HULK Metal wants to be the best metal casting service supplier to let customers enjoy more thoughtful metal casting services. Benefit more people by changing metals.

Top Metal Casting Foundry

REQUEST A QUOTE

HULK METAL STRENGTHEN

HULK Metal increases the types of metal casting services and related services through three-dimensional integration. Let every customer enjoy thoughtful metal casting services. After more than 20 years of development, we have established a complete supply chain to complete your every metal casting order better.

When you choose HULK Metal as your metal casting service provider, you can enjoy faster delivery and lower prices. Let our engineers develop a more suitable solution for you.

Get Better Casting Solutions

HULK Metal increases the types of metal casting services and related services through three-dimensional integration. Let every customer enjoy thoughtful metal casting services. After more than 20 years of development, we have established a complete supply chain to complete your every metal casting order better.

When you choose HULK Metal as your metal casting service provider, you can enjoy faster delivery and lower prices. Let our engineers develop a more suitable solution for you.

TYPE OF METAL CASTING SERVICES

The metal casting services we provide are mainly divided into sand casting services, investment casting services, and die casting services according to the technology. The materials that can be cast are mainly iron, carbon steel, stainless steel, aluminum and its alloys, and copper and its alloys. You can click on the link below to learn more.

-

SAND CASTING

SERVICEWe master a variety of sand casting processes, such as silica sol, water glass, resin, and clay. According to metal castings’ complexity, precision, and performance requirements, choosing a more suitable casting process can reduce production costs effectively and improve efficiency. Contact us now and our technical team will formulate a complete solution according to the drawings and your specific requirements.

READ MORE

-

INVESTMENT CASTING

SERVICEWe select binders such as water glass, silica sol, and other shell materials according to metal castings‘ shape complexity, precision, and performance requirements and formulate a complete solution to carry out our investment casting services. We will complete the order at a lower cost and in a shorter time based on ensuring the quality of the castings. You can contact us to visit our factory online or in person.

READ MORE

-

LOST FOAM CASTING

SERVICELost foam casting uses foam plastic to make a casting model. After applying refractory material, use a vibration table to complete the mold without taking the model out. The metal pouring is completed under negative pressure, followed by cooling, cleaning, and finishing to complete the casting process.

READ MORE

-

MOLD MAKING

SERVICENo matter what kind of metal casting service, it needs to go through the step of mold making. For example, investment casting needs a mold for making wax patterns, and die casting needs a particular metal mold. As a professional metal casting service provider, we have a supply chain that covers mold manufacturing. With the same quality, lower-priced molds can be obtained with the help of our supply chain. If you need metal casting services, trust us.

READ MORE

-

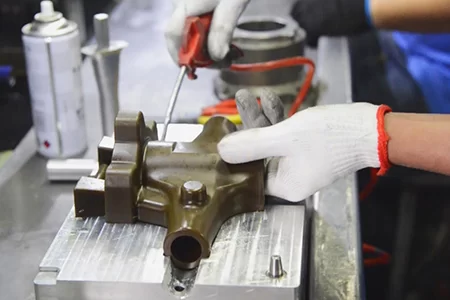

MACHINING

SERVICEAs another link in metal casting services, machining can further process castings' surface, shapes, and size to achieve higher precision, better surface roughness, etc. In addition to high-precision tools, first-class programmers and sophisticated equipment are also required, which we already have. Therefore, you can get more precise metal castings through HULK Metal's one-stop service.

READ MORE

Using the right technology to complete your order can help you complete your order faster and cheaper while maintaining quality and quantity. Contact us and let our engineers give you a suitable solution and quote.

HULK METAL SUPPLIES

BETTER CASTING SERVICE

Since 2000, HULK Metal (Qingdao Hulk Metal Technology Co., Ltd) has begun to focus on providing metal processing services to global customers. The business scope covers metal casting, metal forging, metal fabrication, and so on. We split metal casting services into a particular supply chain to provide more professional services. We continue to integrate the supply chain, as of today, we can already supply sand casting, investment casting, lost foam casting, and other services. By integrating the supply chain (which has direct access to raw material procurement, production, quality inspection, packaging, freight, and other processes),...

REQUEST A QUOTE

Foundry Show

INDUSTRIES WE SERVED

The casting services we supply have covered more than 20 machinery manufacturing industries, such as automobile manufacturing, mining machinery, textile machinery, and food machinery, as well as the construction industry, home appliance manufacturing, etc. Give us drawings or samples, and we can give you a solution and quotation. We support global shipping and online and on-site factory visits. Contact us now, and let’s start a unique metal casting service journey.

-

Agricultural Machinery Parts

Agricultural Machinery PartsThe manufacturing of Agricultural Machinery includes parts manufacturing and assembly. The processes required for parts manufacturing include casting and forging, stamping, heat treatment, machining, surface treatment, etc. For casting, selecting the appropriate process according to the shape, size, surface accuracy, and other requirements of agricultural machinery parts can save costs and time.

READ MORE

-

Food Processing Equipment Parts

Food Processing Equipment PartsHULK Metal has provided parts OEM services to dozens of well-known food machinery manufacturers. At present, we have used sand casting, investment casting, and die casting to produce food machinery accessories made of food-grade aluminum, iron, carbon steel, stainless steel, and other materials. Kindly contact our engineers for details.

READ MORE

-

Mining Machinery Parts

Mining Machinery PartsComplete production solutions, advanced metal foundries, strict management, and quality inspection processes allow customers to receive mining machinery parts with guaranteed quality and quantity more quickly while enjoying more thoughtful services.

READ MORE

More Results

You only need to provide drawings, and we will formulate solutions, calculate prices, and complete orders until delivery.

METAL CASTING NEWS

Here is a collection of various articles about metal casting, such as introductions to the casting process and materials. You can find what you need.

- News

- Technology

-

April 23, 2025

How to Find A Cost-Efficient Metal Casting Manufacturer?

READ MORE

-

April 14, 2025

CNC Milling vs. CNC Turning: Unraveling the Key Differences for Your Project

READ MORE

-

March 28, 2025

Everything You Need to Know About Die Casting!

READ MORE

-

March 26, 2025

Sand Casting vs. Die Casting: Which is Right for Your Project?

READ MORE

-

March 25, 2025

CNC Cutting vs. Laser Cutting: Which One is Right for Your Project?

READ MORE

-

March 18, 2025

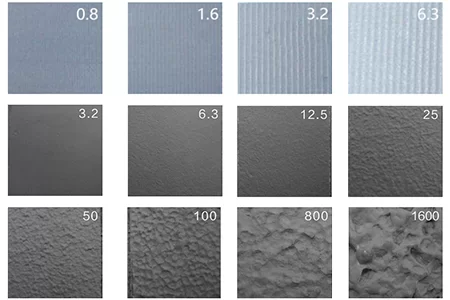

Surface Roughness Comparison of Castings with Different Materials and Processes

READ MORE

-

March 12, 2025

Applications of Stainless Steel Castings in Medical Devices

READ MORE

-

March 10, 2025

Achieving Precision in Metal Casting: Key Strategies for High-Quality Casting Parts

READ MORE

-

March 06, 2025

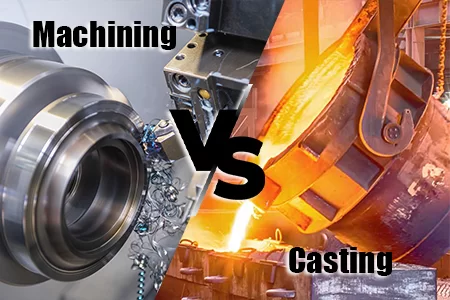

CNC Machining vs. Metal Casting: Unraveling the Differences for Optimal Manufacturing

READ MORE

-

March 03, 2025

Addressing Defects in Castings: A Comprehensive Guide

READ MORE

-

February 25, 2025

How to Compare Product Quality Between Different Casting Foundries?

READ MORE

-

February 14, 2025

What Are The Metal Casting Materials Commonly Used in Foundries?

READ MORE

-

January 20, 2025

Surface Treatments for Metals After Casting

READ MORE

-

January 09, 2025

How to Select The Right Raw Materials for Casting Foundries?

READ MORE

-

December 09, 2024

Differences in Wax Materials for Precision Casting

READ MORE

-

November 18, 2024

What Should Casting Manufacturers Pay Attention to in Production Management?

READ MORE

FREQUENTLY ASKED QUESTIONS

Here is a collection of questions about metal casting that HULK Metal customers have asked so far. You can find what you want here.

-

1. Castings' drawings (2D or 3D) If there are no drawings, samples can be provided

2. Material (if not on the drawing)

3. Quantity

4. Delivery terms

Our colleagues will give you a better quote after understanding your needs more deeply.

-

The general process of casting production is to make molds, melt raw materials, pour, cool, clean, and finishing to finish products. Many casting processes are derived from this process. This answer briefly summarizes this content. Kindly search for other content on the website to fully understand it.

-

We need to decide based on the complexity of the casting, the quantity you require, the quantity of a single delivery, and many other factors. For a specific delivery period, our sales manager will lead the service team to develop a solution that satisfies you based on your requirements.

-

Yes, we support return, replenishment, and exchange services. Any products with quality defects will be dealt with in the best possible manner after being confirmed. We will actively deal with any of your questions. For more than 20 years, the feedback we have received from our customers on our products has been consistently positive.

-

T/T(For big orders, 30-90 days can be acceptable), L/C, for other methods please contact our sales manager.

-

You only need to give us the following information to get a simple quote:

1. Drawings (2D or 3D) If there are no drawings, samples can be provided.

2. Material (if not on the drawing)

3. Quantity

4. Delivery terms

Our colleagues will give you a more detailed quote after understanding your needs more deeply.

-

Aluminum is extremely popular. It has a low density, good corrosion resistance, and high thermal conductivity, making it suitable for a wide range of applications, from aircraft parts to cookware. Iron, especially cast iron, is another commonly cast metal. It has excellent castability and high compressive strength and is often used in engine blocks, pipes, and machinery parts. Copper and its alloys, such as brass and bronze, are also widely cast. They offer good electrical and thermal conductivity as well as attractive aesthetic properties, which is why they are used in electrical components, decorative items, and musical instruments.

-

The general process for making sand casting molds is to make two upper and lower sandboxes, make a casting pattern, mix sand and binder, fill it into the sandbox with the pattern and vibrate it, take out the pattern, put it in the sand core and close the box. The method or whether to remove the pattern needs to be determined according to the casting process. For example, the pattern of investment casting is taken out through high-temperature evaporation, while the pattern of lost foam casting does not need to be taken out. We will introduce it in more detail below.