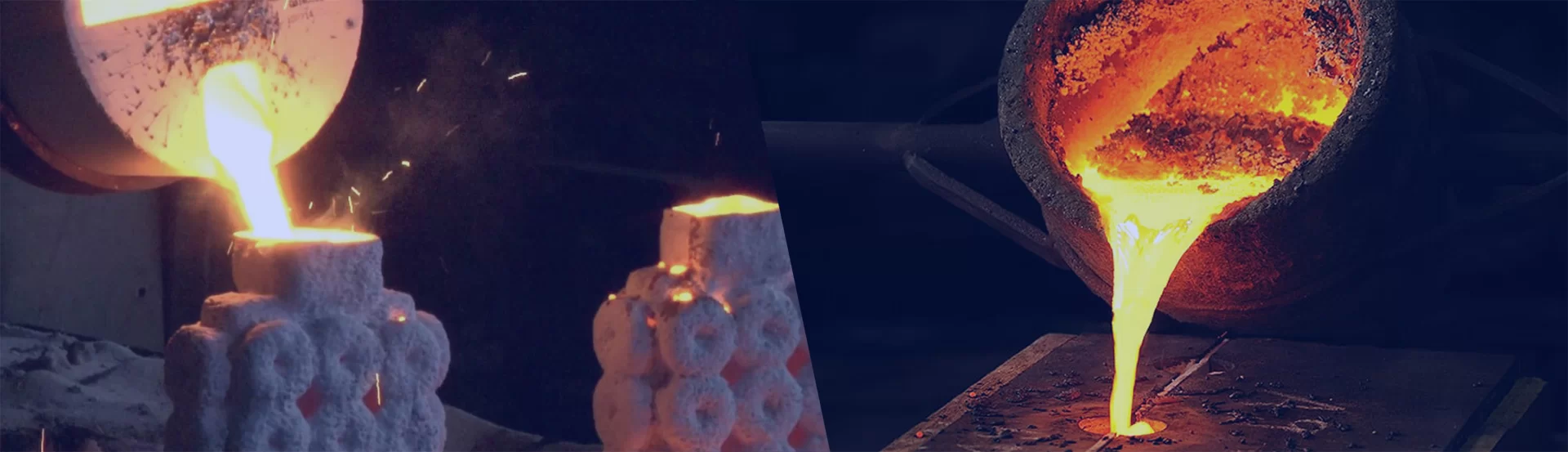

Investment casting, also known as lost-wax casting, is a highly precise method used to create complex metal parts. Investment casting factories begin by creating a wax pattern of the desired final product. This wax pattern is then coated with a ceramic shell. Once the ceramic shell has hardened, the wax is melted or burned out, leaving a hollow cavity in the shape of the original wax pattern. Molten metal, such as ductile iron in the case of ductile iron investment casting, is then poured into this cavity. After the metal cools and solidifies, the ceramic shell is removed, revealing the finished casting.

One of the key advantages of investment casting is its ability to produce parts with extremely high precision and intricate details. The smooth surface finish of investment-cast parts often means less post-processing is required. For example, in industries like aerospace and medical, where precision and a high - quality surface finish are critical, investment casting is the go-to method. Investment casting services can handle a wide range of materials, not just ductile iron, but also stainless steel, aluminum, and various alloys. This versatility makes it suitable for a diverse set of applications, from small, detailed components to larger parts with complex geometries.

Sand Casting: The Cost-Effective and Versatile Option

Sand casting, on the other hand, is a more traditional and widely used method. In sand casting, sand is compacted around a pattern to create a mold. The sand is typically mixed with clay and water to give it the necessary strength and workability. For ductile iron sand casting, the molten ductile iron is poured into this sand mold. Once the metal has cooled and solidified, the mold is broken apart to retrieve the casting.

The sand used in the mold can often be reused, which helps to keep costs down. Sand casting is highly versatile and can be used to produce a wide variety of part sizes, from small components to large industrial parts. It is also relatively easy to modify the mold design, making it a great option for prototypes or small-to-medium production runs where design changes may be frequent. However, compared to investment casting, sand-cast parts generally have a rougher surface finish and may require more post-processing to achieve a smooth surface.

Key Differences at a Glance

Feature | Investment Casting | Sand Casting |

Surface Finish | Excellent (Ra 3.2–6.3 μm) | Rougher (Ra 12.5–25 μm) |

Dimensional Accuracy | High (±0.1 mm) | Moderate (±0.5–1.0 mm) |

Part Complexity | Ideal for complex parts | Limited for intricate details |

Tooling Cost | Higher | Lower |

Production Volume | Medium to high | Low to high |

Lead Time | Longer | Shorter |

Comparing Ductile Iron Investment Casting and Ductile Iron Sand Casting

When it comes to ductile iron, both investment casting and sand casting have their own set of advantages. Ductile iron investment casting offers the ability to create near-net-shaped parts with excellent mechanical properties. The precision of the investment casting process allows for more complex designs in ductile iron parts, which is beneficial in applications where weight reduction and high strength-to-weight ratios are important, such as in automotive and some industrial equipment.

Ductile iron sand casting, on the other hand, is more cost-effective for larger parts and for applications where the part geometry is less complex. The simplicity of the sand casting process makes it a good choice for high volume production of more straightforward ductile iron components, like some agricultural machinery parts or large pipe fittings.

Factors to Consider When Choosing Between the Two

Precision and Complexity

If your project requires parts with intricate details, tight tolerances, and a smooth surface finish, investment casting is the clear winner. The ability to create complex shapes with high precision makes it ideal for parts in industries where performance and quality are non-negotiable.

Cost

For large-scale production of simple parts, sand casting is often more cost-effective due to lower tooling costs and the reusability of sand. However, for small-batch production of complex parts, investment casting may be more economical in the long run as it reduces the need for extensive post-processing.

Production Volume

Sand casting is well-suited for high volume production as the mold-making process is relatively quick and inexpensive. Investment casting, while it can be scaled up, may be more time-consuming and costly for very high-volume runs due to the more elaborate pattern-making and shell-building process.

Conclusion: Tailoring the Process to Your Needs

There's no one-size-fits-all answer when choosing between investment casting vs. sand casting. It ultimately comes down to your product's size, complexity, tolerance requirements, and budget.

Whether you're looking for precision ductile iron investment casting or high-volume sand castings, selecting a reliable supplier with flexible capabilities is key. A trusted investment casting service can also help you evaluate design feasibility, recommend the right alloy, and optimize production from start to finish.

Looking for guidance on your next casting project? Contact us today - our engineering team is ready to help you find the most cost-effective and performance-driven solution.

Article Navigation

Article Navigation

Industries

Foundries

-

April.23, 2025

How to Find A Cost-Efficient Metal Casting Manufacturer?

READ MORE

-

March.28, 2025

Everything You Need to Know About Die Casting!

READ MORE

-

March.26, 2025

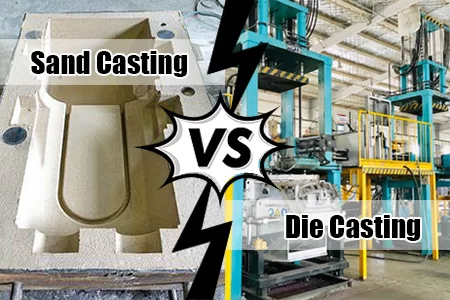

Sand Casting vs. Die Casting: Which is Right for Your Project?

READ MORE

-

March.25, 2025

CNC Cutting vs. Laser Cutting: Which One is Right for Your Project?

READ MORE

-

March.12, 2025

Applications of Stainless Steel Castings in Medical Devices

READ MORE

-

March.03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE